Preparation method of general purpose pitch-based carbon fiber

A pitch-based carbon fiber, general-purpose technology, applied in the chemical characteristics of fibers, the processing of tar pitch/petroleum pitch/natural pitch, and the processing of tar pitch/petroleum pitch/natural pitch by distillation, etc. Melt spinnability, low spinnability and other problems, to achieve the effect of good quality, good continuity and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

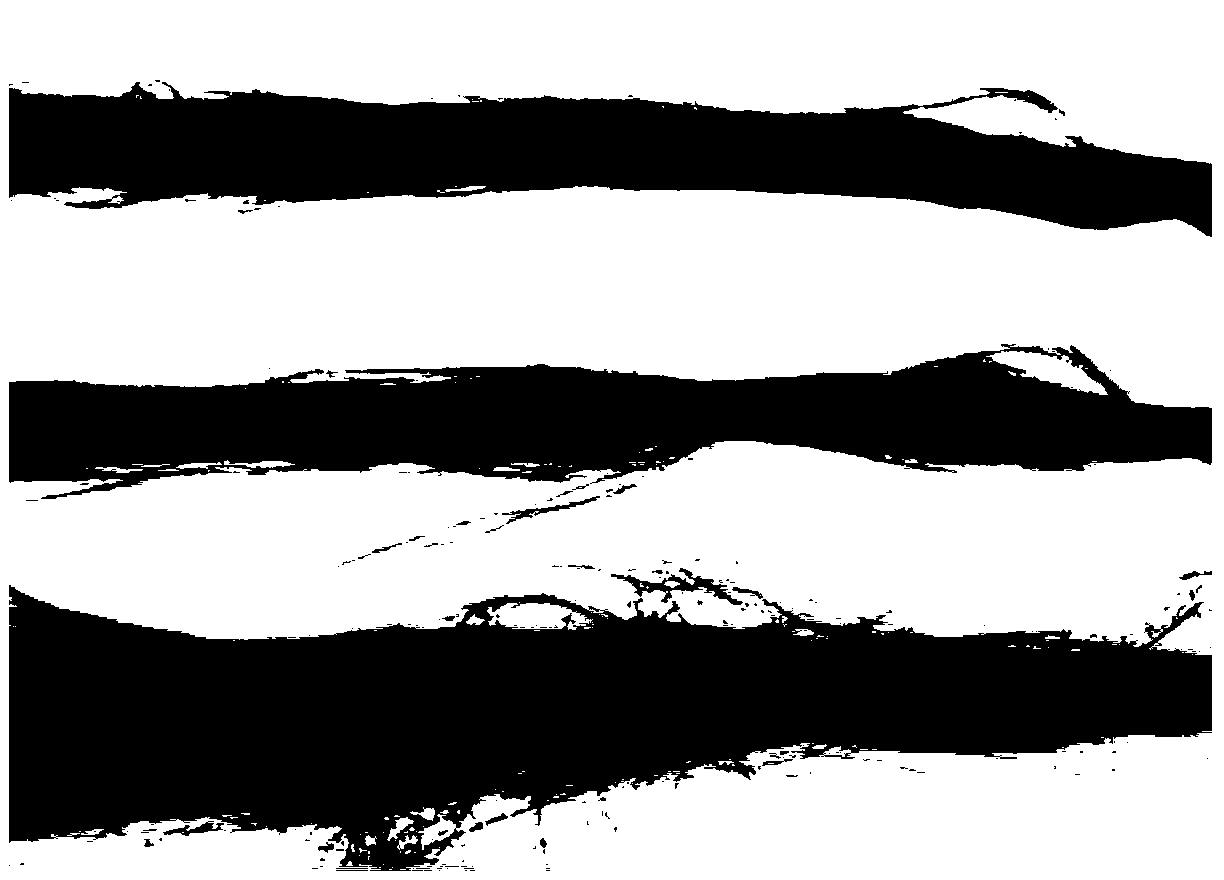

Image

Examples

Embodiment 1

[0033] Taking 150g of raw coal tar soft pitch as an example, the method for preparing general-purpose pitch-based carbon fibers consists of the following steps:

[0034] (1) heat treatment

[0035] Take 150g of coal tar soft asphalt with a softening point of 59°C, put it in a high-pressure reactor, and heat it to 390°C under the protection of nitrogen. The nitrogen flow rate is 85mL / min, the stirring speed is 350r / min, stirring, and reacting for 60min.

[0036] (2) Thermal filtration

[0037] Let the reaction product of step (1) stand for 30 minutes, the upper bitumen and the coke-forming components are separated, and the upper bitumen is poured into a hot filter kettle, the filter screen of the hot filter kettle is 600 mesh, the temperature is 360°C, and the pressure is 0.5MPa , to remove the coke-forming components in the upper bitumen.

[0038] (3) Distillation under reduced pressure

[0039] Put the bitumen from which the coke components were removed in step (2) in a hi...

