Preparation method of okra wine

A technology of pulping and alcoholic fermentation, which is applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc. The effect of rich okra flavor, high yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of beverage type okra low-alcohol health wine, carried out according to the following steps:

[0035] 1) Raw material selection: choose fresh, mildew-free, non-rotten okra tender pods that are 5 days after flowering as raw materials;

[0036] 2) Pre-treatment: Put the okra pods in ZnCl containing 0.05‰ 2 and 0.10‰CuSO 4 Soak in the solution of 25 ℃ for 3hr, then add the soaked okra into the aqueous solution with pH value of 7.5 and blanch at 95 ℃ for 3min, the pH value adopts Na 2 CO 3 adjust;

[0037] 3) Pulping: add water and make pulp according to the ratio of 2 times the weight of okra tender pods, so that the slurry after pulping is as fine as possible, which is beneficial to the enzymatic hydrolysis process;

[0038] 4) Enzymatic hydrolysis: The okra slurry after pulping has a high viscosity, which is not conducive to fermentation. Using compound enzyme treatment can effectively reduce the viscosity and facilitate fermentation. Add 0.5% (b...

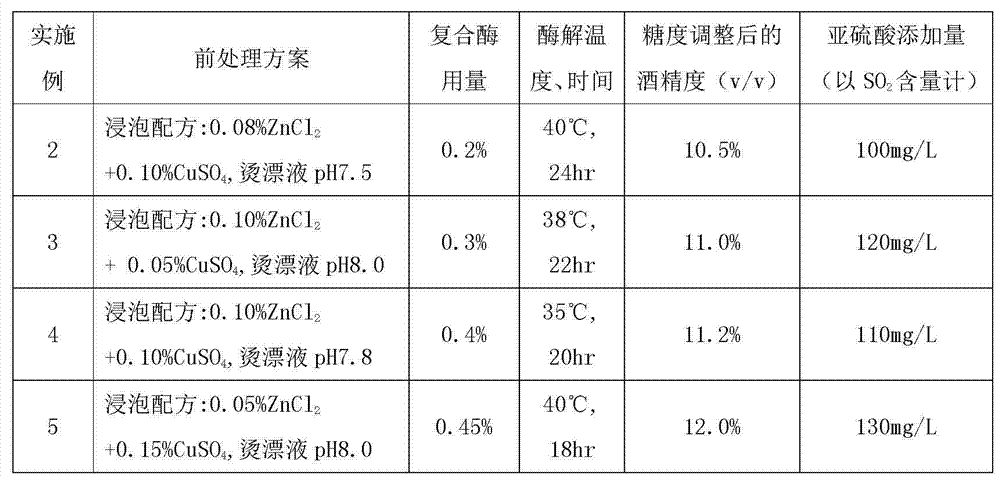

Embodiment 2-5

[0046] Embodiment 2-5: Carry out according to the following steps and process parameters, and the rest are the same as embodiment 1.

[0047]

[0048] The preparation method of the beverage-type okra low-alcohol health wine has low production cost and high production efficiency, and 1 ton of raw materials can produce about 1.5-2 tons of beverage-type okra low-alcohol health wine, and the alcohol content can reach 10.0-12.0% (by volume). percent concentration meter).

Embodiment 6

[0050] A preparation method of beverage type okra low-alcohol health wine, carried out according to the following steps:

[0051] 1) Raw material selection: choose fresh, mildew-free, non-rotten okra tender pods that are 7 days after flowering as raw materials;

[0052] 2) Pretreatment: add 0.05‰ of ZnCl before okra pulping 2 and 0.05‰CuSO 4 Treat (soak 4hr at room temperature at 25°C), then add the soaked okra to an aqueous solution with a pH value of 8.0 and blanch at 100°C for 5min, and the pH value adopts Na 2 CO 3 adjust;

[0053] 3) Pulping: add water and make pulp according to the ratio of 2 times the weight of okra tender pods, so that the slurry after pulping is as fine as possible, which is beneficial to the enzymatic hydrolysis process;

[0054] 4) Enzymatic hydrolysis: The okra slurry after pulping has a high viscosity, which is not conducive to fermentation. Using compound enzyme treatment can effectively reduce the viscosity and facilitate fermentation. Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com