Alpha-lactalbumin hydrolysate and preparation method and application thereof

A technology of lactalbumin hydrolysis and lactalbumin is applied in the field of alpha-lactalbumin hydrolyzate and its preparation, and achieves the effects of rapid capacity, increased drowsiness and satisfying nutritional needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the enzyme reactor, use pure water to prepare α-lactalbumin into a solution with an α-lactalbumin concentration of 50mg / ml, adjust the solution to 7.0 with 1M NaOH, and add to the solution at a temperature of 40°C Flavor protease that accounts for 1% of the amount of α-lactalbumin in the solution is hydrolyzed for about 1.5 hours until the degree of hydrolysis reaches 7%, and the hydrolysis is terminated by inactivating the enzyme at 100° C. for 5 minutes to obtain α-lactalbumin hydrolysis solution. The solution was concentrated to a concentration of 45%, and then freeze-dried to obtain the α-lactalbumin hydrolyzed powder of this example.

[0031] 43kg of isolated whey protein, 4kg of dietary fiber, 9kg of medium-chain fatty acids, 2kg of vitamins and minerals are mixed in deionized water to prepare a solution of 240mg / ml, and the prepared solution is homogeneous (temperature 55°C, first-grade Homogeneous pressure 30Mpa, secondary homogeneous pressure 10Mpa), after h...

Embodiment 2

[0036] In the enzyme reactor, use pure water to prepare α-lactalbumin into a solution with a concentration of α-lactalbumin of 20mg / ml, adjust the solution to 8.0 with 1M NaOH, and add to the solution at a temperature of 35°C Flavor protease, which accounts for 3% of the amount of α-lactalbumin in the solution, is hydrolyzed for about 3.0 hours until the degree of hydrolysis reaches 7%, and the hydrolysis is terminated by inactivating the enzyme at 90°C for 3 minutes to obtain α-lactalbumin hydrolysis solution. The solution was concentrated to a concentration of 45%, and then freeze-dried to obtain the α-lactalbumin hydrolyzed powder of this embodiment. The hydrolyzed powder has good flavor without unacceptable bitterness.

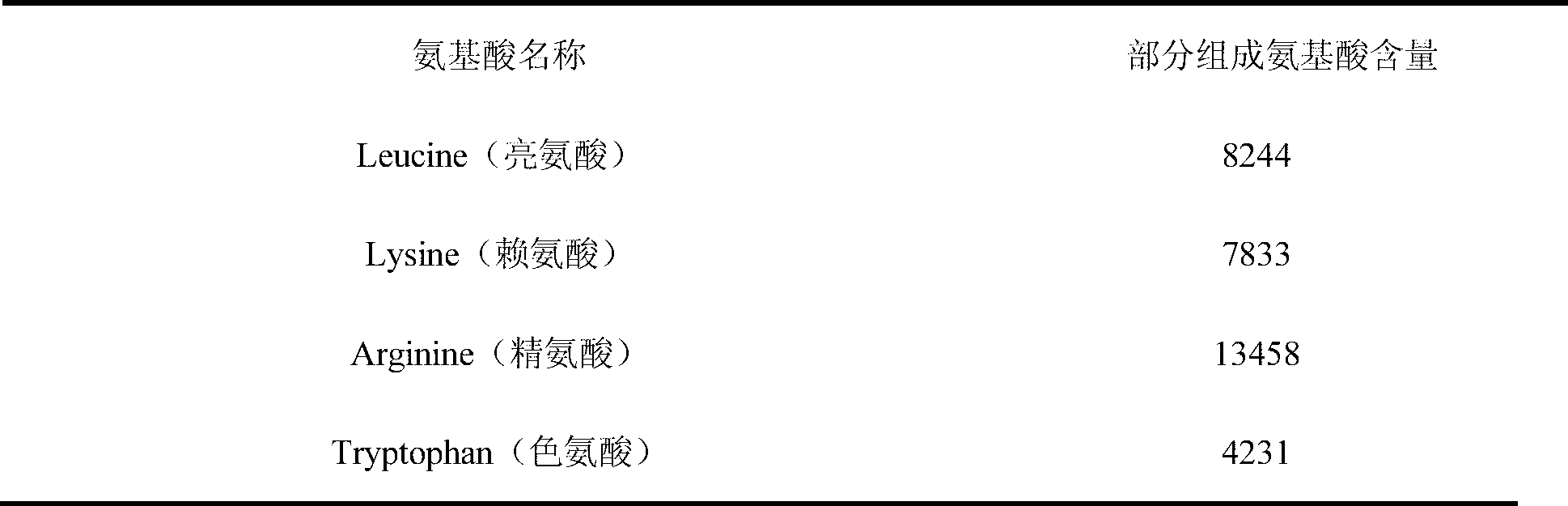

[0037] The amino acid content of the hydrolyzate obtained in this embodiment is shown in Table 2:

[0038] Table 2. Analysis of amino acid content in some components (mg / 100g)

[0039]

Embodiment 3

[0041] In the enzyme reactor, use pure water to prepare α-lactalbumin into a solution with a concentration of α-lactalbumin of 100 mg / ml, adjust the solution to 5.0 with 1M HCl, and add 0.5% of the amount of α-lactalbumin in the solution was hydrolyzed with flavor protease for about 0.5 hours until the degree of hydrolysis reached 7%, and the hydrolysis was terminated by inactivating the enzyme for 4 minutes at 95°C to obtain α-lactalbumin hydrolysis solution. The solution was concentrated to a concentration of 45%, and then freeze-dried to obtain the α-lactalbumin hydrolyzed powder of this embodiment. The hydrolyzed powder has good flavor without unacceptable bitterness.

[0042] The amino acid content of the hydrolyzate obtained in this embodiment is shown in Table 3:

[0043] Table 3. Analysis of amino acid content in some components (mg / 100g)

[0044]

[0045] The obtained hydrolyzate molecular weight distribution of embodiment 3 is as follows table 4:

[0046] Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com