Method for preparing PZN based multi-element composite perovskite type piezoelectric ceramics

A technology of composite perovskite and piezoelectric ceramics, which is applied in the field of preparation of multi-component composite perovskite piezoelectric ceramics, can solve the problem that the pyrochlore phase cannot be effectively eliminated and serious pyrochlore phases can be eliminated, and the pyrochlore phase can be suppressed. The formation of stone phase, high sintering quality, and the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

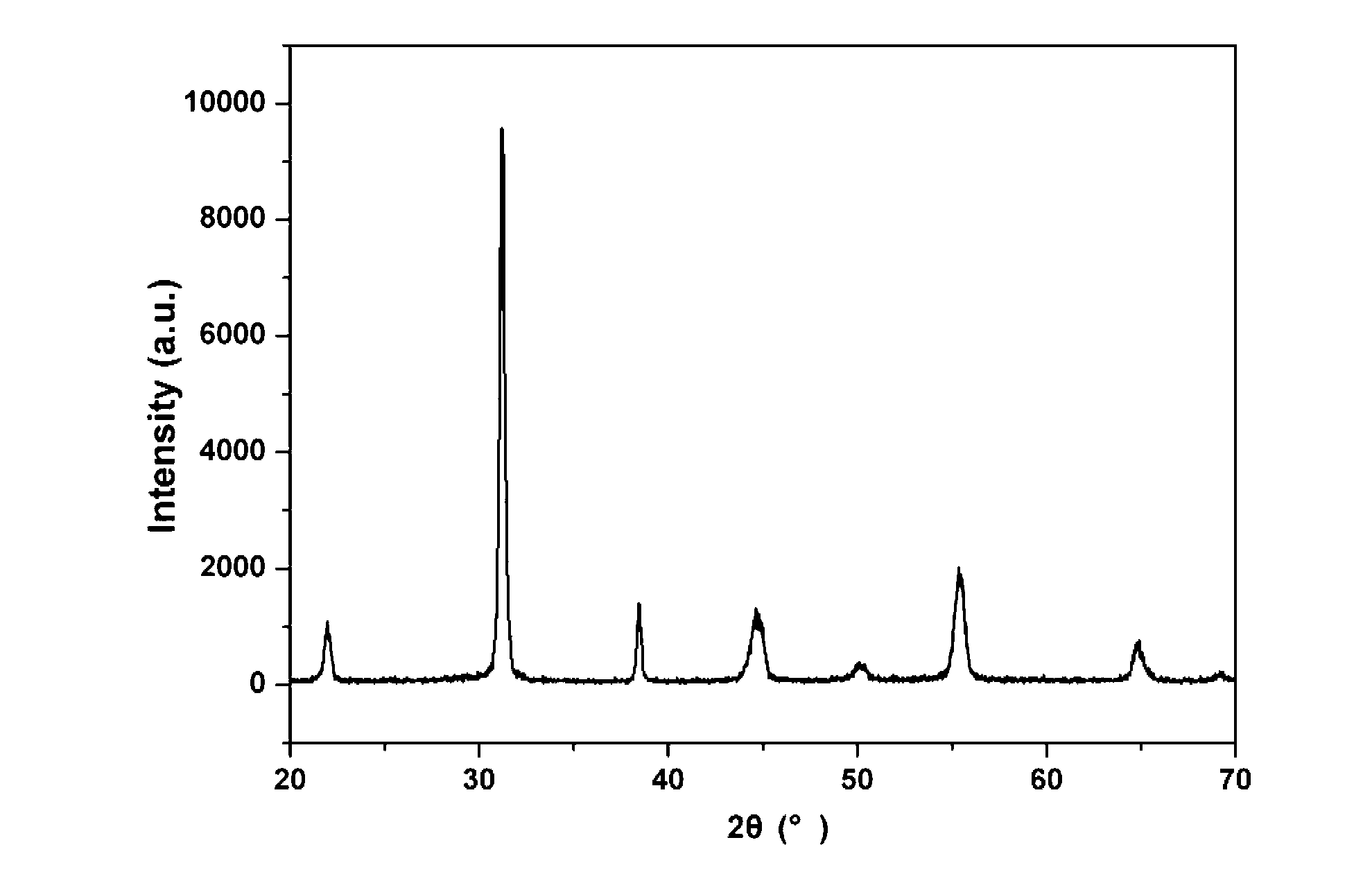

[0016] Example 1 Preparation of 0.30PYN-0.45PZN-0.25PT

[0017] According to the chemical formula, the dosage is 0.01mol. Weigh Yb separately 2 o 3 , ZnO, Nb 2 o 5 Each 0.2956g, 0.1221g, 0.5981g, put it in an agate mortar, add absolute ethanol and grind it manually for 2h; dry it, press it under 10Mpa; then put it in a covered crucible for calcination, and react at 1000℃ 4h; Weigh the obtained YZN mixture and PbO (excess 1%), TiO 2 2.2408g and 0.1945g each, in an agate mortar, add absolute ethanol and manually grind for 2h; dry, press into tablets at 10Mpa; react at 850°C for 5h; obtain 0.30PYN-0.45PZN-0.25PT ceramic powder.

