Method for growing bismuth nanoparticles on oxide substrate in situ

An in-situ growth and oxide technology, applied in solid-state chemical plating, metal material coating process, coating, etc., can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

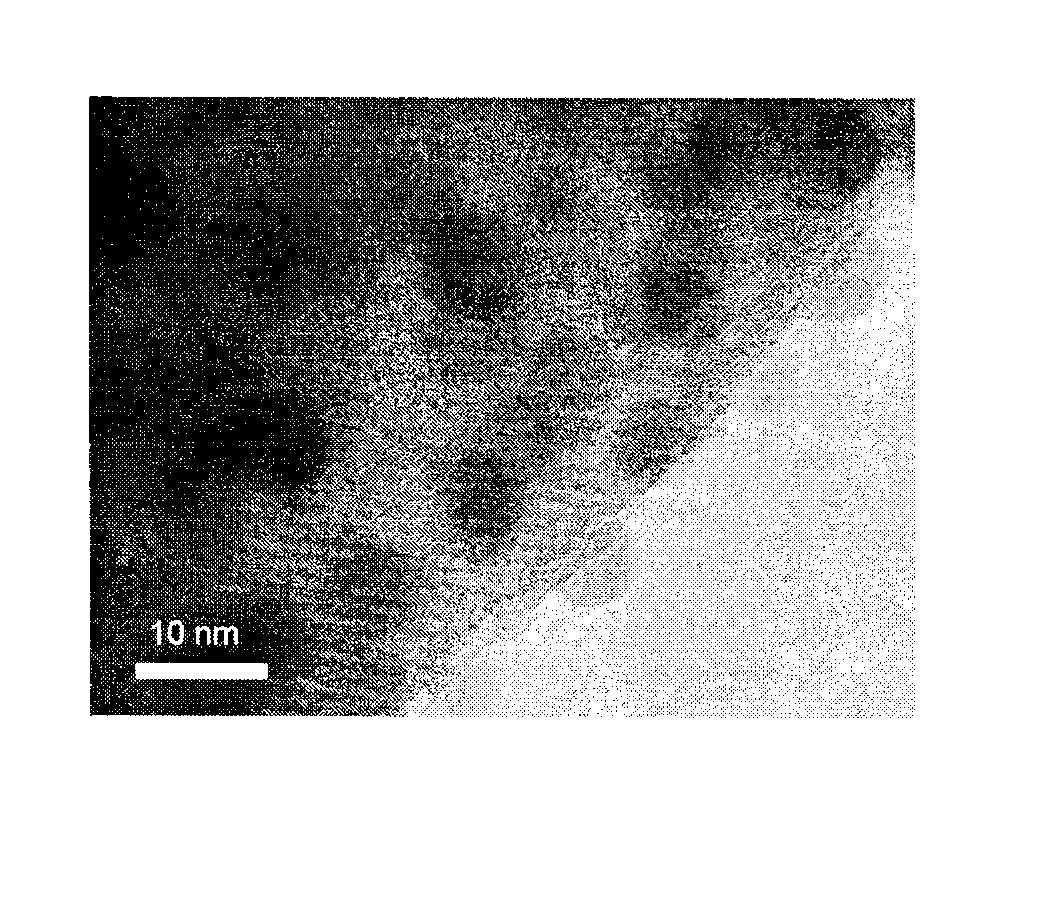

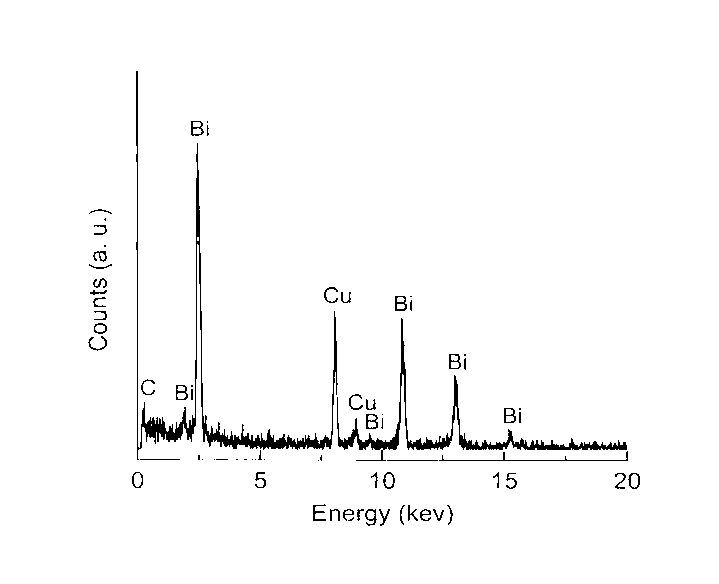

[0014] This example provides a SrBi prepared in the molten salt method 2 Ta 2 O 9 The method of in-situ growth of bismuth metal nanoparticles is to use photochemical methods to achieve SrBi 2 Ta 2 O 9 The method for preparing bismuth metal nanoparticles by in-situ reduction of trivalent bismuth in, the specific steps are as follows:

[0015] SrBi prepared by molten salt method 2 Ta 2 O 9 :

[0016] Weigh Sr(NO 3 ) 2 ?4H 2 O0.6277g, Bi 2 O 3 1.3820g, Ta 2 O 5 1.3105g, NaCl1.3744g and KCl 1.6133g, grind them in an agate mortar for 2h to make them evenly mixed, then put the ground powder into a porcelain boat, use a tube furnace to burn in the air at a temperature of 850℃ for 3h Cool to room temperature with the furnace, add deionized water to wash, filter, remove NaCl and KCl, and then use AgNO 3 Check the washed solution until there is no precipitation, and finally dry it in an oven at 100℃ for 0.5 hours to obtain SrBi 2 Ta 2 O 9 powder;

[0017] Photochemical reduction of SrBi 2 Ta 2...

Embodiment 2

[0023] This example provides a CaBi prepared by solid phase method 2 Nb 2 O 9 The method of in-situ growth of bismuth metal nanoparticles is to use photochemical methods to achieve CaBi 2 Nb 2 O 9 The method for preparing bismuth metal nanoparticles by in-situ reduction of trivalent bismuth in, the specific steps are as follows:

