Horizontal type molten pool smelting process outside furnace and dedicated device thereof

A molten pool smelting and special equipment technology, which is applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of low copper content in slag and short process flow, and achieve the effects of low smoke and dust rate, saving investment and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

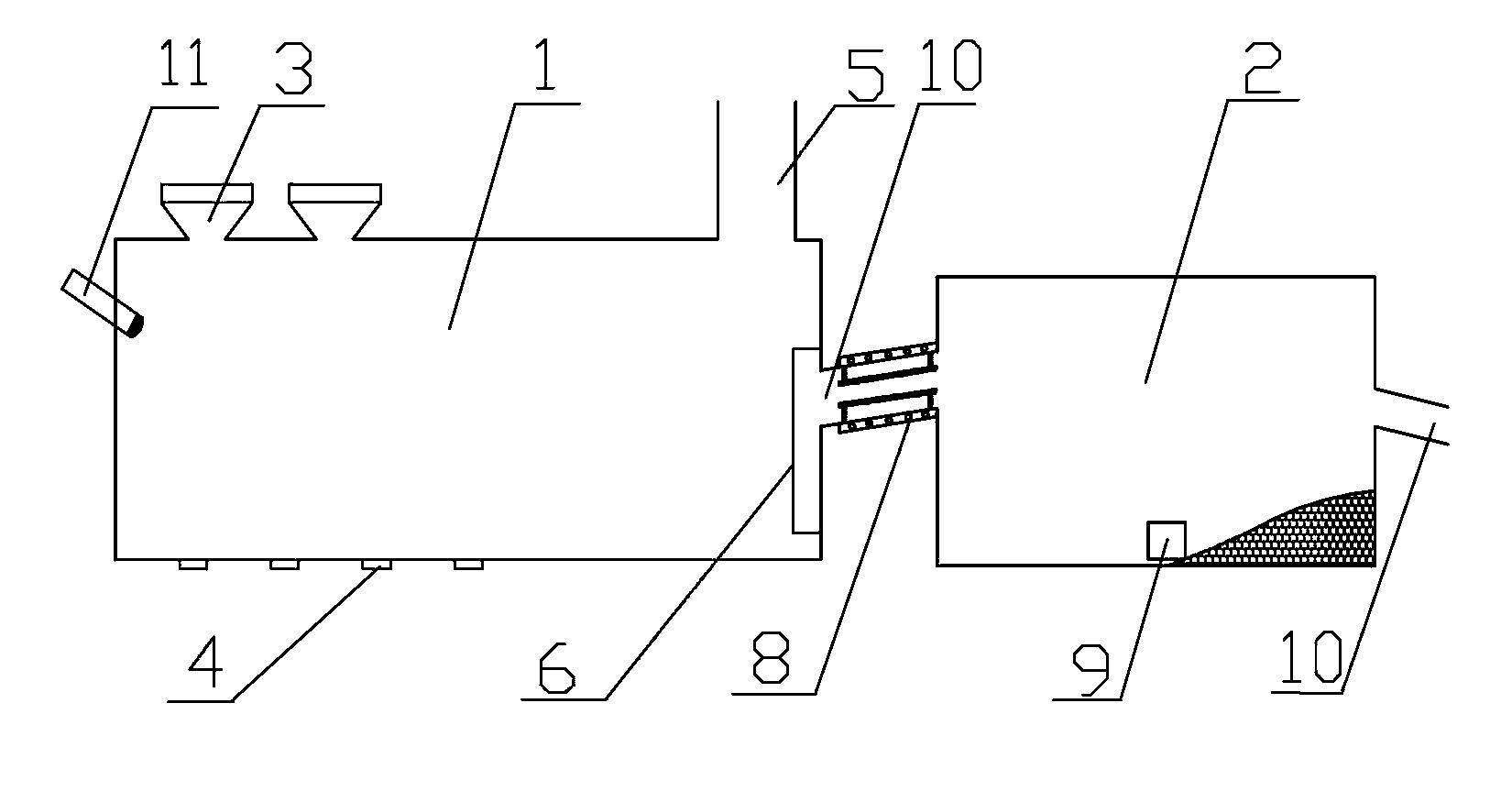

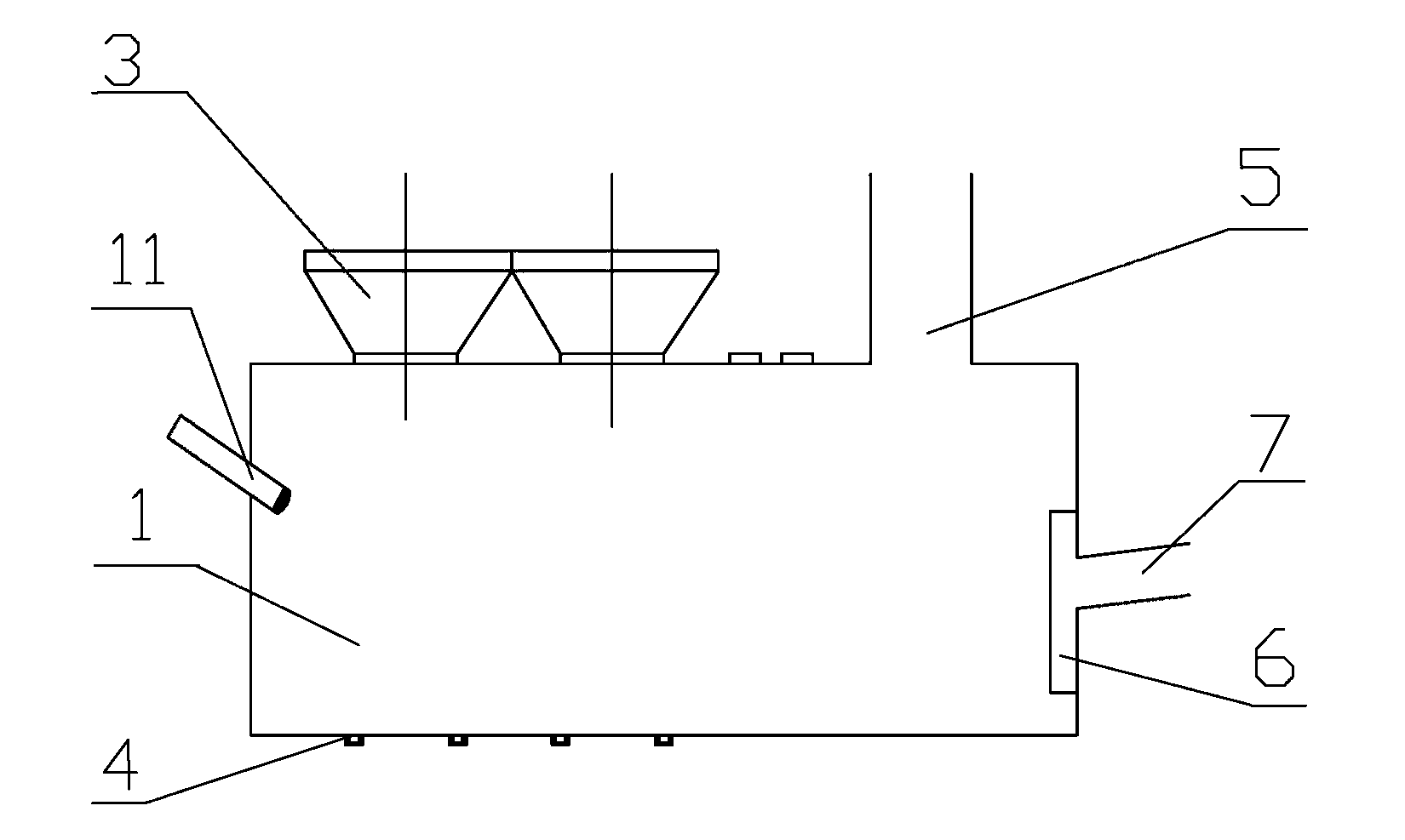

