Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

A composite material, high-barrier technology, used in military puncture-resistant, high-barrier camouflage camouflage composite materials and their preparation, anti-static, tear-resistant fields, can solve the problems of easy puncture, poor flexibility, and poor barrier properties of protective materials. Excellent anti-static, enhanced flexibility, anti-kneading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

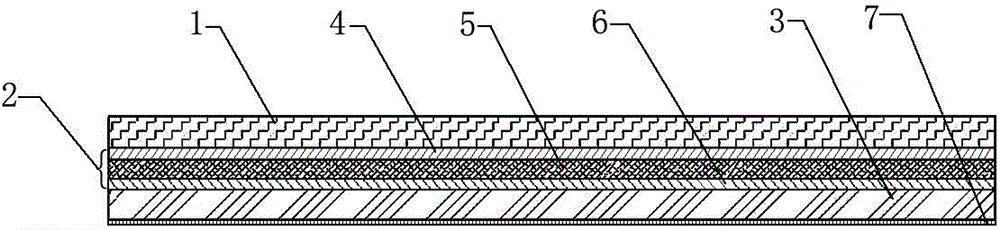

[0031] Such as figure 1 As shown, the camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat seal layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer; To the bottom are polyethylene terephthalate film 4 with a thickness of 12 μm, aluminum foil 5 with a thickness of 7 μm, and polyamide film 6 with a thickness of 15 μm; the heat-sealing layer 3 is thermoplastic polyurethane with a thickness of 135 μm Elastomeric membrane. Each layer is bonded together with an adhesive, and then heat-pressed and compounded by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

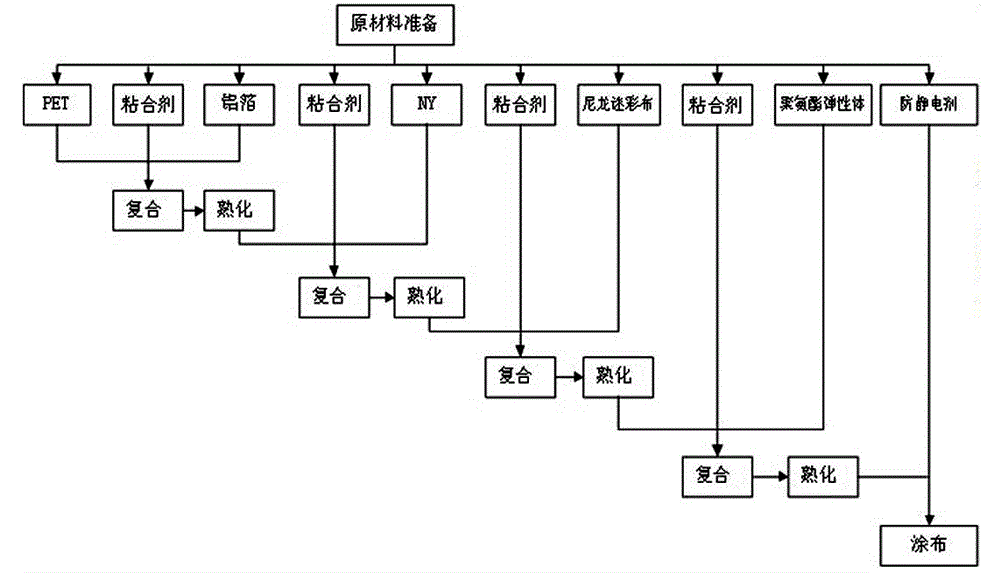

[0032] Such as figure 2 Shown, the preparation technology of camouflage camouflage composite material of the present invention is:

[0033] (1...

Embodiment 2

[0038] The camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat seal layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer; the high barrier layer 2 is sequential from top to bottom It is a polyethylene terephthalate film 4 with a thickness of 12 μm, an aluminum foil 5 with a thickness of 7 μm, and a polyamide film 6 with a thickness of 15 μm; the heat-sealing layer 3 is a thermoplastic polyurethane elastomer film with a thickness of 140 μm . Each layer is bonded together with an adhesive, and then heat-pressed and compounded by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

[0039] The preparation technology of camouflage camouflage composite material of the present invention is:

[0040] (1) Co...

Embodiment 3

[0045] The camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat-sealing layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer, and its lower surface is coated with a thickness of 5 μm Polyurethane elastomer coating; the high barrier layer 2 from top to bottom is a polyethylene terephthalate film 4 with a thickness of 12 μm, an aluminum foil 5 with a thickness of 7 μm, and a polyamide film 6 with a thickness of 15 μm; The heat-sealing layer 3 is a thermoplastic polyurethane elastomer film with a thickness of 130 μm. Each layer is bonded together with an adhesive, and then heat-pressed and compounded by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

[0046] The preparation technology of camouflage c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com