Method for preparing fluoresent carbon nanoparticles

A carbon nanoparticle and fluorescence technology, which is applied in the fields of nanocarbon, chemical instruments and methods, luminescent materials, etc., can solve the problems of components, size, and fluorescence properties parameters that are not explored, carbon particle agglomeration, etc., and achieves no dispersion. The effect of toxicity, good dispersibility and high fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

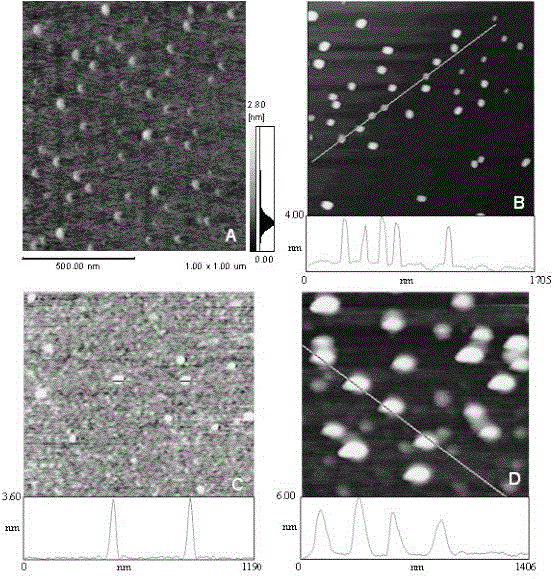

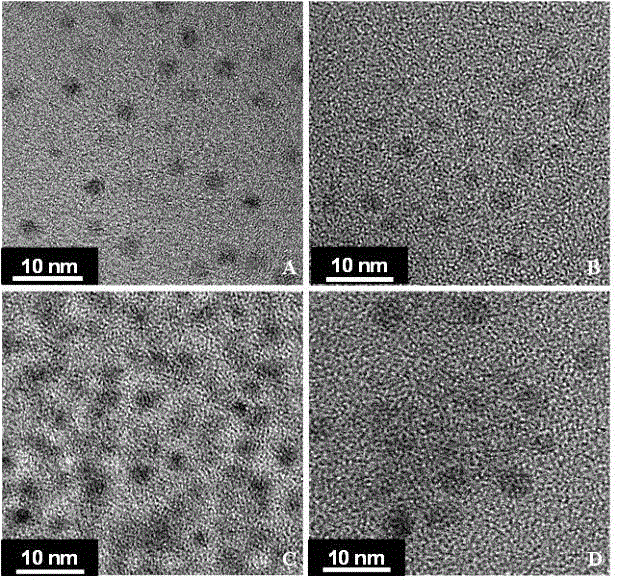

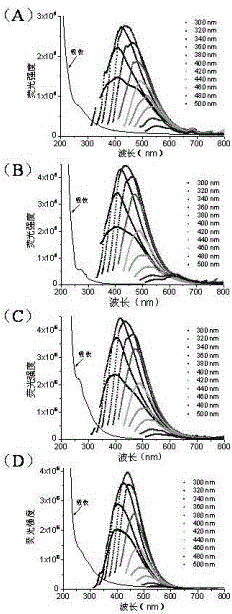

[0022] (1) Weigh 2.0 g of P123, dissolve it in 75 ml of 1.6 M hydrochloric acid solution, stir at 40°C for 2 hours until the solution is clear, then add 4.3 g of ethyl orthosilicate;

[0023] (2) After continuing to react for 65 minutes, quickly place the mixed solution in a centrifuge for centrifugation at 1000 rpm for 5 minutes to collect the precipitate;

[0024] (3) Add the precipitate to 75 ml 1.6 M hydrochloric acid solution containing 1 g P123, then add 2 g mesitylene (can be replaced by 2 g o-phenylenediamine or 2 g pyrene or 2 g phenanthroline), at 40 ° C Continue to stir for 24 hours, then transfer to 373 K for 24 hours;

[0025] (4) Suction filter the hydrothermal product through a vacuum pump, wash it with deionized water, and dry the obtained precipitate in air;

[0026] (5) Place the dried product in a quartz boat, put it in a tube furnace under the protection of nitrogen, heat up to 900°C within 10 hours, keep at the highest temperature for 2 hours, then cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com