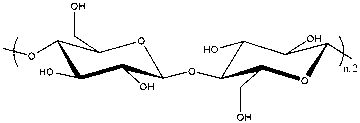

Microcrystalline cellulose and polycaprolactone reinforced starch-based full-biodegradable blending material and preparation method thereof

A technology of microcrystalline cellulose and polycaprolactone is applied in the field of starch-based fully biodegradable blend materials and their preparation, and can solve the problems of increased production cost of starch-based materials, limited application of starch-based materials, complicated preparation process, etc. , to achieve the effect of convenient preparation process, excellent mechanical properties and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 40 grams of microcrystalline cellulose and add it to 600 grams of glycerin under stirring to make it more evenly dispersed. Then put the dispersed mixed solution in an ultrasonic instrument for 30 minutes so that the microcrystalline cellulose is fully dispersed and uniform.

[0028] (2) Put the starch in a superfine pulverizer to refine it to 400 mesh.

[0029] (3) Weigh 857 grams of polycaprolactone and place it in a vacuum drying oven to fully dry it.

[0030] (4) Weigh 2000 grams of the refined starch obtained in step (2), put it in a high-speed mixer and mix it at high speed for 10 minutes, then add the microcrystalline cellulose and glycerin mixture dispersed in glycerin in step (1) to the high-speed mixer Mix in a mixer with the refined starch for 10 minutes at high speed, mix well, take out the mixture, seal it and let it stand for 1 day before use.

[0031] (5) Put the resting material obtained in step (4), the material in step (3) and 40 grams of s...

Embodiment 2

[0035] (1) Weigh 80 grams of microcrystalline cellulose, add 600 grams of glycerin under stirring to make the dispersion more uniform. Then put the dispersed mixed solution in an ultrasonic instrument for 30 minutes so that the microcrystalline cellulose is fully dispersed and uniform.

[0036] (2) Put the starch in a superfine pulverizer to refine it to 400 mesh.

[0037] (3) Weigh 500 grams of polycaprolactone and place it in a vacuum drying oven to fully dry it.

[0038] (4) Weigh 2000 grams of the refined starch obtained in step (2), put it in a high-speed mixer and mix it at high speed for 10 minutes, then add the microcrystalline cellulose and glycerin mixture dispersed in glycerin in step (1) to the high-speed mixer Mix in a mixer with the refined starch for 10 minutes at high speed, mix well, take out the mixture, seal it and let it stand for 1 day before use.

[0039] (5) Put the resting material obtained in step (4), the material in step (3) and 40 grams of silane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com