Technology for smelting ER70S-6 welding wire steel through utilizing vanadium-containing molten iron

A technology of ER70S-6 and welding wire steel, which is applied in the field of metallurgy, can solve the problems of low strength of welding wire steel, poor spinning effect, and low weld strength, and achieve the effects of increasing strength, improving toughness and reducing sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

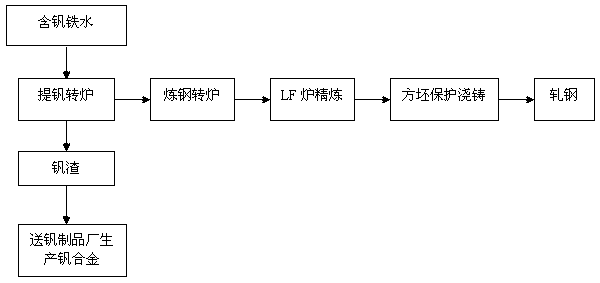

Image

Examples

Embodiment 1

[0016] The molten iron after vanadium extraction, C: 3.78, V: 0.031%, S: 0.038%, Cr+Ni+Cu: 0.042%, is blended into the steelmaking converter, and the end point of blowing is C: 0.05%, P: 0.012%, S : 0.028%, which meets the requirements of tapping. During the tapping process, 0.3kg / ton of silicon-aluminum-barium deoxidizer, 358kg of lime, 142kg of refining slag, 0.5kg / ton of ferrosilicon powder, and 0.008% of remaining vanadium, Cr +Ni+Cu: 0.017%; 0.9kg / ton of ferrosilicon powder is added to LF furnace refining, 0.9kg / t of ferrosilicon powder is added to LF furnace refining to reduce vanadium in slag, and the vanadium content in steel is increased by 0.003%, and carbon powder and ferrosilicon are used and low-carbon ferromanganese to fine-tune other components. After meeting the requirements of the finished product, soft blow for 12 minutes, hang and cast to protect the casting, and the properties of the billet after rolling meet the requirements of the national standard. The c...

Embodiment 2

[0018] The molten iron after vanadium extraction, C: 3.67, V: 0.042%, S: 0.035%, Cr+Ni+Cu: 0.046%, is blended into the steelmaking converter, and the end point of blowing is C: 0.04%, P: 0.010%, S : 0.021%, which meets the requirements of tapping. During the tapping process, 0.4kg / ton of silicon aluminum barium deoxidizer is added, 398kg of lime, 145kg of refining slag, 0.5kg / ton of ferrosilicon powder, 0.005% of remaining vanadium, Cr +Ni+Cu: 0.014%; 0.7kg / ton of ferrosilicon powder is added to LF furnace refining, 0.9kg / t of ferrosilicon powder is added to LF furnace refining to reduce vanadium in slag, and the vanadium content in steel increases by 0.004%, using carbon powder and ferrosilicon and low-carbon ferromanganese to fine-tune other components. After meeting the requirements of the finished product, soft blow for 12 minutes, hang and cast to protect the casting, and the properties of the billet after rolling meet the requirements of the national standard. The compos...

Embodiment 3

[0020] The molten iron after vanadium extraction, C: 3.74, V: 0.040%, S: 0.033%, Cr+Ni+Cu: 0.041%, is blended into the steelmaking converter, and the end point of blowing is C: 0.06%, P: 0.011%, S : 0.025%, which meets the requirements of tapping. During the tapping process, 0.2kg / ton of silicon-aluminum-barium deoxidizer, 378kg of lime, 167kg of refining slag, 0.3kg / ton of ferrosilicon powder, and 0.008% of vanadium content, Cr +Ni+Cu: 0.019%; adding ferrosilicon powder 0.9kg / t vanadium in reduced slag for refining in LF furnace, the vanadium content in steel is increased by 0.006%, using carbon powder, ferrosilicon and low-carbon ferromanganese to fine-tune other components to meet the requirements of finished products After soft blowing for 12 minutes, then hanging and continuous casting for protection casting, the properties of the slab after rolling meet the requirements of the national standard. The composition of the finished product is: C: 0.08%, Si: 0.88%, Mn: 1.46, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com