Method for synchronously measuring various elements in metallurgical sundries

A technology for elements and miscellaneous materials, applied in the field of simultaneous determination of multiple elements in metallurgical miscellaneous materials, can solve the problems of difficulty in meeting the requirements of multi-element analysis, cumbersome photometric methods, and inapplicability to metallurgical miscellaneous materials, etc. Quality, extended reach, easy-to-master effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Optimizing instrument parameter is to satisfy the necessary condition of analytical test, with regard to the optimization reason of instrument parameter among the present invention, detailed description is as follows:

[0019] 1. Selection of analytical lines

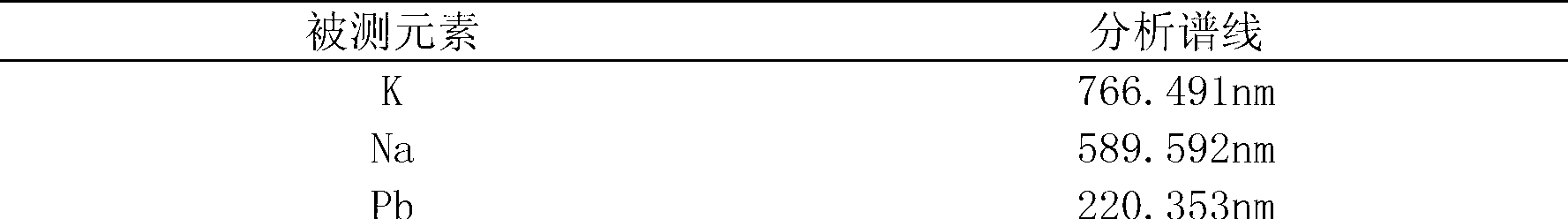

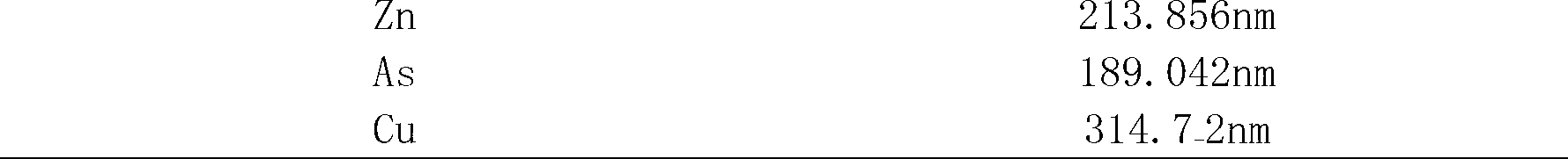

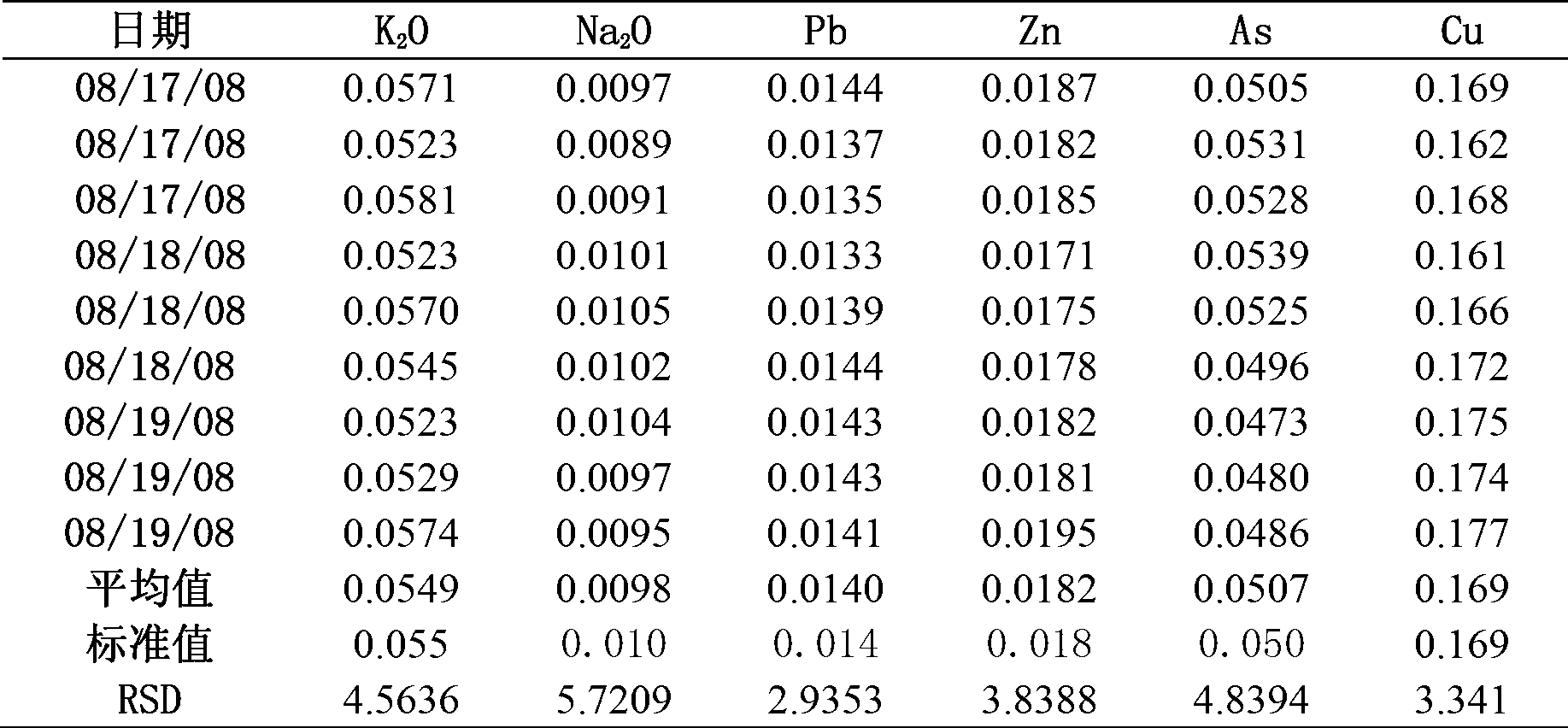

[0020] For the selection of analytical spectral lines, usually according to the content of the element to be measured and the interfering elements in the sample, the spectral line with high emission net intensity, high signal-to-background ratio, and less interference from coexisting elements is selected as the analytical line of the element to be measured. The experiment comprehensively compares multiple spectral lines of each determined element, and the best analytical spectral lines for each element are shown in Table 1.

[0021] Table 1. Selection of analytical lines

[0022]

[0023]

[0024] 2. Selection of high frequency power

[0025] After the ionization of alkali metal elements, the external ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com