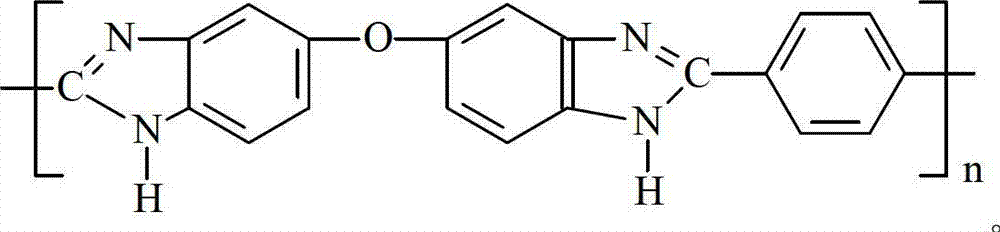

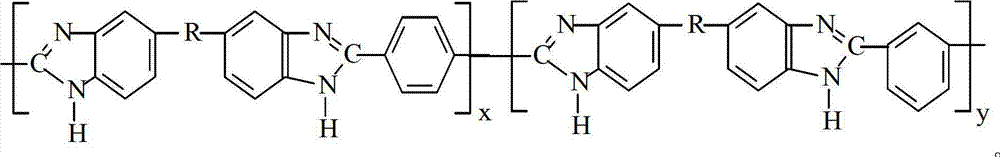

Benzimidazole-epoxy matrix resin and preparation method thereof

A technology of epoxy matrix and benzimidazole, which is applied in the field of organic polymer resin and its preparation, can solve the problems of unsatisfactory heat resistance and achieve excellent dimensional stability, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

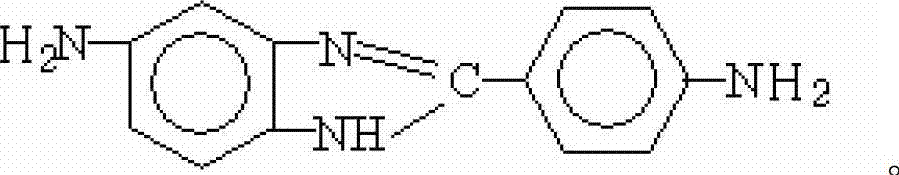

[0030]Mix 100.0 g of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPP) with 5.0 g of 2-(4-amino Phenyl)-5-aminobenzimidazole (APABI) was put into the reaction kettle, heated to 70°C and stirred for 15 minutes, then added 21.5 grams of resorcinol diglycidyl ether, 100.0 grams of methyl ethyl ketone and 40.0 grams of 1,4 -Dioxane, stir evenly, obtain 266.5 grams of A component, be denoted as A1, resin mass percent content is 47.5%;

[0031] Mix 100.0 g of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPP) with 8.0 g of 2-(4-amino Phenyl)-5-aminobenzimidazole (APABI) was put into the reaction kettle, heated to 80°C and stirred for 30 minutes, then added 5.0 grams of resorcinol diglycidyl ether and 15.0 grams of 3,4-epoxy Cyclohexanecarboxylic acid-3',4'-epoxycyclohexylmethyl ester, 120.0 g of methyl ethyl ketone and 60.0 g of chloroform were stirred evenly to obtain 308.0 g of component A, denoted as A2, and the resin mass percentag...

Embodiment 2

[0037] The A component of Example 1, i.e. A1, A2, A3 and B component, i.e. B1, B2, B3, were mixed in proportion and stirred evenly to obtain a series of benzimidazole-epoxy matrix resins, denoted as BIE-1~BIE-9, as shown in Table 1.

[0038] Table 1 series of benzimidazole-epoxy base resin (BIE) formulations

[0039] BIE

Embodiment 3

[0041] Take an appropriate amount of benzimidazole-epoxy matrix resin (BIE), that is, BIE-1~BIE-9, and apply them evenly on standard stainless steel test pieces, and after airing at room temperature for 0.5 hours, stack and clamp Put it into a blast oven for curing: start from room temperature to 70°C, heat for 1 hour, continue to heat up to 100°C, heat for 1 hour, and cool to room temperature naturally. The tensile shear strength (σ) test was carried out at room temperature (25°C) and high temperature (150°C) using an electronic tensile machine, and the results are shown in Table 2.

[0042] Take an appropriate amount of benzimidazole-epoxy matrix resin (BIE), that is, BIE-1~BIE-9, push the film on the polytetrafluoroethylene film, put it in a vacuum drying oven, and make it into a size of 5mm× For a square sample of 5mm x 1mm, the curing process is as follows: start from room temperature to 70°C, heat for 1 hour, continue to heat up to 100°C, heat for 1 hour, and naturally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com