Method for serging shuttleless sleeve band for heavy parachute rope

A parachute and seaming technology, which is applied in the direction of trimming, fabric, heating/cooling fabric, etc., can solve the problem of unstable belt edge structure, and achieve the effect of stable and reliable belt edge structure, no deformation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

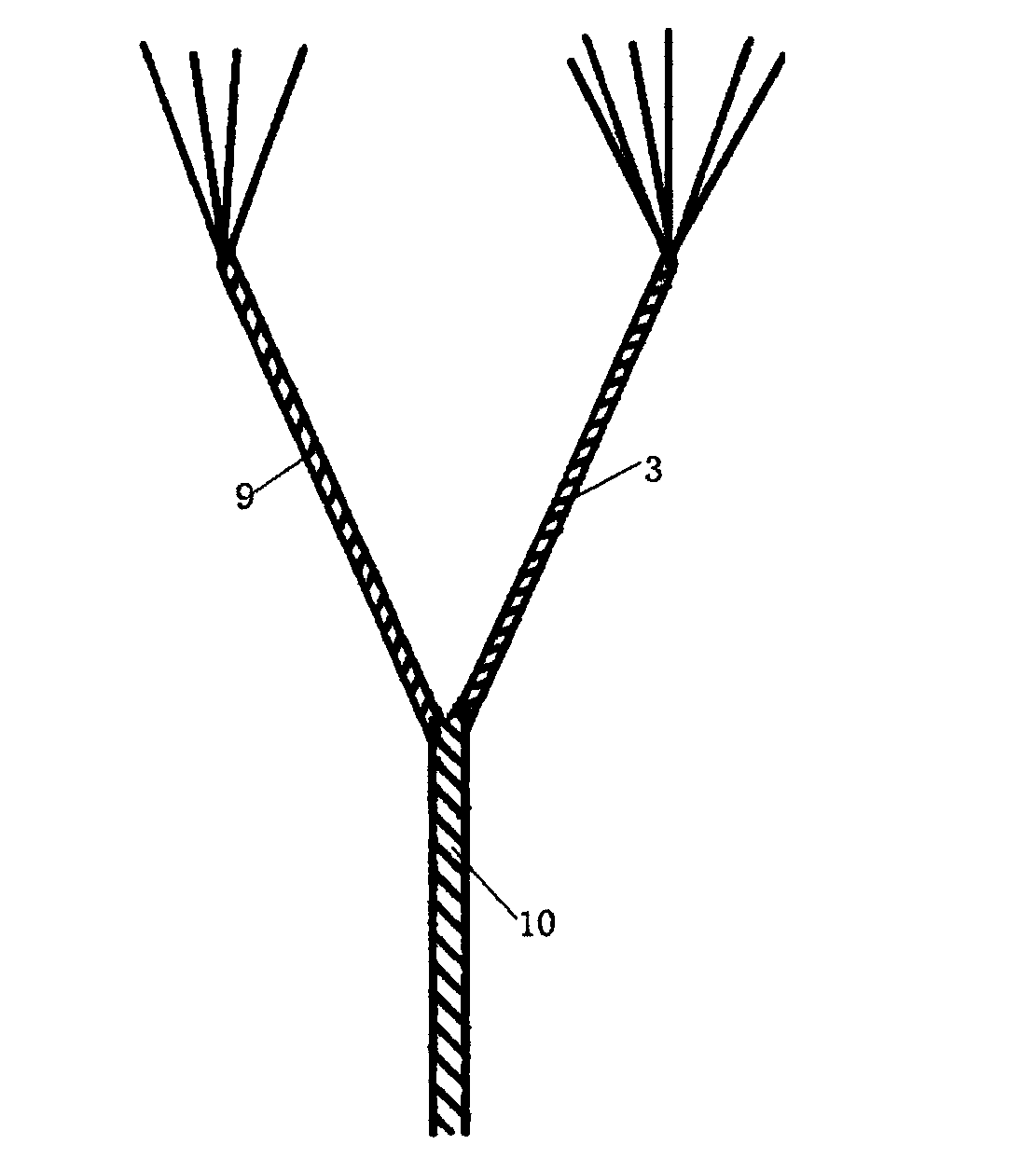

[0012] refer to figure 1 , figure 2 . In a preferred embodiment described below, the weaving equipment is a selected high-speed shuttleless weft insertion loom. Before weaving heavy-duty parachute ropes with shuttleless sleeves, first choose 70D / 18f (77dtex) hot-melt wires and brocade wires as raw materials for the overlock thread 3, according to figure 2 The principle shown is that the original seaming thread similar to the warp and weft threads and the low-melting point hot-melt multifilament 9 similar to the original seaming thread are twisted and combined into a hot-melt fiber seaming thread 10, and then combined with the warp thread 1 and the weft thread 2 to be machined Weaving. By shuttleless loom, according to figure 1 According to the principle shown, using the mutual movement of the weft inserting needle 6 and the overlock knitting edge 7, the crochet needle 8 of the knitting sock needle 4 and the knitting needle latch needle 5 work together to transfer the wef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com