Totally closed sound barrier

A sound barrier and fully enclosed technology, applied in construction, noise absorption devices, etc., can solve the problems of poor sound insulation and sound absorption performance, reduced sound absorption effect, weakened noise reduction performance of sound barriers, etc., and achieve excellent impact resistance Performance, avoiding noise leakage, and avoiding the effect of reducing sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

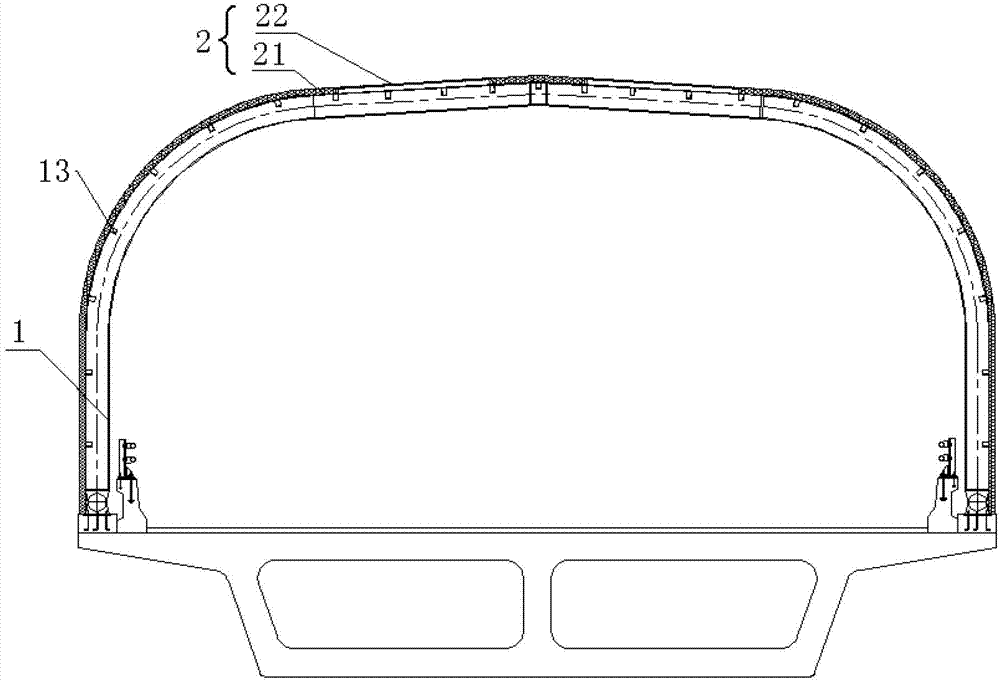

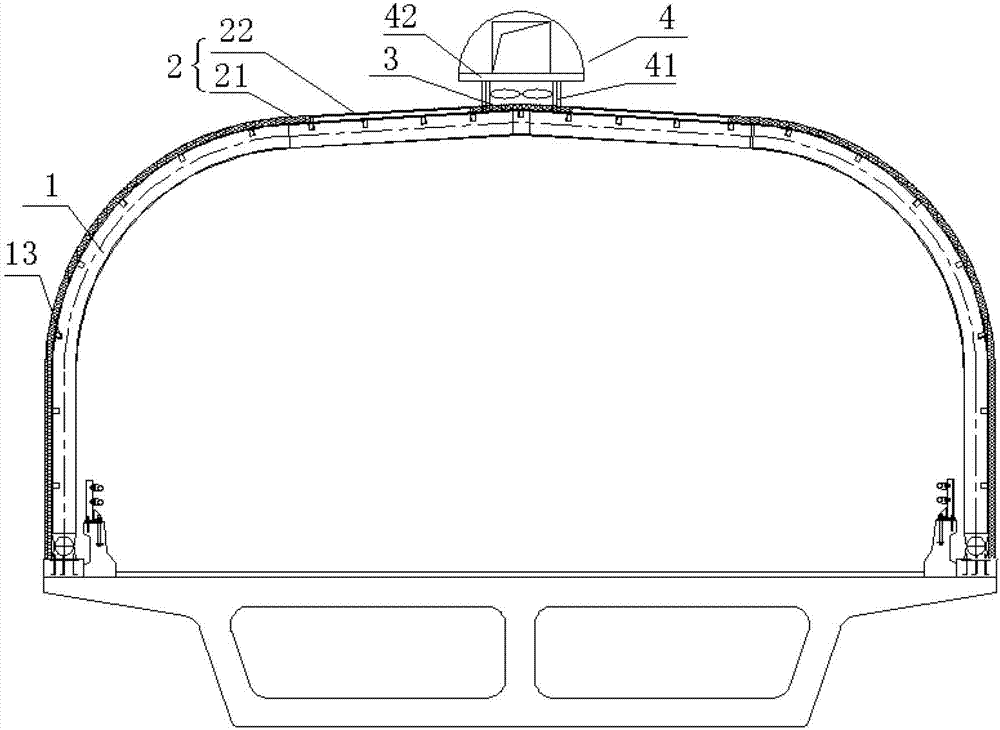

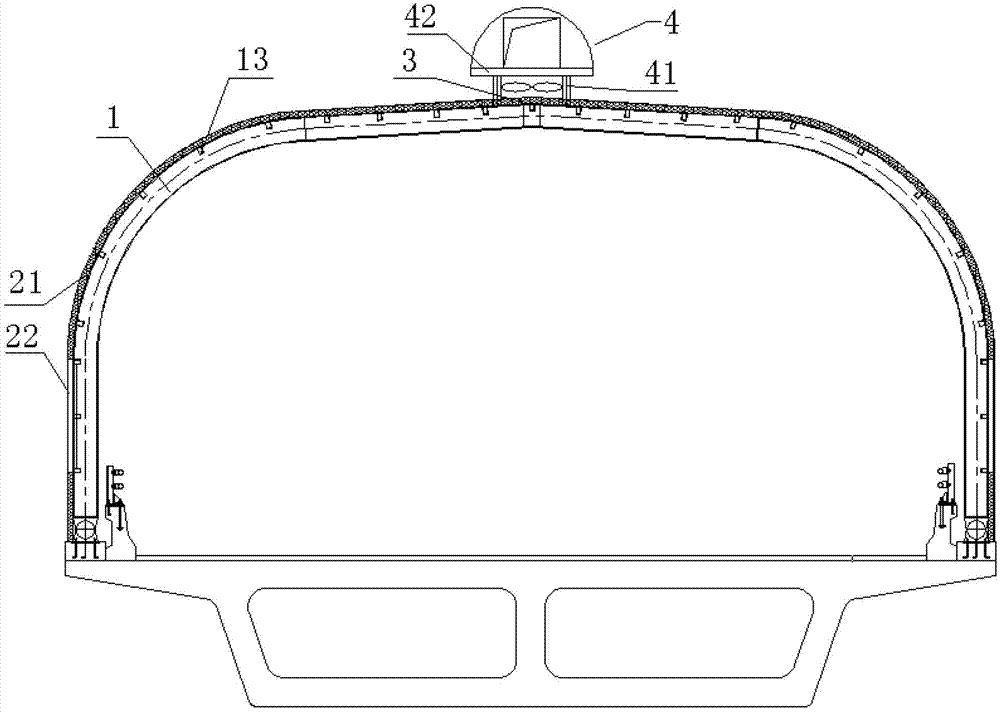

[0041] like figure 1 As shown in the structure, a fully enclosed sound barrier provided by the present invention includes a door-type steel frame 1 and a sound barrier plate 2 laid on the door-type steel frame 1. The sound barrier plate 2 includes a sound-absorbing sound barrier plate 21 and a transparent The type sound barrier plate 22, the sound insulation and absorption sound barrier plate 21 and the transparent type sound barrier plate 22 are installed on the outside of the door type steel frame 1 together.

[0042]For the fully enclosed sound barrier with a short length, it is not necessary to provide vents on the portal steel frame 1, and the convective air at the entrance and exit of the sound barrier can meet the internal air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com