Steel box component and steel box-concrete combined U-shaped girder composed of same

A technology for concrete and steel parts, applied in bridges, building components, bridge parts, etc., can solve the problems of large anti-corrosion and fire prevention area, prolonged construction period, high steel consumption, etc., achieve good friction and occlusion effect, reduce reinforcement area , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

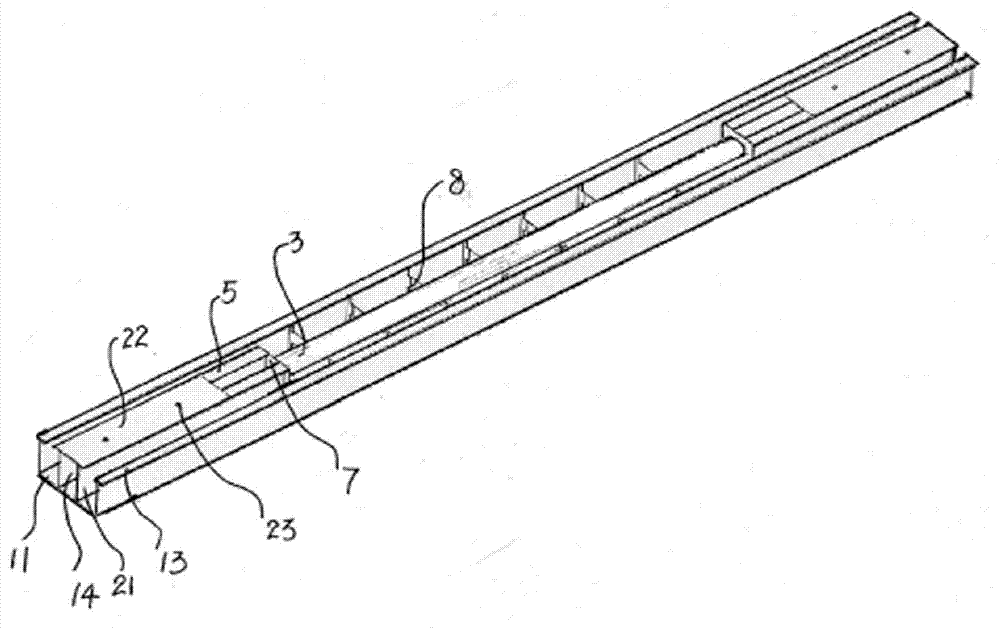

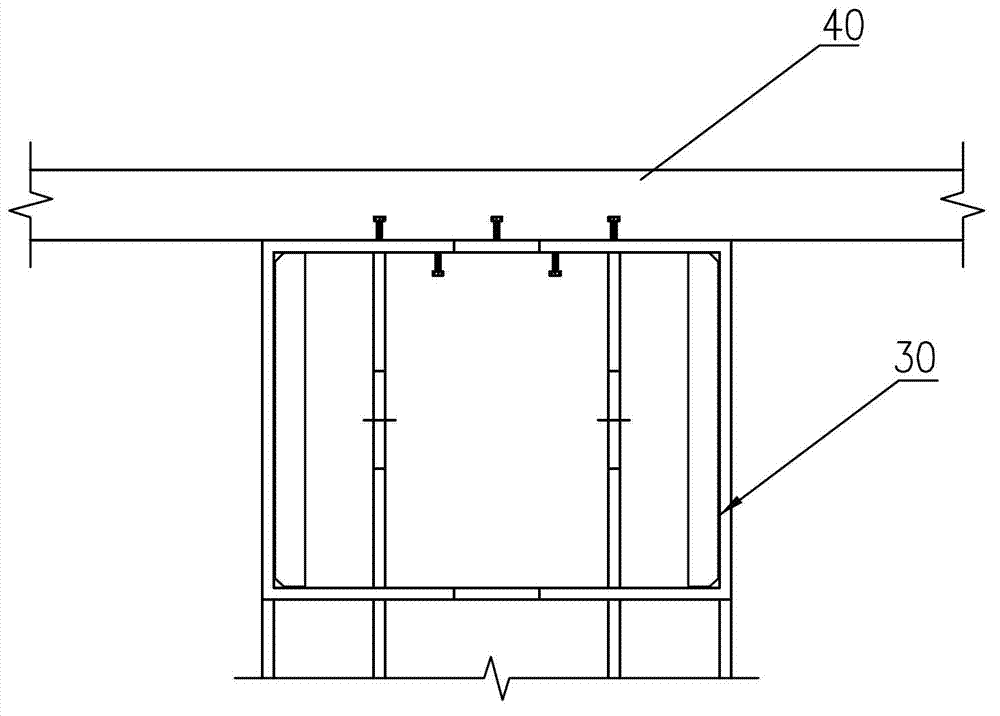

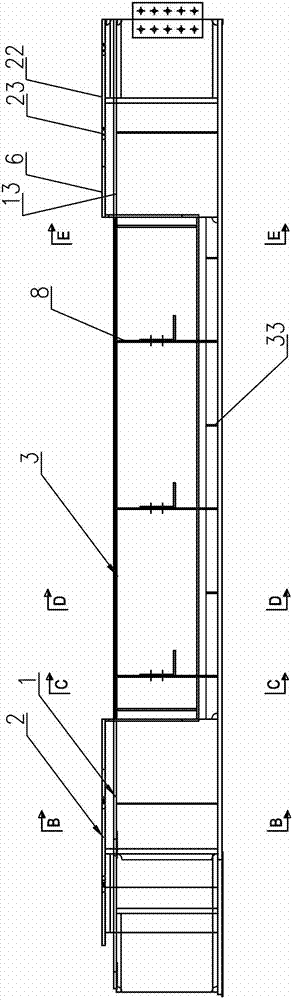

[0045] Such as Figure 2-13 As shown, it is a steel box assembly of the present invention, which is mainly composed of a U-shaped steel part 1, an n-shaped steel part 2 and a steel pipe 3 located at the mid-span position of the U-shaped steel part 1, and the length of the steel pipe accounts for half of the length of the U-shaped steel part The U-shaped steel part 1 is composed of an elongated base plate 11, a pair of outer plates 12 and an upper flange 13. The outer plates 12 are vertically arranged on both sides of the base plate 11, and the upper flange 13 is arranged on the top of the outer plate 12 of the U-shaped steel part. On the surface, the upper flange 13 is arranged horizontally along the longitudinal direction of the outer plate 12; the n-shaped steel part 2 is composed of a pair of vertically arranged elongated inner plates 21 and a top plate 22 arranged on the upper end of the inner plate 21, and the n-shaped steel part 2 is arranged on In the U-shaped space at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com