Method for removing trace hydrocarbon out of aromatic hydrocarbon by utilizing HMCM-41 type mesoporous molecular sieve

A technology of HMCM-41, mesoporous molecular sieve, applied in the direction of chemical change purification/separation, organic chemistry, etc., can solve the problems of weak acidity, limited application prospects, etc., to achieve the advantages of small environmental impact, simple process flow, and avoidance of landfill disposal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

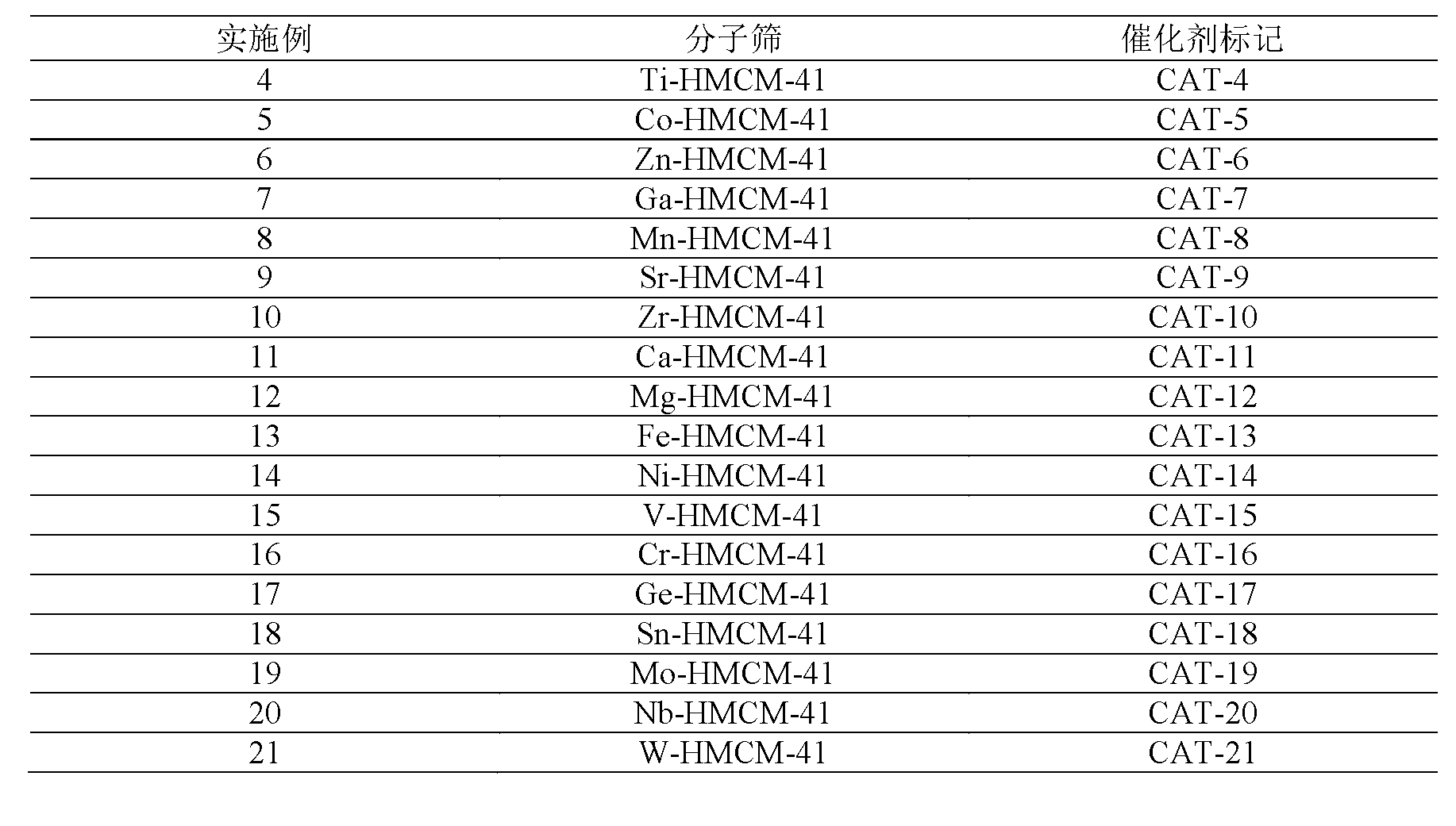

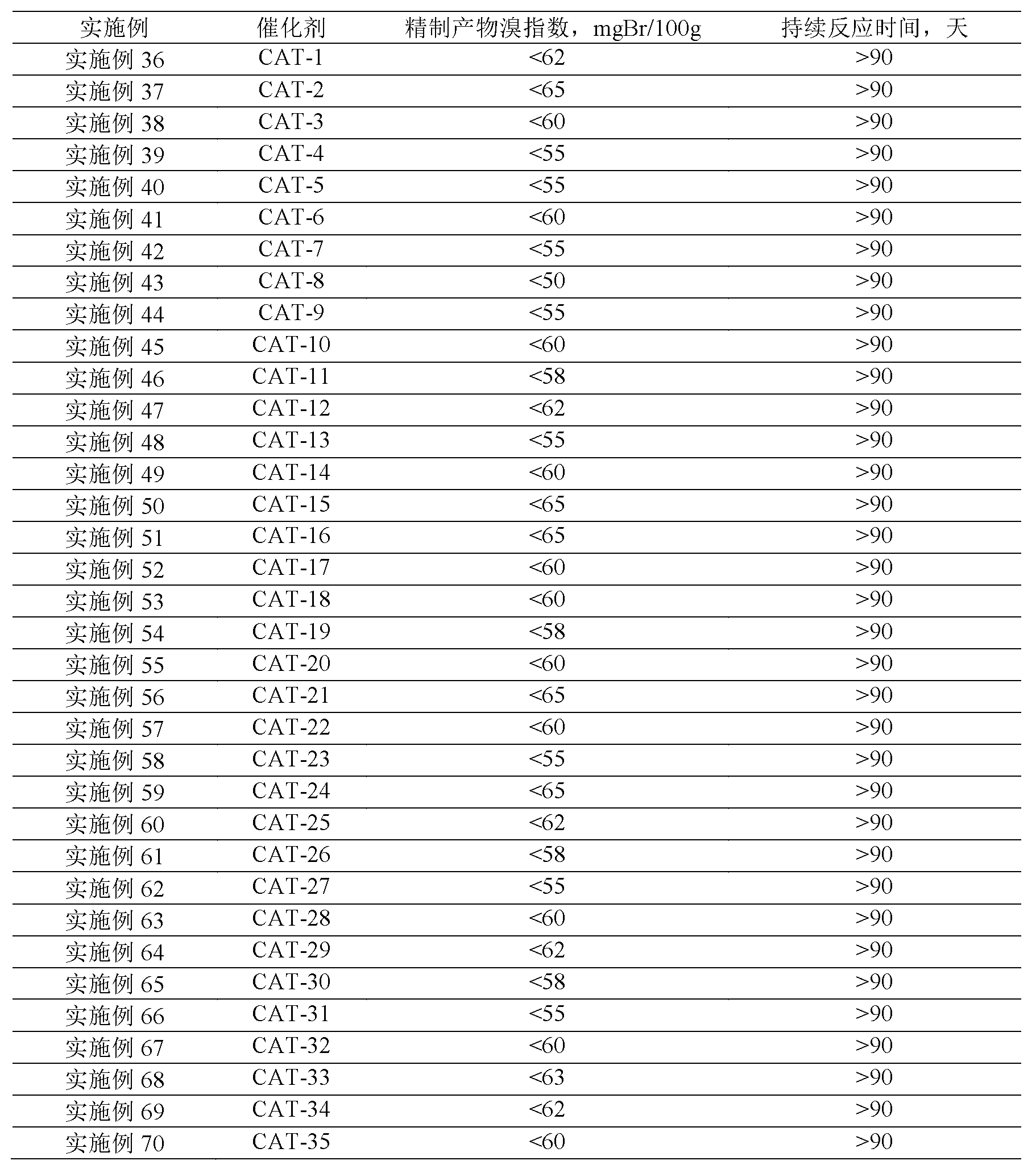

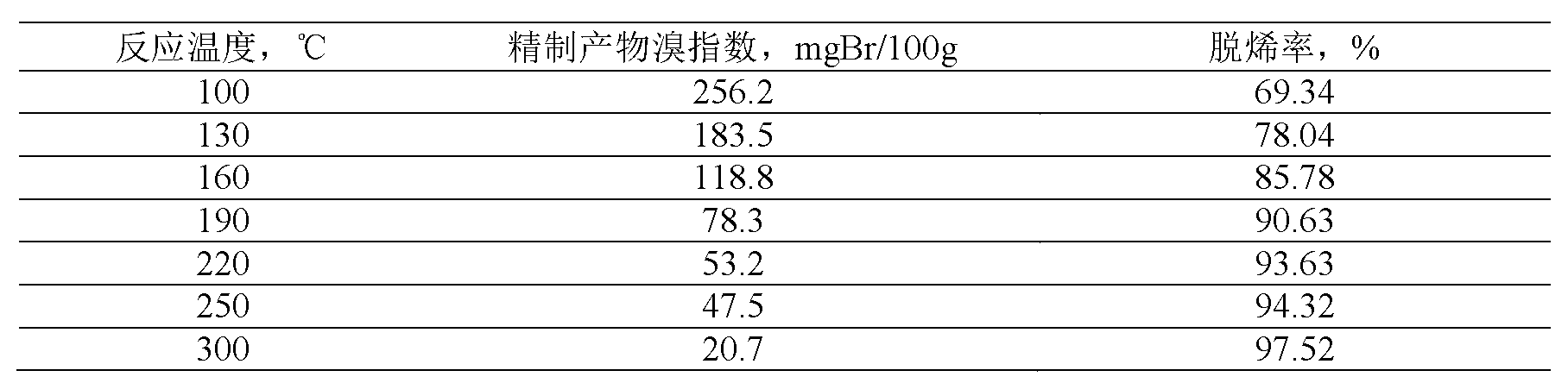

Examples

Embodiment 1

[0032] Synthesis of Al-HMCM-41 Mesoporous Molecular Sieve Catalyst

[0033] According to Al 2 o 3 : SiO 2 :CTMAB:NaOH:ETHA:H 2The raw material molar ratio of O is 1:10.0:1.4:2.4:8.67:140.0, weigh 4.86 grams of alumina monohydrate, and the calculated amount of silica sol, cetyltrimethylammonium bromide (CTMAB), hydroxide Sodium, ethanol (ETHA) and deionized water, stirred and mixed at 70°C for 5.0 hours, crystallized at 150°C and autogenous pressure for 24 hours, then filtered, washed with water, dried at 110°C for 3 hours, 550°C Roast for 5 hours to obtain the molecular sieve from which the template