Method for producing metal plug for metal gate

A metal gate and metal plug technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

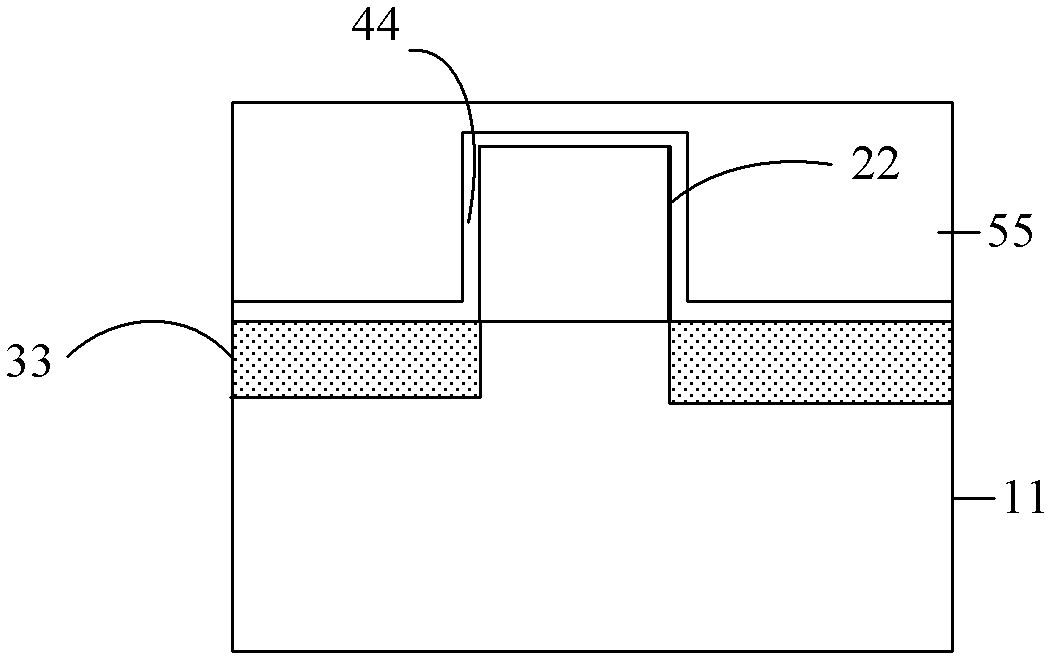

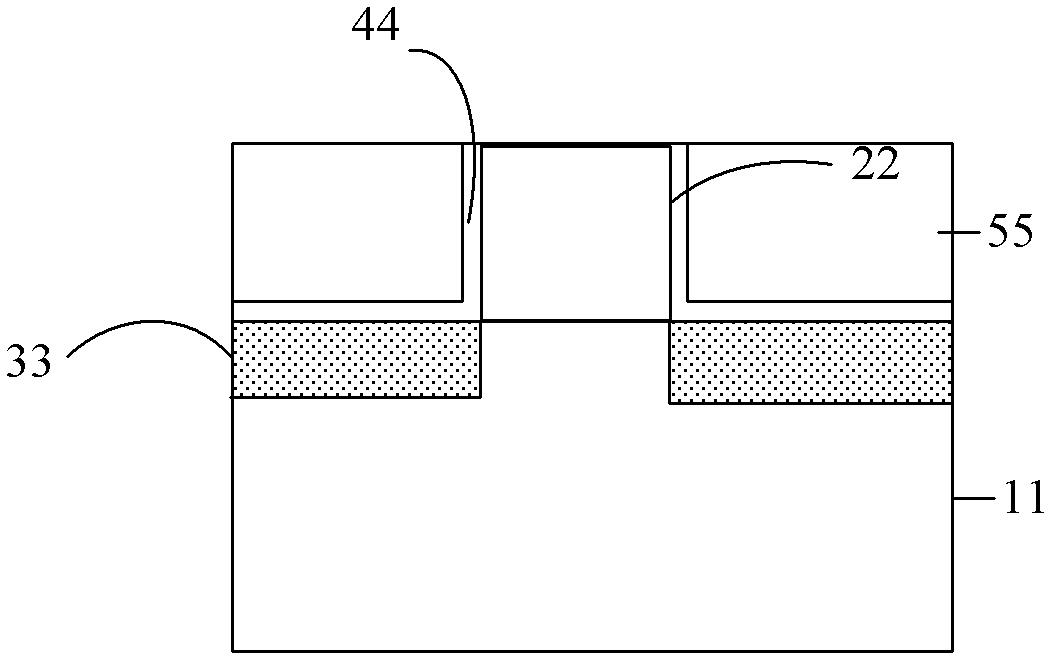

[0038] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

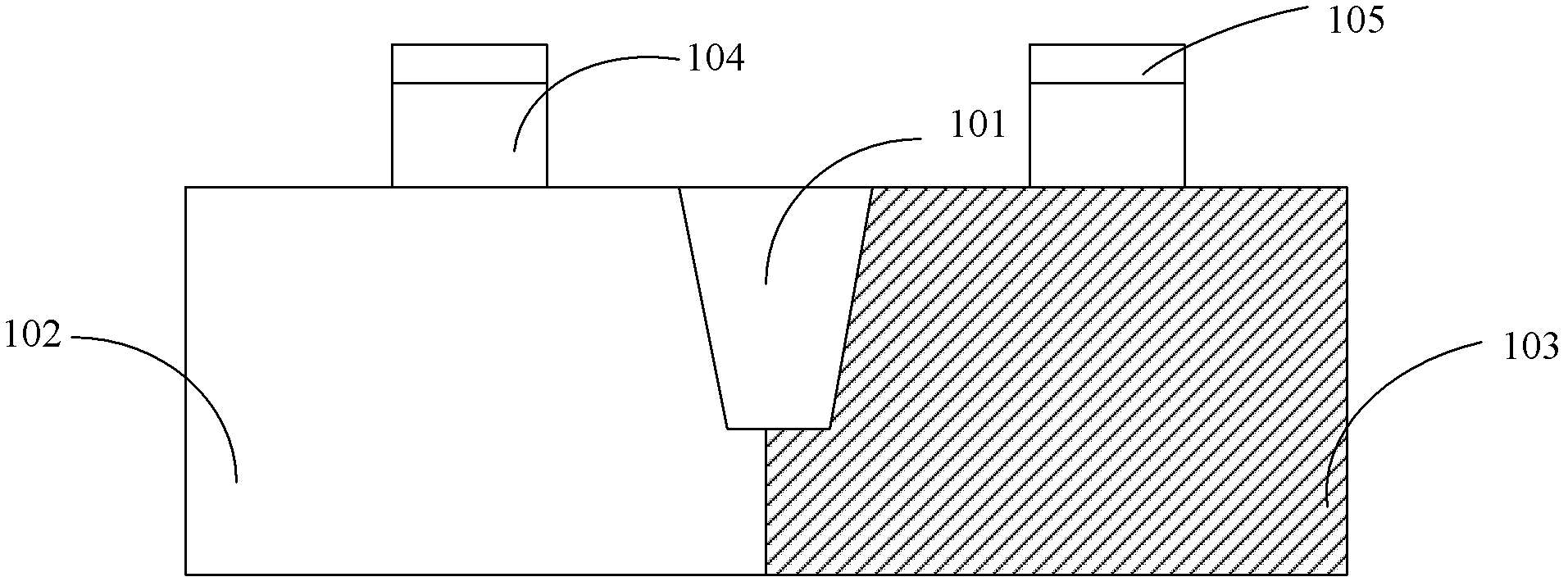

[0039] It can be seen from the background technology that in order to make the metal plug of the metal gate in the back-end process connect to the metal gate, it is necessary to oxidize the metal gate during the process of making the metal plug of the metal gate. Layer removal is carried out by dry etching, and the material used is argon molecules, that is, argon molecules are used to sputter on the surface of the semiconductor CMOS device in the reaction chamber. In order to remove completely, the dose of argon molecules used should not be too small. However, while removing the oxide layer on the metal gate, the relatively large dose of argon molecules will also sputter the barrier layer above the active region, penetrating Through the barrier layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com