Acrylic fiber waste water treatment method

An acrylic fiber and waste water technology, which is applied in textile industry waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve microbial film damage, failure to guarantee normal nitrification and denitrification reactions, ammonia nitrogen pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Step 1: Lead an acrylic fiber production plant into a regulating pool to regulate water quality and quantity. At the same time, sodium hydroxide is added to the adjustment tank to adjust the pH value of the acrylic fiber wastewater to about 12.

[0083] Step 2, passing the acrylic fiber wastewater treated in step 1 into an ultrasonic hydrolysis tank. Ultrasonic frequency is 22kHz, sound energy intensity is 10W / cm 2 , the reaction time is 2h, and the reaction conditions are normal temperature and pressure. Macromolecular organic molecules in sewage undergo ring-opening and chain-breaking reactions under the extreme physical conditions generated by ultrasound, transforming them into small molecular substances that are easily biodegradable.

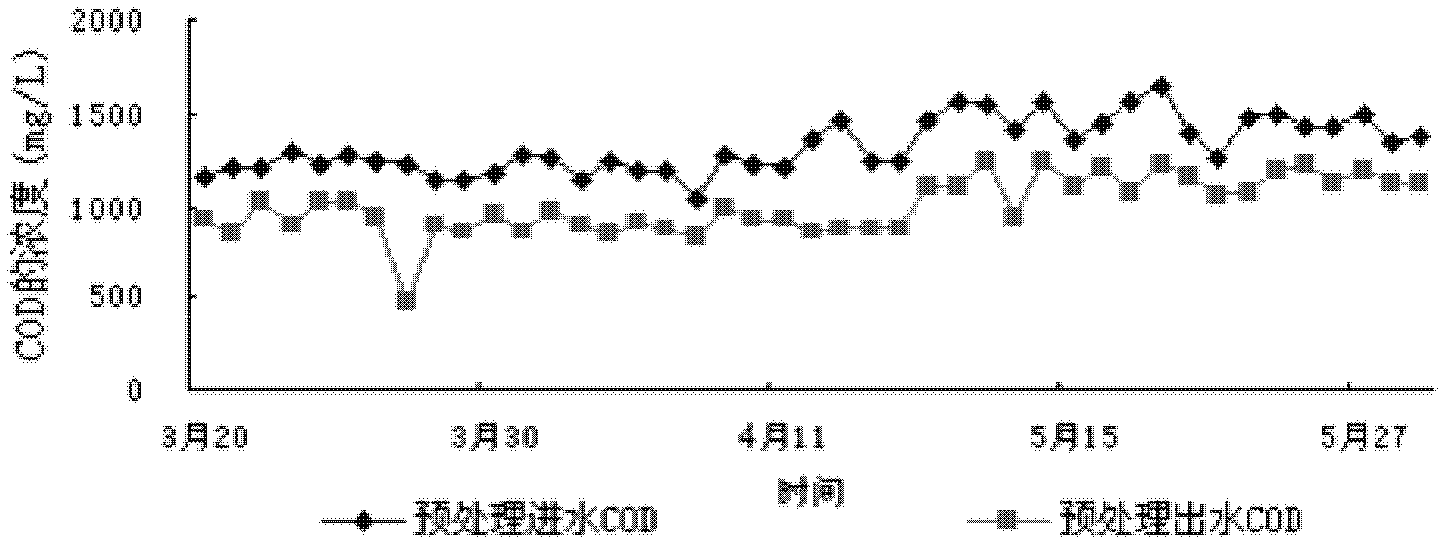

[0084] Combine Table 2 and image 3 The effect of preprocessing in the examples will be described.

[0085] Table 2 Acrylic fiber wastewater adopts different pretreatment water quality of influent and effluent

[0086]

[0087...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com