Embodiment 2

[0049] Taking 150g of raw coal tar soft pitch as an example, the method for preparing general-purpose pitch-based carbon fibers consists of the following steps:

[0050] (1) heat treatment

[0051] Take 150g of coal tar soft pitch with a softening point of 59°C, put it in a high-pressure reactor, and heat it to 380°C under the protection of nitrogen, with a nitrogen flow rate of 80mL / min, a stirring speed of 300r / min, stirring, and reacting for 80min.

[0052] (2) Thermal filtration

[0053] Let the reaction product of step (1) stand for 15 minutes, the upper bitumen and the coke-forming components are separated, and the upper bitumen is poured into a hot filter kettle, the filter screen of the hot filter kettle is 400 mesh, the temperature is 350°C, and the pressure is 0.8MPa , to remove the coke-forming components in the upper bitumen.

[0054] (3) Distillation under reduced pressure

[0055] Put the bitumen from which the coke components were removed in step (2) in a hig...

Embodiment 3

[0065] Taking 150g of raw coal tar soft pitch as an example, the method for preparing general-purpose pitch-based carbon fibers consists of the following steps:

[0066] (1) heat treatment

[0067] Take 150g of coal tar soft pitch with a softening point of 59°C, put it in a high-pressure reactor, and heat it to 400°C under the protection of nitrogen, with a nitrogen flow rate of 90mL / min, a stirring speed of 400r / min, stirring, and reacting for 50min.

[0068] (2) Thermal filtration

[0069] Let the reaction product of step (1) stand for 40 minutes, the upper bitumen and the coke-forming components are separated, and the upper bitumen is poured into the hot filter kettle, the filter screen of the hot filter kettle is 400 mesh, the temperature is 390°C, and the pressure is 0.1MPa , to remove the coke-forming components in the upper bitumen.

[0070] (3) Distillation under reduced pressure

[0071] Put the bitumen from which the coke components were removed in step (2) in a h...

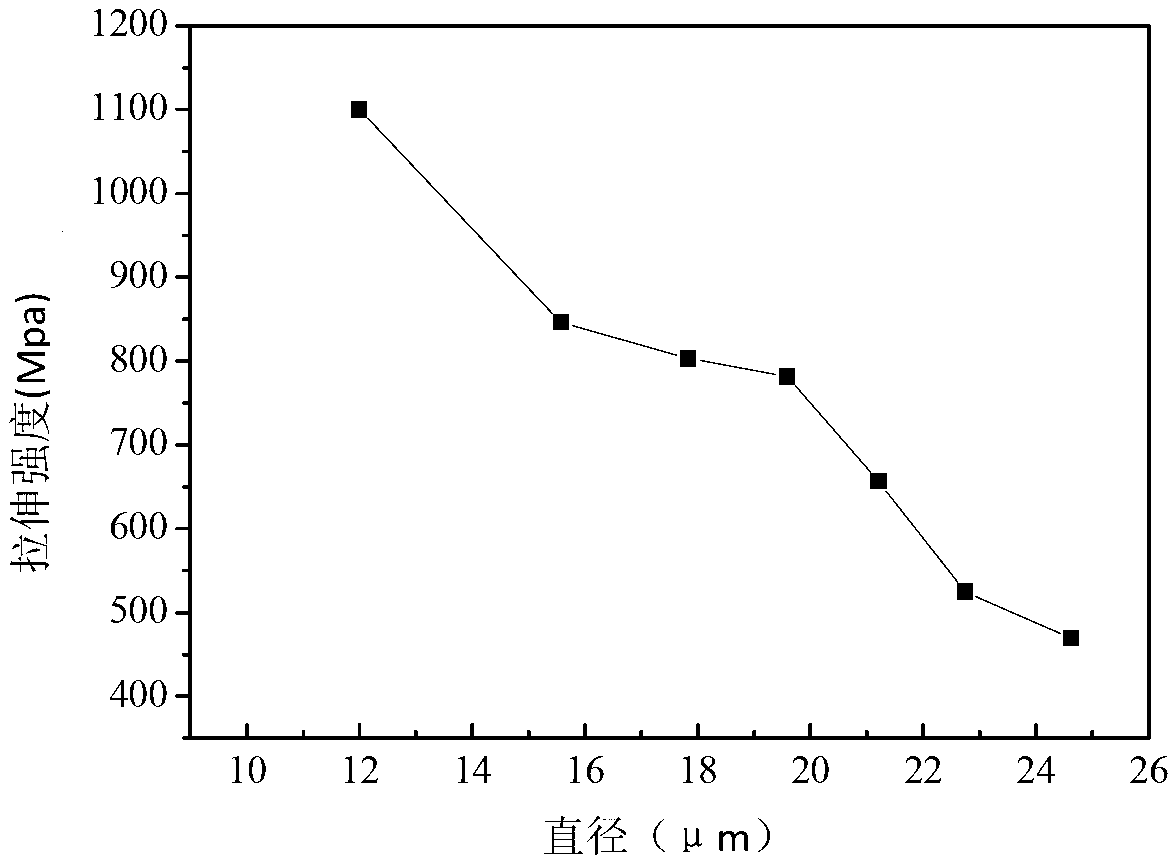

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com