Polyethylene terephthalate (PET)-based composite material capable of sensing stress variation and preparation method thereof

A composite material and stress change technology, which is applied in the field of PET-based composite materials capable of sensing stress changes and its preparation, can solve the problems of high sensitivity of force-electricity coupling effect, little influence of humidity, strong reversibility, etc., and achieve good deformation Coordinating performance, little influence of humidity, strong reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

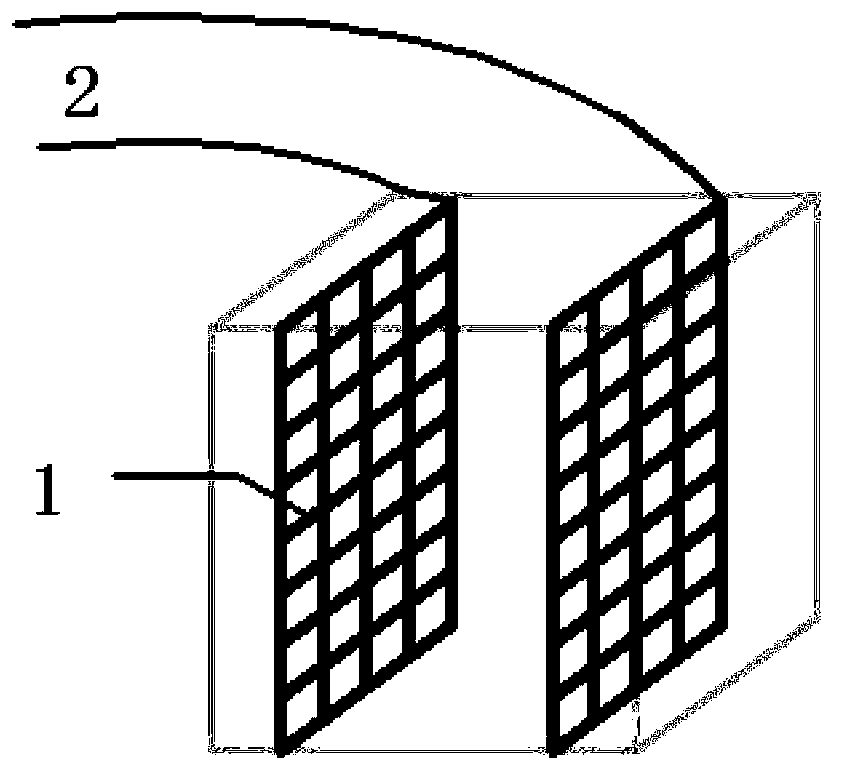

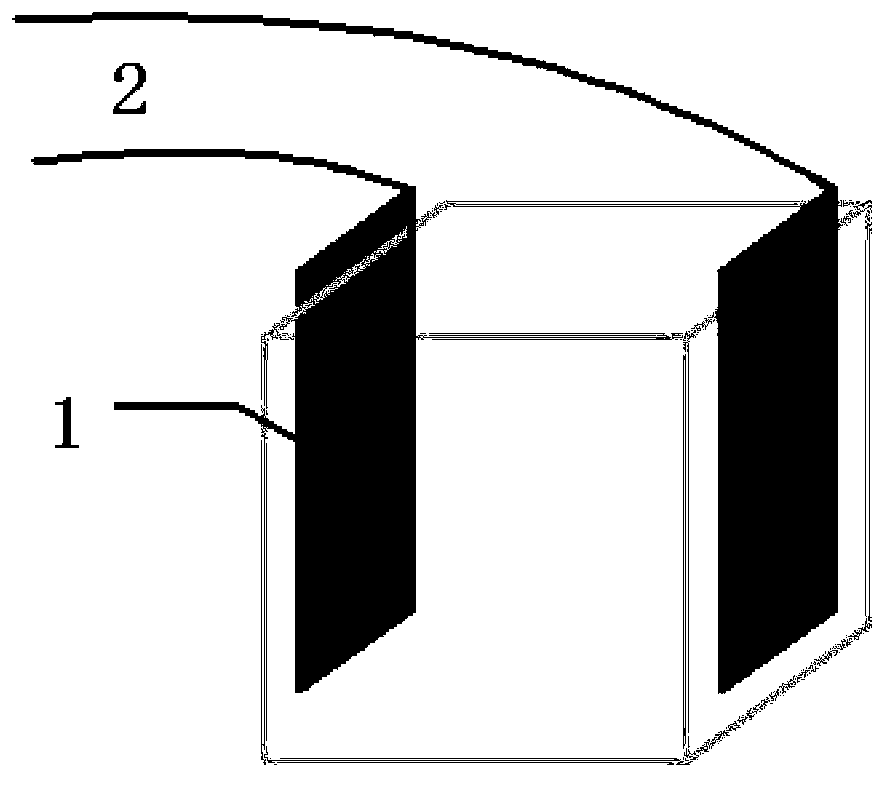

Image

Examples

Embodiment 1

[0060] Materials: 2.5 parts of waste PET, 7.5 parts of aggregate, 0.05 part of talcum powder, 0.5 part of fly ash, and 1.2 parts of graphite. The gradation of the aggregate is shown in Table 3.

