Composite material plate, preparation method and use of composite material plate

A composite material board and skin layer technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve the effects of low energy consumption, low pollution, and low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

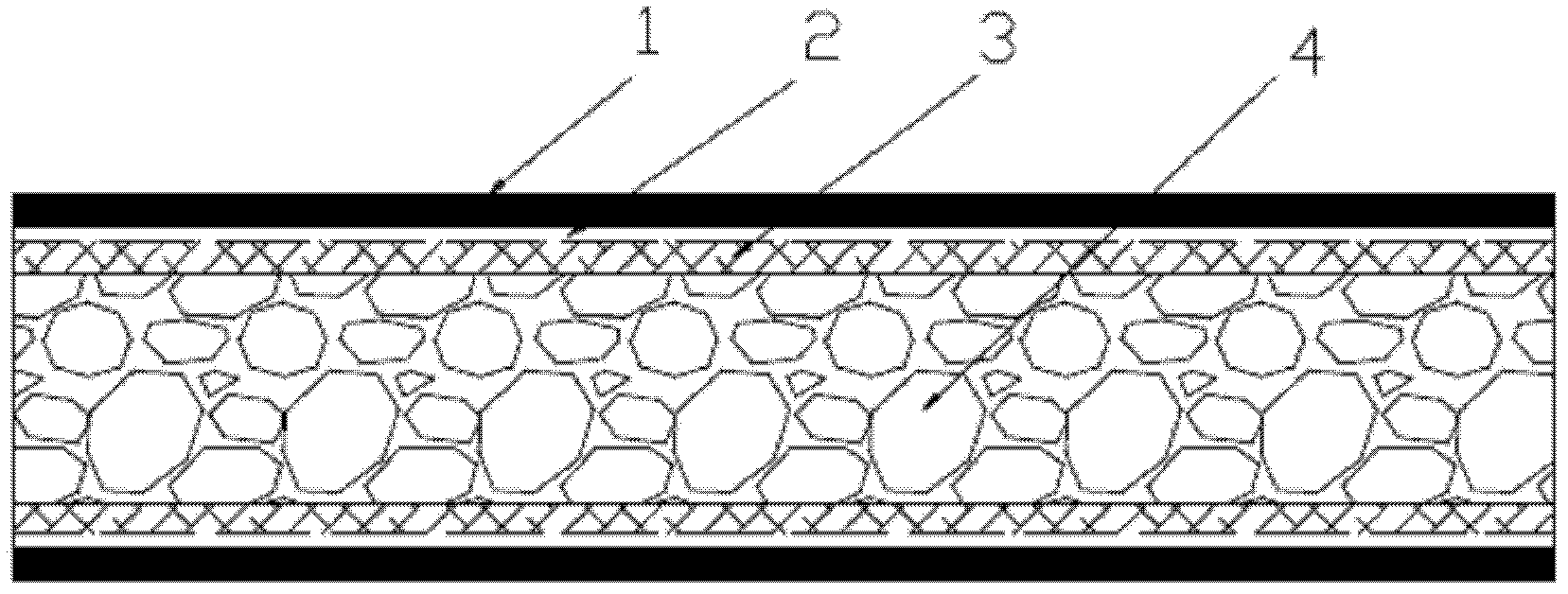

[0053] (1) Lay 5 layers of glass fiber plain weave cloth on the mold of VARTM with 0 / 90 ° cross, then lay a layer of 30mm thick Balsa wood core material to form sandwich layer 4; Lay 5 layers of glass fiber plain weave cloth again, After laying, the fabric is sewn closed along the perimeter. Finally, lay the guide fabric (such as plastic film guide cloth) and vacuum film, seal the joint between the mold and the vacuum film, vacuumize until the vacuum degree reaches 0.1Mpa, and then introduce the epoxy resin JL-236 mixture containing curing agent and additives (Changshu Jiafa Co., Ltd.), make the epoxy resin glue completely impregnate the fiber layer to form a skin layer 3, finally fill the inside of the mold, and form a 0.5mm thick rubber-rich layer 2 outside the skin layer to control the fiber content of the skin layer 50%, heated to 80°C for curing and molding.

[0054] (2) Put the solidified sandwich structure plate in step (1) into the middle of the polydicyclopentadiene ...