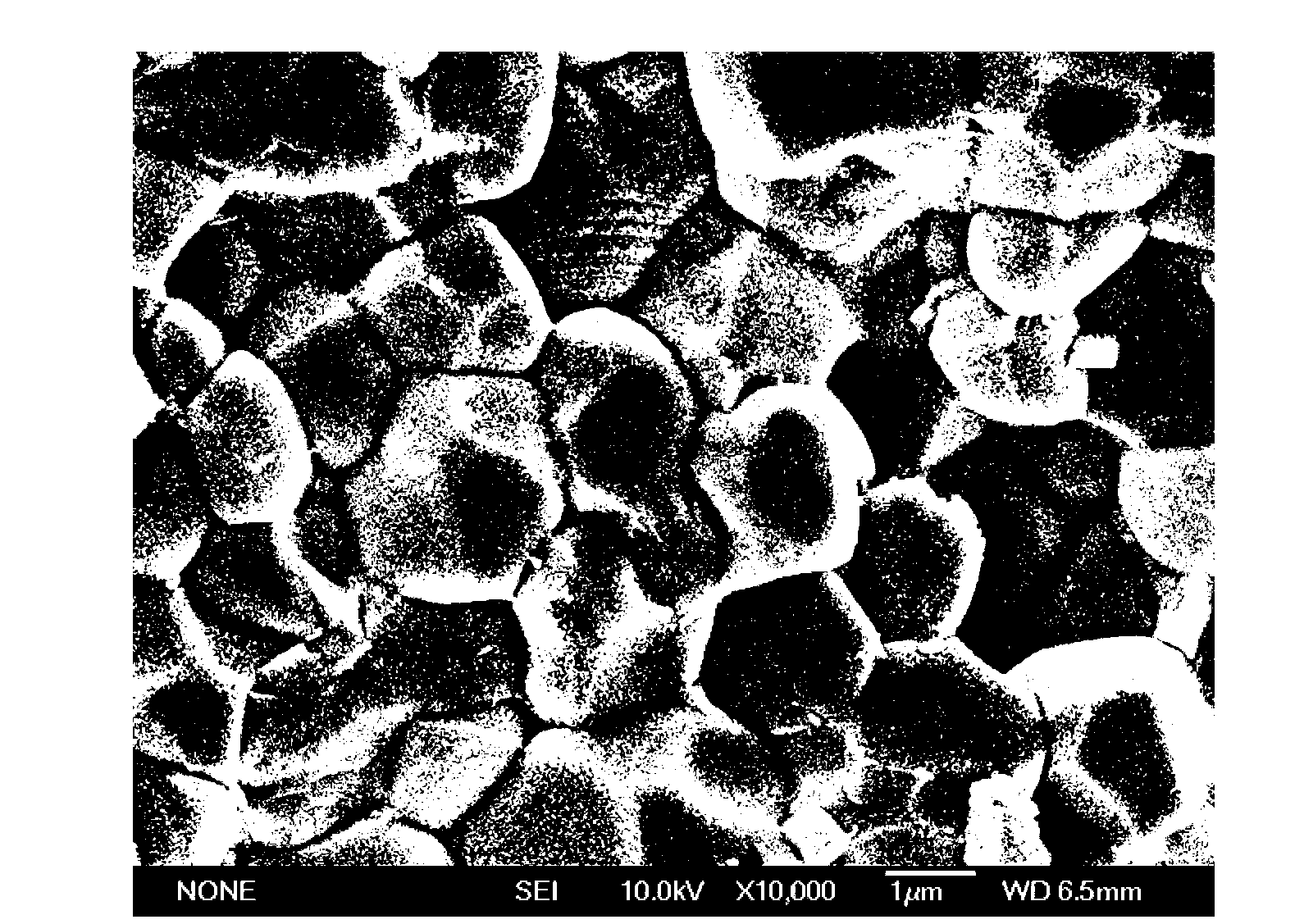

[0018] Put the obtained ceramic powder in an agate mortar, add absolute ethanol and manually grind for 2 hours, add an appropriate amount of 5wt% PVA, mix evenly; dry, press into a disc with a diameter of 10mm and a thickness of 1mm at 14Mpa; Plastic discharge at 500°C for 2 hours; then cold isostatic pressing at 200Mpa for 2 minutes; sintering met...

Embodiment 2

[0019] Example 2 Preparation of 0.28PYN-0.45PZN-0.27PT

[0020] According to the chemical formula, the dosage is 0.01mol. Weigh Yb separately 2 o 3 , ZnO, Nb 2 o 5 0.2758g, 0.1221g, 0.5848g each, put them in an agate mortar, add absolute ethanol and grind them by hand for 2h; dry, press into tablets at 10Mpa; then place them in a covered crucible for calcination, and react at 1000°C 4h; Weigh the obtained YZN mixture and PbO (excess 1%), TiO 2 2.277g and 0.2089g respectively; other steps are as in Example 1.

Embodiment 3

[0021] Example 3 Preparation of 0.27PYN-0.45PZN-0.28PT

[0022] According to the chemical formula, the dosage is 0.01mol. Weigh Yb separately 2 o 3 , ZnO, Nb 2 o 5 Each 0.266g, 0.1221g, 0.5781g, put it in an agate mortar, add absolute ethanol and grind it manually for 2h; dry it, press it under 10Mpa; then put it in a covered crucible for calcination, and react at 1000℃ 4h; Weigh the obtained YZN mixture and PbO (excess 1%), TiO 2 Each 2.1024g, 0.2045g; other steps are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com