Microwave-assisted low-temperature acid pickling method of rare-earth ore concentrate

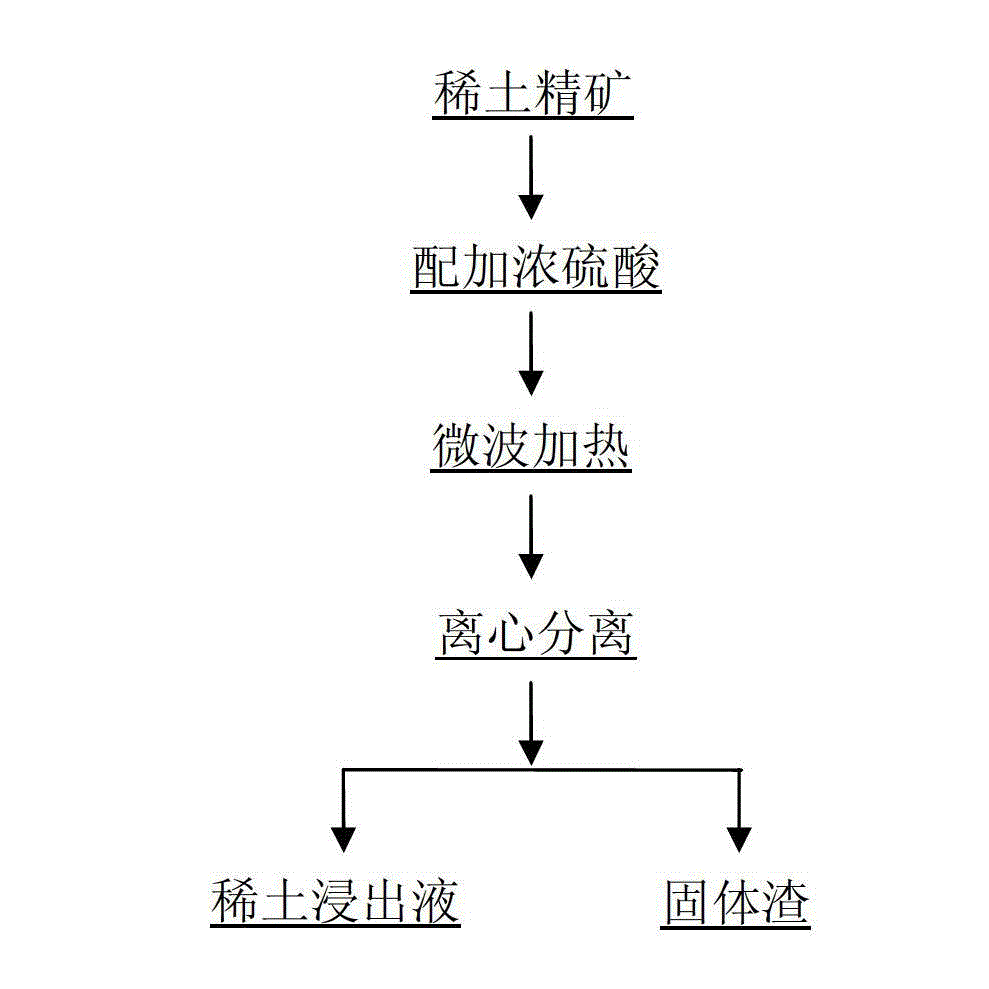

A rare earth concentrate, microwave-assisted technology, applied in the direction of process efficiency improvement, etc., can solve the problems of rare earth concentrate acid leaching decomposition rate reduction, rare earth leaching time extension, leaching rate reduction, etc., to improve the liquid-solid mass transfer rate , Shorten the production cycle and simplify the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

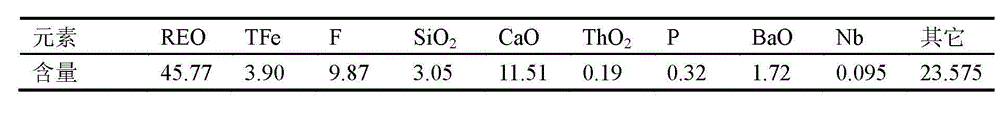

[0018] Example 1: The rare earth concentrate in this example comes from Baotou Rare Earth Hi-Tech, and its composition is shown in Table 1.

[0019] Table 1 Chemical composition of Baotou rare earth concentrate / (%, mass fraction)

[0020]

[0021] The present invention adopts the method of low-temperature acid leaching of rare earth concentrates assisted by microwaves to process rare earth concentrates. According to the mass ratio of REO content of 45.77% rare earth concentrates and sulfuric acid with a mass percentage concentration of 98%, the mass ratio is 1:1.5, and the two are mixed evenly. , heated in a chemical microwave roaster for 10 minutes at a roasting temperature of 200°C; then add deionized water to the roasted product to dilute, stir, and separate the solid and liquid in a centrifuge, so that the acid leached ore is washed three times to separate the slag from the liquid , to complete the leaching of rare earths. The final rare earth leaching rate was 96.21...

Embodiment 2

[0023] The rare earth concentrate in Example 1 is processed by microwave-assisted low-temperature acid leaching of rare earth concentrate. According to the ratio of REO content of 45.77% rare earth concentrate to sulfuric acid with a mass percentage concentration of 98%, the mass ratio is 1:2, and the two Mix well, roast in chemical microwave roasting furnace for 5 minutes, roasting temperature is 200 ℃; then roast in muffle furnace for 10 minutes, add deionized water to the roasted product and stir for 30 minutes, and carry out solid-liquid separation in centrifuge, so Wash the acid leaching ore three times, separate the slag liquid, and complete the leaching of rare earth. The final rare earth leaching rate was 99.08%, and the content of thorium in the slag was 0.034%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com