Ethylene copolymer with improved elasticity and processibility

A technology of ethylene copolymer and olefin comonomer, which is applied in transportation, packaging, and thin material processing, etc., and can solve the problems of reduced impact resistance and product hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

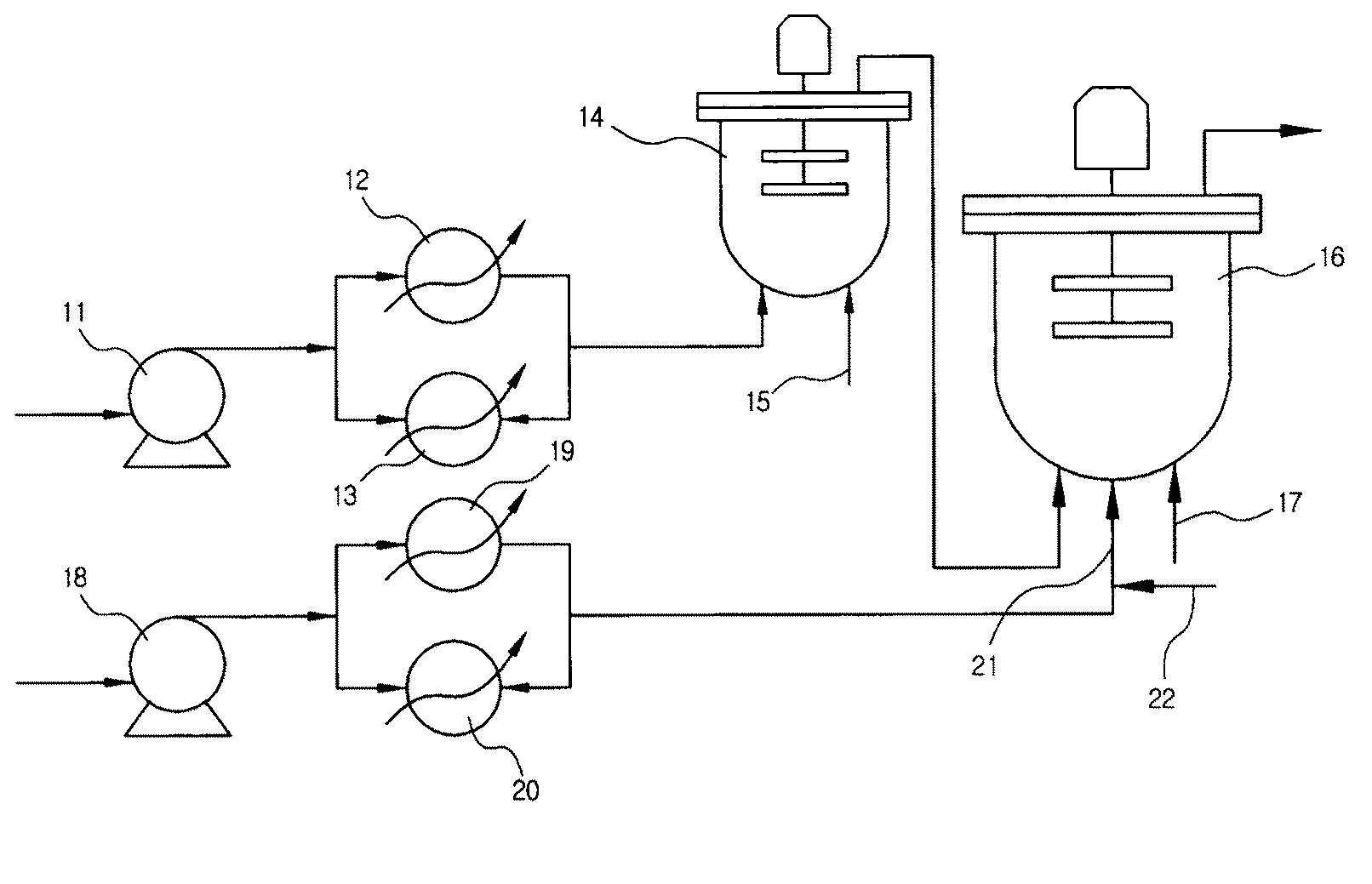

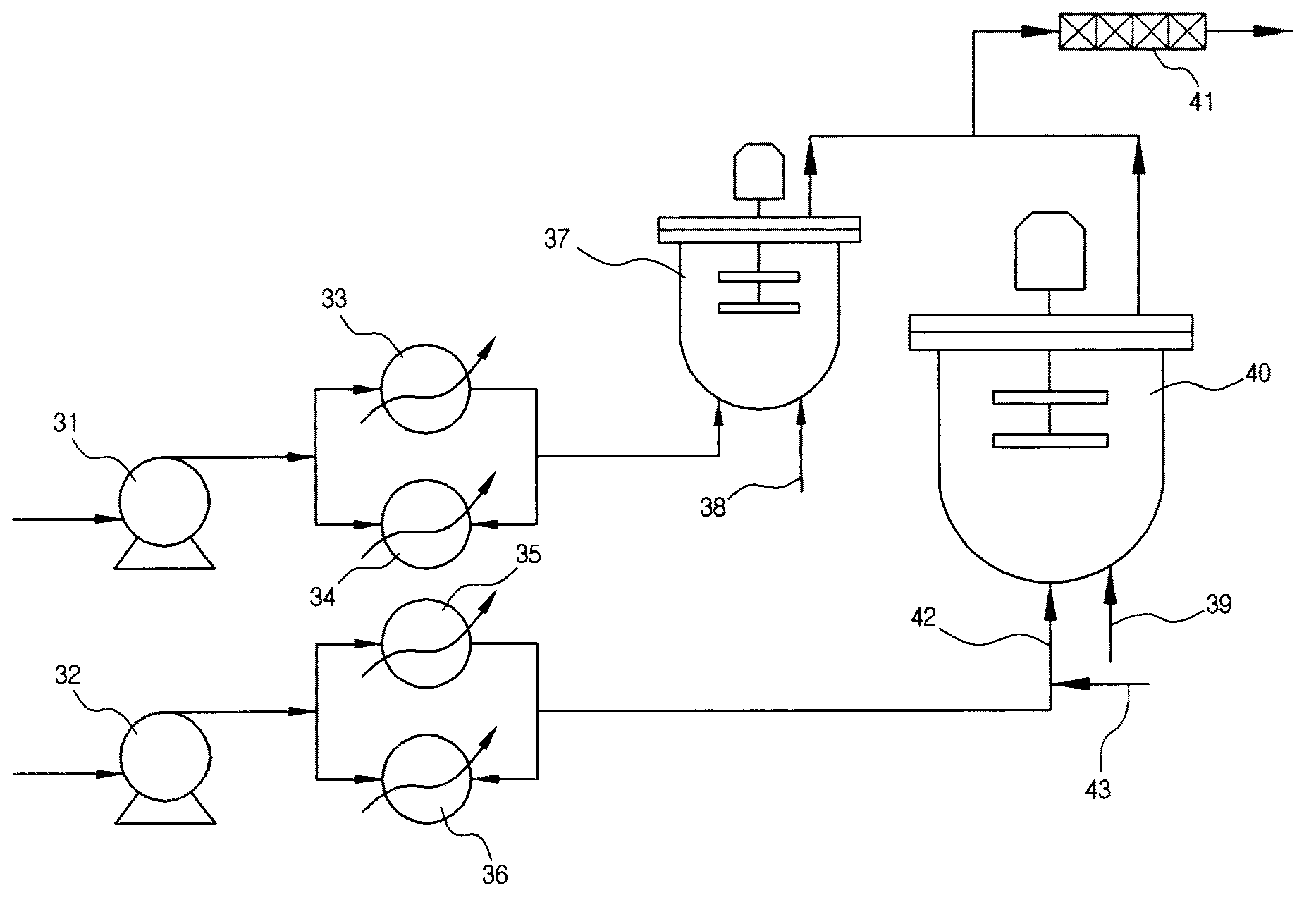

Method used

Image

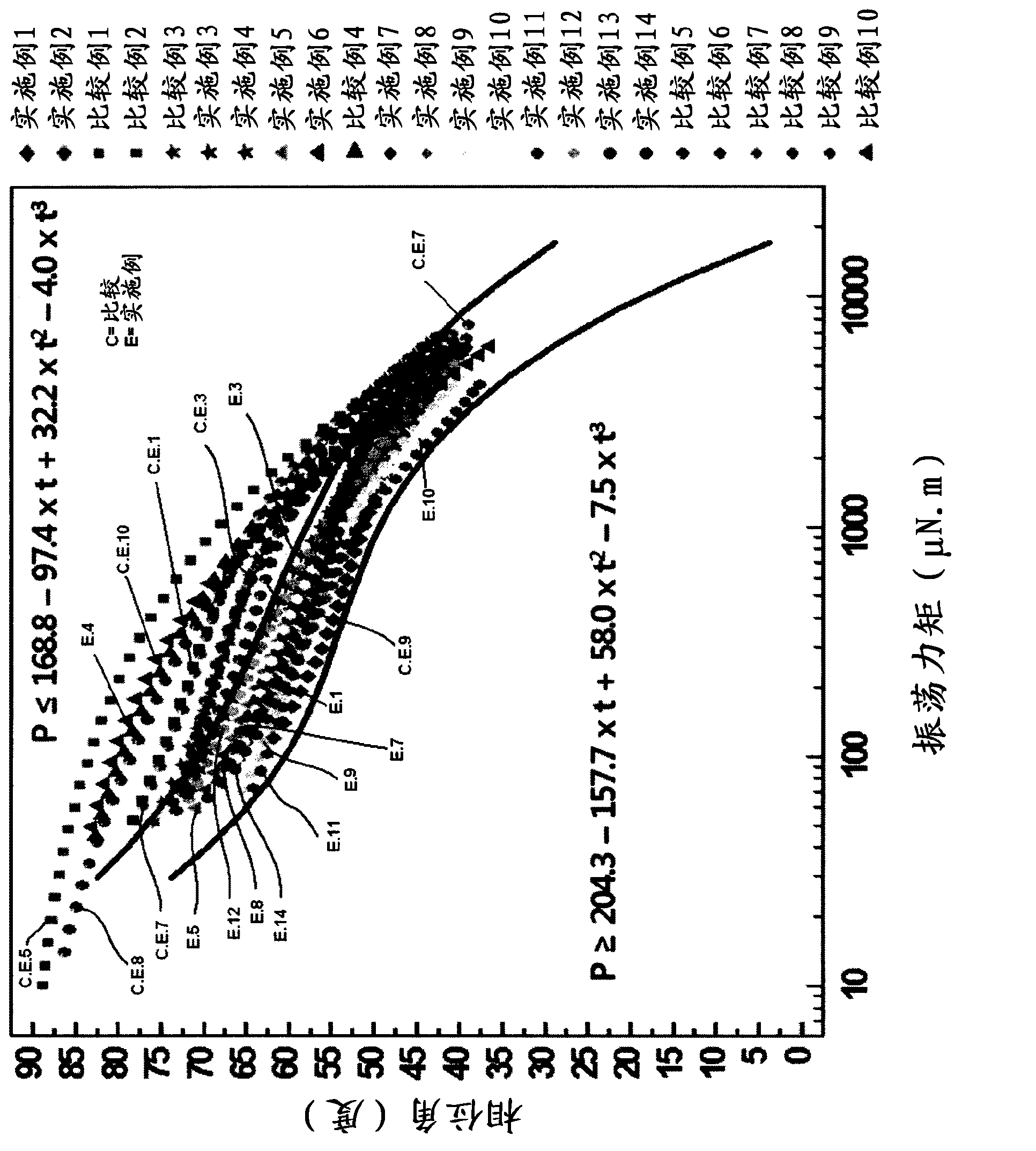

Examples

preparation Embodiment 1

[0162] Synthesis of bis(2-phenylphenoxy)(pentamethylcyclopentadienyl)titanium(IV) chloride

[0163] 2-Phenylphenol (1.72 g, 10.1 mmol, Aldrich 99%) was added to a dry flask and dissolved in 40 mL of toluene, then cooled to 0° C. while stirring well. The resulting mixture was slowly added dropwise to n-butyllithium (4.8 mL, 2.5M in hexane, Aldrich). After completion of the dropwise addition, the temperature of the resulting mixture was maintained for 1 hour and then raised to room temperature, followed by stirring for 12 hours. The temperature of the resulting mixture was lowered to 0° C., and thereto was slowly added dropwise pentamethylcyclopentadienyltitanium trichloride (1.64 