Preparation method of carbon nano tube reinforcement asphalt based composite water-proof material

A technology of carbon nanotubes and waterproof materials, applied in building insulation materials, building components, buildings, etc., can solve the problems of carbon nanotubes being difficult to disperse uniformly, achieve the effects of improving mechanical properties, increasing antistatic, and solving winding and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

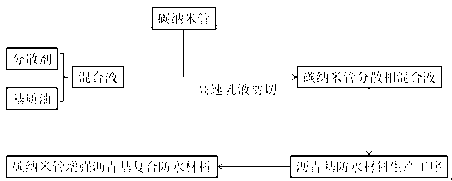

Method used

Image

Examples

Embodiment 1

[0016] (1) The raw material is composed of dispersant, carbon nanotubes, asphalt, modified rubber powder and filler, and the mass percentage of each component is: dispersant 0.2%, carbon nanotubes 4.8%, asphalt 50%, modified rubber powder 15%, filler 30%;

[0017] (2) Dissolve the pure alkylphenol polyoxyethylene ether for dispersant analysis in asphalt to prepare a mixed solution with a mass concentration of 1.5%, add carbon nanotubes to the mixed solution, and stir until uniform with a high-speed emulsion shearer to form carbon nanotubes dispersed phase mixture;

[0018] (3) Pour asphalt into the reaction kettle, heat it to 170-190°C, put in modified rubber powder to maintain the temperature of the reaction solution at 175°C, modify at a constant temperature for 3 hours, add fillers to maintain the mixing temperature at 160°C for 40 minutes, and inject step (2 ) obtained carbon nanotube dispersed phase mixed liquid, kept at a constant temperature of 150° C., and stirred for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com