[0024] Preparation of CaBi by solid phase method 2 Nb 2 O 9 :

[0025] Weigh separately, CaCO 3 0.3811g, Bi 2 O 3 1.7743g, Nb 2 O 5 1.0122g, grind it in an agate mortar for 2h to make it evenly mixed, and then press the ground powder under a pressure of 8 MPa into a disk with a diameter of 10mm and a thickness of 1-2mm, and then put it into a porcelain boat. Use a tube furnace to pre-fire in the air at a temperature of 900°C for 15 hours. After it is naturally cooled to room temperature, take the sample out and continue to grind for 0.5 hours, and then press it into a disc with a diameter of 10mm and a thickness of 1-2mm under a pressure of 8MPa After sin...

Embodiment 3

[0032] This example provides a BaBi prepared in a solid phase method 2 Ta 2 O 9 The method of in-situ growth of bismuth metal nanoparticles is to use photochemical methods to achieve BaBi 2 Ta 2 O 9 The method for preparing bismuth metal nanoparticles by in-situ reduction of trivalent bismuth in, the specific steps are as follows:

[0033] Preparation of BaBi by solid phase method 2 Ta 2 O 9 :

[0034] Weigh BaCO separately 3 0.5579g, Bi 2 O 3 1.3173g and Ta 2 O 5 1.2493g, grind in an agate mortar for 2h to make it evenly mixed, and then press the ground powder into a disc with a diameter of 10mm and a thickness of 1-2mm under a pressure of 8MPa, and then put it in a porcelain boat. The furnace is pre-fired in the air at a temperature of 900℃ for 15h. After it is naturally cooled to room temperature, the sample is taken out and continues to be ground for 0.5h, and then pressed into a disc with a diameter of 10mm and a thickness of 1-2mm under a pressure of 8MPa. After sintering in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com