agent has been removed; 4 NO 3 , 1.0mol / L) ion-exchange the obtained molecular sieve at 85°C for 5 hours, then dry at 110°C for 3 hours and calcined at 550°C for 3 hours to obtain Al-HMCM-41 mesoporous molecular sieve catalyst powder; After the tablet is formed and ground, the catalyst is sieved with 20 to 40 mesh and recorded as CAT-1.

Embodiment 2

[0035] Synthesis of Cu-HMCM-41 Mesoporous Molecular Sieve Catalyst

[0036] According to Cu(NO 3 ) 2 : SiO 2 :CTMAB:NaOH:ETHA:H 2 The raw material molar ratio of O is 1:5.0:1.0:1.5:20.0:100.0, weigh 12.1 grams of copper nitrate, and the calculated amount of silica sol, cetyltrimethylammonium bromide (CTMAB), sodium hydroxide, Ethanol (ETHA) and distilled water were stirred and mixed at 60°C for 8.0 hours, crystallized at 180°C and autogenous pressure for 12 hours, then filtered, washed with water, dried at 100°C for 5 hours, and calcined at 500°C for 8 hours. Obtain the molecular sieve that removes the template agent; then according to the solid-liquid mass ratio of 1:30, use ammonium nitrate aqueous solution (NH 4 NO 3 , 0.7mol / L) the obtained molecular sieve was stirred at 90°C for 8 hours for ion exchange, then dried at 100°C for 3 hours and calcined at 500°C for 3 hours to obtain Cu-HMCM-41 mesoporous molecular sieve catalyst powder; After the tablet is formed and gr...

Embodiment 3

[0038] Synthesis of B-HMCM-41 Mesoporous Molecular Sieve Catalyst

[0039] According to H 3 BO 3 : SiO 2 :CTMAB:NaOH:H 2 The raw material molar ratio of O is 1:50.0:2.5:4.0:240.0, weigh 3.1 grams of boric acid, and the calculated amount of silica sol, cetyltrimethylammonium bromide (CTMAB), sodium hydroxide and deionized water , they were stirred and mixed at 90°C for 3.0 hours, crystallized at 120°C and autogenous pressure for 48 hours, then filtered, washed with water, dried at 120°C for 5 hours, and calcined at 600°C for 3 hours to obtain template-removing Molecular sieve; then according to the solid-liquid mass ratio of 1:20, ammonium nitrate aqueous solution (NH 4 NO 3 , 1.2mol / L) the obtained molecular sieve was stirred at 85°C for 8 hours for ion exchange, then dried at 120°C for 3 hours and calcined at 600°C for 3 hours to obtain B-HMCM-41 mesoporous molecular sieve catalyst powder; After the tablet is formed and ground, the catalyst is sieved with 20 to 40 mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bromine index | aaaaa | aaaaa |

| Bromine index | aaaaa | aaaaa |

| Bromine index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com