g, 5.5 mmol) dissolved in 10 mL of toluene. After the dropwise addition was completed, the temperature of the resulting mixture was maintained for 1 hour and then raised to room temperature, followed by stirring for 1 hour. The reaction was carried out for 12 hours after raising the temperature of ...

Embodiment 1 to 6

[0167] Bis(2-phenylphenoxy)(pentamethylcyclopentadienyl)titanium(IV) chloride synthesized in Preparation Example 1 was used as a single active site in the second-stage reactors connected in series point catalysts, ie, transition metal catalysts. The amount of catalyst used is shown in Table 1. Ti stands for a single active site catalyst, and as a cocatalyst Al stands for triisobutylaluminum and B stands for triphenylmethyliniumtetrakispentafluorophenyl borate. Each catalyst was dissolved in xylene at a concentration of 0.2 g / L, 5.0 g / L or 1.5 g / L, respectively, and then injected. The synthesis was carried out with an ethylene feed ratio of 4:6 and utilized either 1-octene or 1-butene as comonomer for each reactor. However, when the conversion rate is low in order to adjust the polymer density and molecular weight in the first-stage reactor, the amount of ethylene fed into the second-stage reactor is based on the amount of unreacted ethylene flowing into the second-stage reac...

Embodiment 7 to 14

[0172] Bis(2-phenylphenoxy)(pentamethylcyclopentadienyl)titanium(IV) chloride synthesized in Preparation Example 1 was used as a single active site in the second-stage reactors connected in series Point catalyst. The amount of catalyst used is shown in Table 2. Ti stands for a single active site catalyst, and as a cocatalyst Al stands for triisobutylaluminum and B stands for tritylaluminum tetrapentafluorophenylborate. Each catalyst was dissolved in xylene at a concentration of 0.2 g / L, 5.0 g / L or 1.5 g / L, respectively. The synthesis was carried out at an ethylene feed ratio of 3.5:6.5 to 4.5:5.5 and utilized 1-octene or 1-butene as comonomer per reactor. However, when the conversion rate is low in order to adjust the polymer density and molecular weight in the first-stage reactor, the amount of ethylene fed into the second-stage reactor is based on the amount of unreacted ethylene flowing into the second-stage reactor Sure. The conversion rate in each reactor can be deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com