Black water-based color paste for acrylic stock solution coloring and preparation method of black water-based color paste

A technology of water-based color paste and stock solution coloring, which is applied in the fields of dyeing, textiles and papermaking, etc., to achieve the effect of improving poor hydrophilicity, small particle size and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

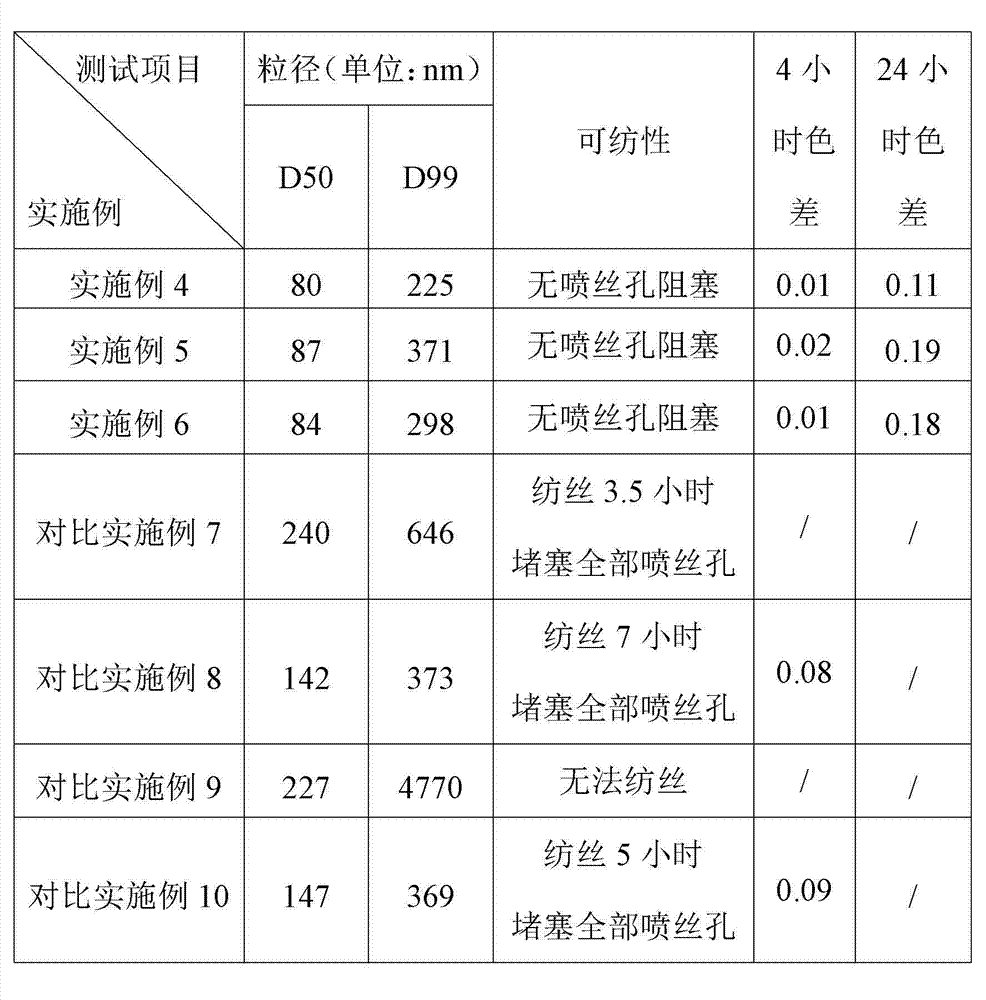

Examples

Embodiment 1

[0032] This embodiment is an oxidation embodiment of carbon black. Stir and disperse 1000g carbon black, 5000g deionized water, and 50g hydrogen peroxide in the reactor at a speed of 5r / min for 30min, use an ozone generator to provide 3% ozone mass concentration, and enter the reactor from the bottom at a speed of 5L / min. After 5 hours of treatment , adjust the pH value to 7.5 with 10% sodium hydroxide solution, filter and dry.

Embodiment 2

[0034] This embodiment is an oxidation embodiment of carbon black. Stir and disperse 800g carbon black, 5000g deionized water, and 20g sodium persulfate in the reactor at a speed of 5r / min for 1h, provide 3% ozone mass concentration with an ozone generator, and enter the reactor from the bottom at a speed of 5L / min. After 3 hours, adjust the pH value to 7.2 with 15% potassium hydroxide solution, filter and dry.

Embodiment 3

[0036] This embodiment is an oxidation embodiment of carbon black. Stir and disperse 500g carbon black, 5000g deionized water, and 25g sodium hypochlorite in the reactor at a speed of 5r / min for 45min, use an ozone generator to provide 3% ozone mass concentration, and enter the reactor from the bottom at a speed of 5L / min. After 2 hours of treatment , adjust the pH value to 8.0 with 20% potassium hydroxide solution, filter and dry.

[0037] Embodiments 4~6 and comparative examples 7~10 are all produced according to the following processing steps:

[0038] (1) Knead the oxidized carbon black and pigment surface treatment agent in a kneader for 0.5~1 hour;

[0039] (2) Dissolve the dispersant and sodium thiocyanate in co-solvent and deionized water, and disperse in the disperser at a speed of 500-800r / min for 15-20min to obtain a premixed solution;

[0040] (3) Reduce the speed of the disperser to 300~400r / min, add the carbon black kneaded in (1) to the premixed liquid obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com