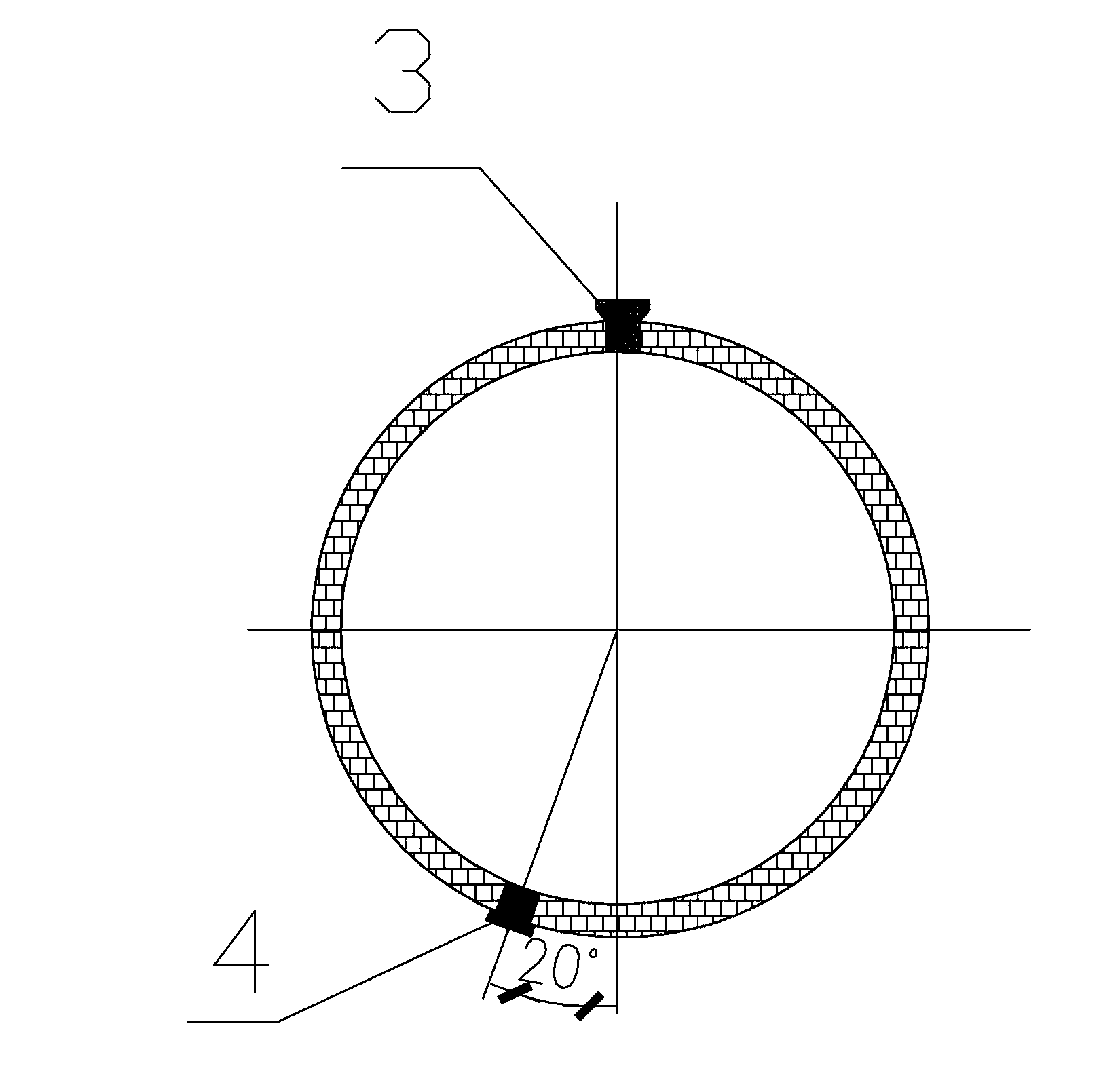

[0039] In order to make the advantages and features of the present invention easier to understand, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. However, the examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

[0040] This kind of outside-furnace separation horizontal melting pool smelting process, after mixing copper concentrate, quartz stone, limestone, cold material, etc., they are continuously and uniformly added to the molten pool melting furnace through a belt feeder, and the oxygen inserted at the bottom is used The gun drum injects high-pressure oxygen-enriched air and compressed air to form a strong agitation for the melt in the molten pool, so that the mass transfer and heat transfer process in the molten pool can be carried out rapidly, and a series of chemical reactions are completed to generate copper matte, smelting slag and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com