All-steel load-bearing radial tire belt rubber

A belt rubber and radial tire technology, applied in the rubber field, can solve the problems of low adhesion between rubber and steel wire, quality problems of tire finished products, endangering the health of operators, etc. The effect of protecting the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

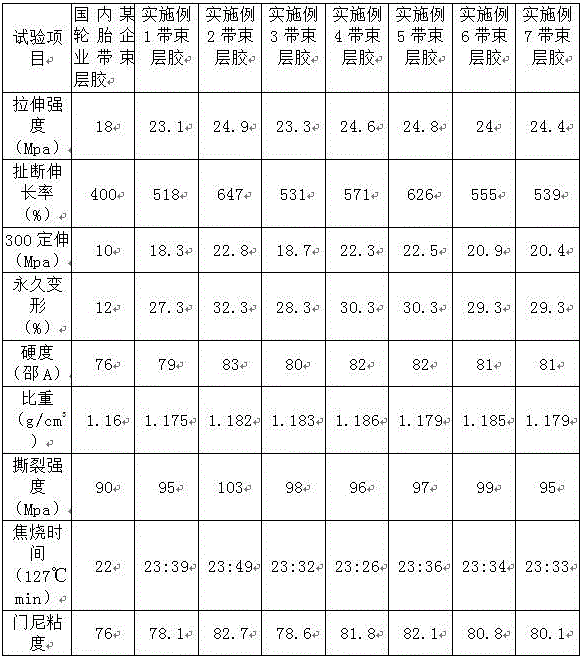

Embodiment 1

[0023] Embodiment 1, a kind of belt ply rubber of all-steel radial truck tire, its tire tread rubber is made up of the raw material of following parts by weight: natural rubber SMR20 86 parts, carbon black N375 30 parts, white carbon black 7 parts, indirect zinc oxide 5 parts, anti-aging agent 4020 1.3 parts, adhesive resin PN760 1.16 parts, cobalt salt 0.8 parts, adhesive RA65 2.5 parts, accelerator NOBS 0.4 parts, accelerator NS 0.3 parts, insoluble sulfur OT-20 3 parts, anti-scorch Agent CTP 0.09 parts.

Embodiment 2

[0024] Embodiment 2, a kind of belt ply rubber of all-steel radial truck tire, its tire tread rubber is made up of the raw material of following parts by weight: natural rubber SMR20 100 parts, carbon black N375 42 parts, white carbon black 10 parts, indirect zinc oxide 8 parts, anti-aging agent 4020 2.5 parts, adhesive resin PN760 1.88 parts, cobalt salt 1.2 parts, adhesive RA65 5 parts, accelerator NOBS 0.7 parts, accelerator NS0.6 parts, insoluble sulfur OT-20 5.5 parts, anti-corrosion Coke agent CTP 0.15 parts.

Embodiment 3

[0025] Embodiment 3, a kind of belt ply rubber of all-steel radial truck tire, its tire tread rubber is made up of the raw material of following parts by weight: natural rubber SMR20 114 parts, carbon black N375 55 parts, white carbon black 13 parts, indirect zinc oxide 11 parts, anti-aging agent 4020 3.7 parts, adhesive resin PN760 2.6 parts, cobalt salt 1.6 parts, adhesive RA65 7.5 parts, accelerator NOBS 1 part, accelerator NS 0.9 parts, insoluble sulfur OT-20 8 parts, anti-scorch Agent CTP 0.21 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com