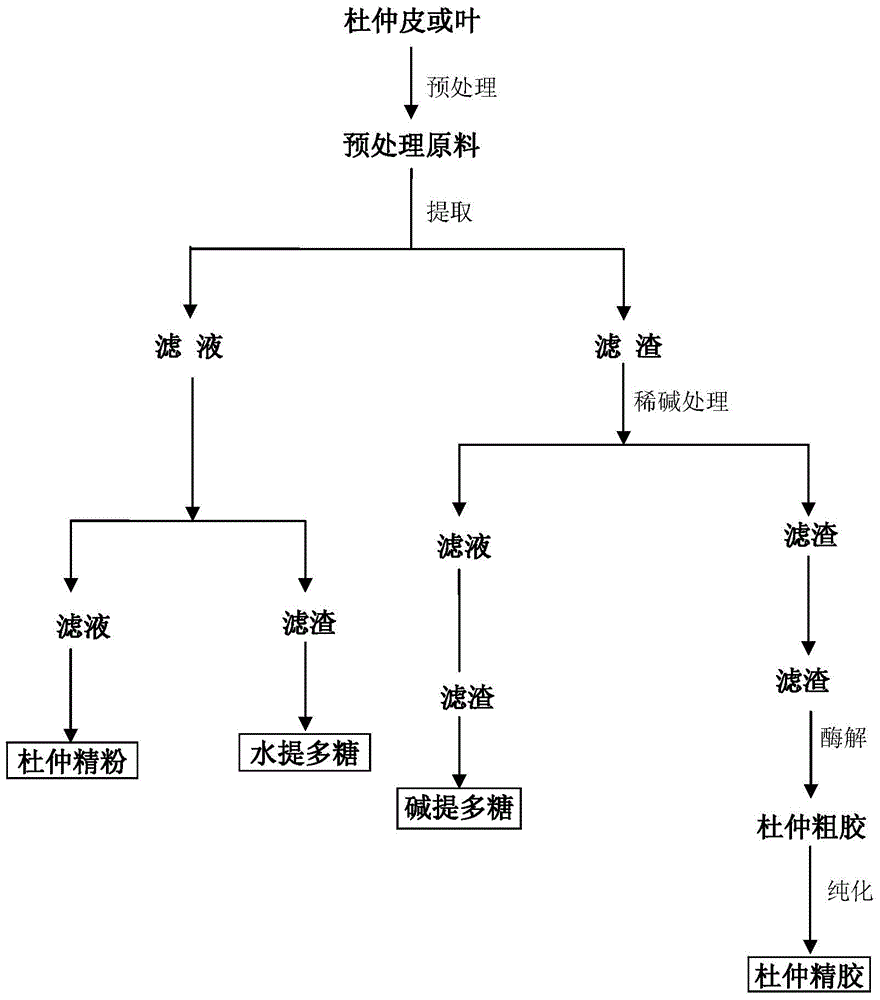

A kind of co-production extraction and separation method of eucommia fine powder, eucommia polysaccharide and eucommia gum

A technology of eucommia fine powder and separation method, which is applied in the direction of medical formula, medical preparations containing active ingredients, plant/algae/fungus/moss components, etc., which can solve the problem of low-cost utilization of eucommia gum and structural changes of eucommia gum , long period of Eucommia gum, etc., to achieve the effect of comprehensive development and utilization, short extraction and separation time, and clear solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Pre-treatment steps: After removing impurities, the leaves of Eucommia ulmoides are passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and exposed to the sun; the dried leaves of Eucommia ulmoides are mechanically crushed to a particle size of 10 mesh, and placed in a dry and cool place for later use .

[0040] (2) Extraction step: mix the eucommia leaves treated in step (1) according to the ratio of solid to liquid 1:20, extract at 60°C for 3 hours, filter the extract, and pump it to the storage tank for the second time When extracting, mix according to the ratio of solid to liquid of 1:5, and the extraction temperature and time are the same as the first time; the solution in the two extraction processes is pure water.

[0041] (3) Tube membrane filtration step: the mixed solution extracted in step (2) is removed and filtered by tube membrane filtration, wherein the tube membrane molecular weight cut-off is 20000D.

[0042] (...

Embodiment 2

[0056] (1) Pre-treatment step: After removing impurities, the leaves of Eucommia ulmoides are passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and exposed to the sun; the dried leaves of Eucommia ulmoides are mechanically crushed to 18 meshes, and placed in a dry and cool place for later use.

[0057] (2) Extraction step: mix Eucommia leaves treated in step (1) according to the ratio of solid to liquid ratio of 1:10, extract at 65°C for 2.5h, filter the extract, and pump it to the liquid storage tank for two During the second extraction, mix according to the ratio of solid to liquid of 1:10, and the extraction temperature and time are the same as the first time; the solution is pure water during the two extractions.

[0058] (3) Tube membrane filtration step: the mixed solution extracted in step (2) is removed and filtered by tube membrane filtration, wherein the tube membrane molecular weight cut-off is 25000D.

[0059] (4) Finished pr...

Embodiment 3

[0073](1) Pre-treatment steps: After removing impurities, the dried bark of Eucommia is passed the inspection according to the quality requirements of the Chinese Pharmacopoeia, and exposed to the sun; the dried bark of Eucommia is mechanically crushed to 20 meshes, and placed in a dry and cool place spare.

[0074] (2) Extraction step: mix the bark of Eucommia ulmoides treated in step (1) according to the ratio of material to liquid ratio of 1:15, extract at 70°C for 2 hours, filter the extract, and pump it to the liquid storage tank for the second time When extracting, mix according to the ratio of solid to liquid of 1:15, and the extraction temperature and time are the same as the first time; the solution is pure water during the two extraction processes.

[0075] (3) Tube membrane filtration step: the mixed solution extracted in step (2) is removed and filtered by tube membrane filtration, wherein the tube membrane molecular weight cut-off is 30000D.

[0076] (4) Finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com