[0061] Among them: graphite is medium carbon flake graphite with carbon content ≥ 94%, with an average particle size of 11 μm to 13 μm;

[0062] Nickel powder is gray black dendritic nickel powder with a nickel content of 99.9%, particle size ≤13μm;

[0063] Fly ash is Class I fly ash;

[0064] Talc powder is SL plastic grade talc powder.

[0065] Table 3, embodiment 1 use the gradation of aggregate

[0066]

[0067] Preparation: Dry mix waste PET, aggregate, talcum powder, and fly ash evenly, place in an oven and heat at 260°C-285°C for 150min-180min; add graphite one by one, mix until uniform, and statically press to form, The static pressure is controlled at 15MPa; together with the test mold, put it into the sand bath, keep it healthy for 24 hours at 80°C to 160°C, and demol...

Embodiment 2

[0070] The difference between this example and Example 1 is that the aggregate gradation is adjusted as follows, the addition of 0.6-0.3, 0.3-0.15, and 0.15-0.075 third-grade materials is added, and the gradation of the aggregate is finer. As in Table 4.

[0071] Table 4, embodiment 2 use the gradation of aggregate

[0072]

[0073] Results: The compressive strength of the material prepared in this example is 28.73MPa, which is lower than that of the material prepared in Example 1; its resistivity is 48.74Ω·m, which is close to that of Example 1, which also shows the degree of gradation Fine-tuning has little effect on resistivity;

Embodiment 3

[0075] The difference between this example and Example 1 is that the aggregate gradation is adjusted as follows, the addition of 9.3-4.75, 4.75-2.36, and 2.36-1.18 third-grade materials is added, and the gradation of the aggregate is coarse. As in Table 5.

[0076] Table 5, embodiment 3 use the gradation of aggregate

[0077]

[0078] Results: The compressive strength of the material prepared in this example is 29.54MPa, which is lower than that of the material prepared in Example 1; its resistivity is 43.27Ω·m, which is close to that of Example 1, which also shows the degree of gradation Trimming has little effect on resistivity.

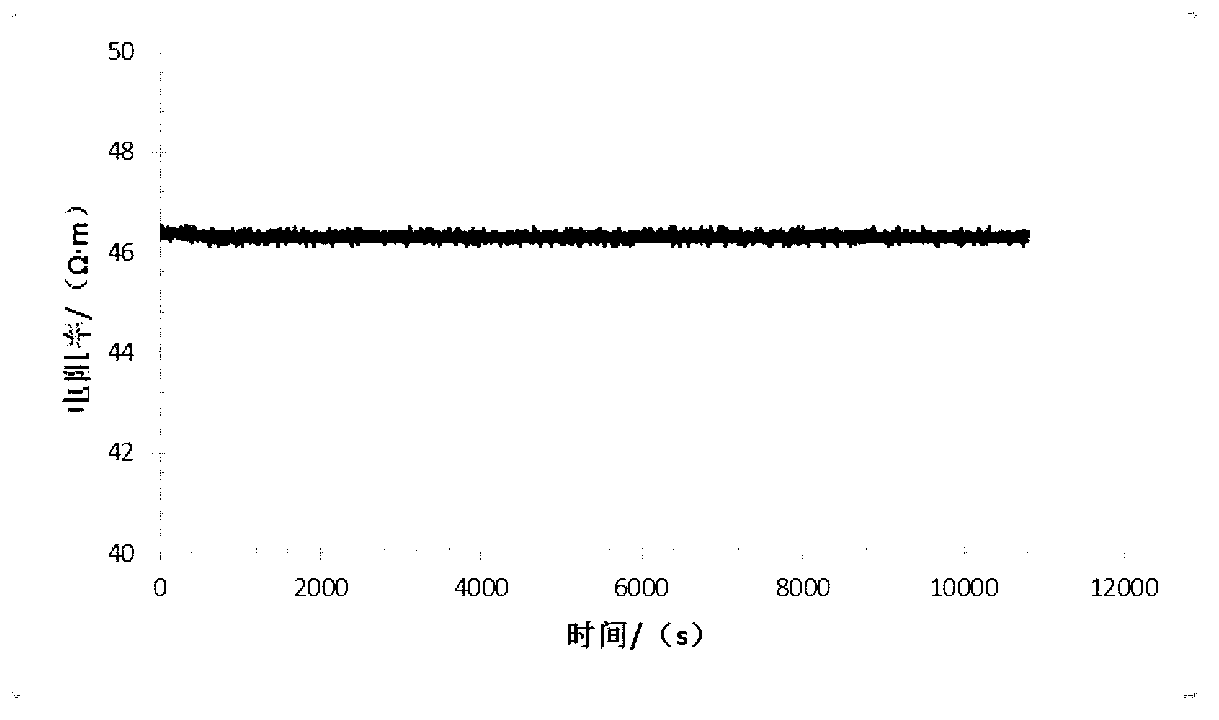

[0079] Use the test piece prepared in this embodiment to carry out the force-electric coupling test, and the loading method is as follows:

[0080] Loading method 1: The maximum load is 1.43MPa, the minimum load is 0.18MPa, the frequency of cyclic load is 0.073Hz, the frequency of resistance data collection is 2.0Hz, the same load is used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com