Method for preparing monotectic alloy through casting by combining laser with high-intensity magnetic field

The technology of monotectic alloy and strong magnetic field is applied in the field of laser-strong magnetic field composite casting to prepare monotectic alloy, which can solve the problems of macrosegregation, low production efficiency and uneven structure of monotectic alloy, so as to reduce the movement speed and suppress convection. , the effect of reducing tissue segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

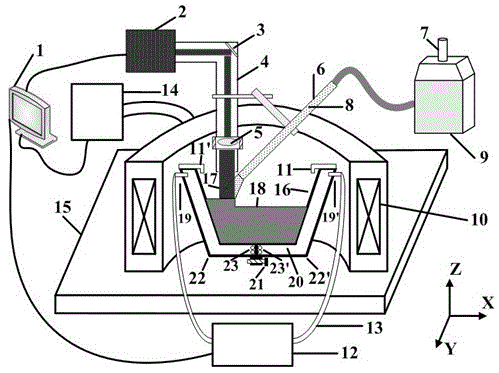

[0022] The Al-Pb binary monotectic alloy is prepared by laser-strong magnetic field composite melting and casting, and its chemical composition is Al-12 wt.%Pb. The specific implementation process is as follows figure 1 and figure 2 Shown:

[0023] (1) According to the chemical composition of the monotectic alloy, the aluminum powder with a purity of 99.9% and the lead powder with a purity of 99.9% are mixed at a mass ratio of 22:3, and added to the film-forming substance ethyl cellulose and mechanically stirred to prepare slurry;

[0024] (2) After mixing the prepared slurry evenly with a planetary ball mill, place it in a drying oven and dry it at 150°C, then mechanically grind it into monotectic alloy powder 8 with uniform particle size and good fluidity, and place it in In the loading hopper 7 of the side-axis automatic powder feeder 9;

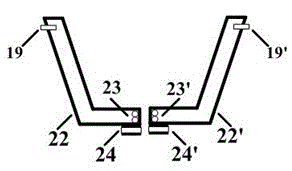

[0025] (3) Insert the fastening bolt 21 into the bolt holes 24 and 24' of the left half-copper mold 22 and the right half-copper mol...

Embodiment 2

[0032] The Ni-Pb-Cu ternary monotectic alloy was prepared by laser-strong magnetic field composite melting and casting, and its chemical composition was 60 wt.% Ni-30 wt.% Pb-10 wt.% Cu. The specific implementation process was as follows figure 1 and figure 2 Shown:

[0033] (1) According to the chemical composition of the monotectic alloy, mix nickel powder with a purity of 99.9%, lead powder with a purity of 99.9% and copper powder with a purity of 99.9% in a mass ratio of 6:3:1, and add it to the film-forming substance Prepare slurry for mechanical stirring in acrylic resin;

[0034] (2) Mix the prepared slurry evenly with a planetary ball mill, place it in a drying oven and dry it at 200°C, and mechanically grind it into monotectic alloy powder 8 with uniform particle size and good fluidity, and place it in In the loading hopper 7 of the side-axis automatic powder feeder 9;

[0035] (3) Insert the fastening bolt 21 into the bolt holes 24 and 24' of the left half-copper...

Embodiment 3

[0042] The Fe-Sn-Ge system ternary monotectic alloy was prepared by laser-strong magnetic field composite melting and casting, and its chemical composition was 50 wt.% Fe-40 wt.% Sn-10 wt.% Ge. The specific implementation process was as follows: figure 1 and figure 2 Shown:

[0043] (1) According to the chemical composition of the monotectic alloy, mix iron powder with a purity of 99.9%, tin powder with a purity of 99.9% and germanium powder with a purity of 99.9% in a mass ratio of 5:4:1, and add it to the film-forming substance Prepare slurry for mechanical stirring in polyurethane resin;

[0044] (2) After mixing the prepared slurry evenly with a planetary ball mill, place it in a drying oven and dry it at 250°C, then mechanically grind it into monotectic alloy powder 8 with uniform particle size and good fluidity, and place it in In the loading hopper 7 of the side-axis automatic powder feeder 9;

[0045] (3) Insert the fastening bolt 21 into the bolt holes 24 and 24' ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com