Method for measuring concentration of germanium or/and tin impurity in crystalline silicon

A technology of impurity concentration and measurement method, which is applied in the field of measurement of germanium or/and tin impurity concentration in crystalline silicon, can solve problems such as difficulty in detection of impurity concentration of germanium-tin master alloy, and achieve complex detection methods, cost reduction, and small deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. The measuring method of germanium or / and tin impurity concentration in crystalline silicon, comprises the steps:

[0031] 1. Add 0.005 grams of boron powder with a purity of 6N-7N and 2000 grams of germanium with a purity of 5N-7N into 150,000 grams of solar-grade polysilicon raw materials, and form a silicon melt through the Czochralski single crystal manufacturing method (CZ method). Body, under the protective atmosphere of argon, the P-type germanium-containing master alloy silicon rod is prepared;

[0032] 2. Cut the germanium-containing master alloy silicon rod in step 1 into germanium-containing master alloy silicon wafers with a thickness of 3 mm by internal circle cutting or multi-wire cutting, and then use the solar-grade silicon material cleaning process to clean the germanium-containing master alloy silicon wafers. surface cleaning;

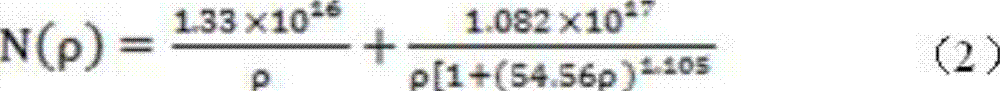

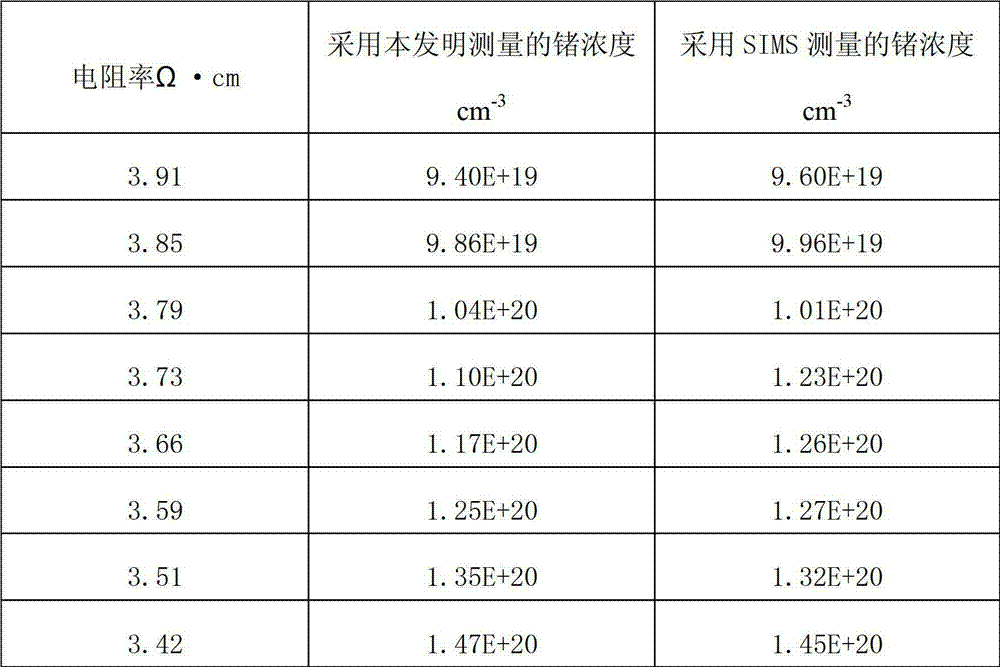

[0033] 3. Utilize the four-probe method to measure the resistivity ρ of the germanium-containing master alloy s...

Embodiment 2

[0048] Embodiment 2. The measuring method of germanium or / and tin impurity concentration in crystalline silicon, comprises the steps:

[0049] 1. Add 0.005 grams of phosphorus with a purity of 6N-7N and 2000 grams of tin with a purity of 6N-7N into 150,000 grams of solar-grade polysilicon raw materials, and form a silicon melt through the Czochralski single crystal manufacturing method (CZ method). Body, under the protective atmosphere of argon, the N-type tin-containing master alloy silicon rods were prepared;

[0050] 2. Cut the tin-containing master alloy silicon in step 1 into a tin-containing master alloy silicon wafer with a thickness of 1mm by means of internal circle cutting, multi-wire cutting, etc., and then use a solar-grade silicon material cleaning process to clean the tin-containing master alloy Silicon wafer surface cleaning;

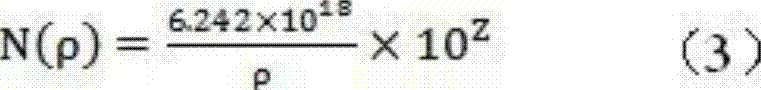

[0051] 3. Use the four-probe method to measure the resistivity ρ of the tin-containing master alloy silicon chip obtained in step 2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com