Embodiment 2

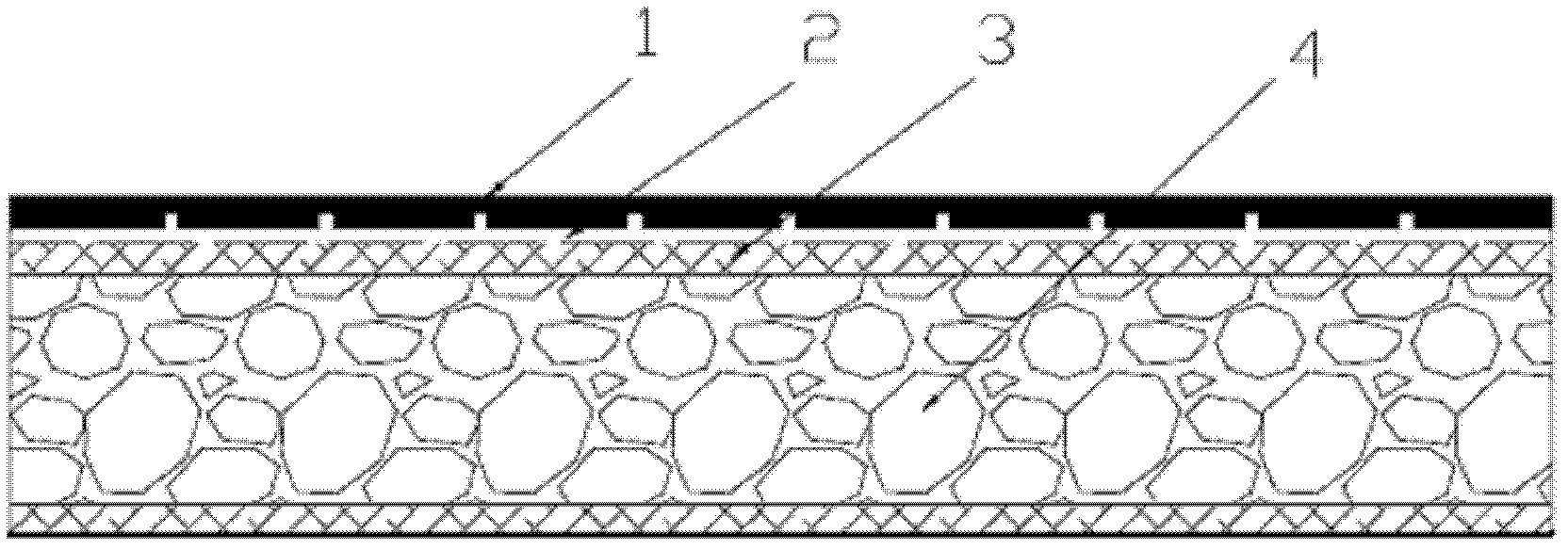

[0056] Mix polydicyclopentadiene reaction raw material A and reaction raw material B components uniformly in a ratio of 1:1, inject them into the polydicyclopentadiene shell mold through the injection head, and control the mold temperature at 80°C to 85°C. After the curing is completed, take out the polydicyclopentadiene shell 1. The thickness of the shell is 7 mm. There is a concave structure on the inner wall of the shell. The concave structure is a plurality of evenly distributed groove-like structures. The shell is placed on a vacuum-assisted resin transfer molding mold; 5 layers of glass fiber plain weave are cross-laid on the shell at 0 / 90°, and then a layer of 30mm thick lightweight paulownia wood core material is laid to form a sandwich Layer 4: Lay 5 layers of glass fiber plain weave cloth again, and glue and seal the fabric along the periphery after laying. Finally, lay the diversion fabric and vacuum film on the glass fiber plain cloth, seal the joint between the mo...

Embodiment 3

[0058] (1) Using a three-dimensional weaving method to weave a strip-shaped carbon fiber fabric with an "I"-shaped cross section as the reinforcing rib 5, and the upper and lower "one"-shaped transverse structures are respectively composed of two carbon fiber plain weave fabrics.

[0059] (2) Lay 6 layers of carbon fiber plain weave cloth on the RTM mold at 0 / 90° cross-laying. At the position where the reinforcing ribs are laid, only the top two layers and the bottom two layers of carbon fiber plain weave are laid on the fiber reinforced layer, and then the reinforcing ribs are laid. Place the carbon fiber plain weave cloth with "work" type reinforcement at the position, and use it as a part of the skin layer, and then lay a 30mm thick paulownia wood core material in the middle of the reinforcement to form the sandwich layer 4; lay 6 layers of carbon fiber plain weave again, and Lay the overlapping carbon fiber plain cloth of the other transverse plane of the "I" type reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com