Method for improving interfacial bond strength of copper/aluminum cold rolling composite ultrathin strip

An interface bonding strength, ultra-thin technology, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of low plasticity and broken strips of composite thin strips, and achieve the effects of improving plasticity reserve, accelerating diffusion speed and reducing average size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Magnetic field heat treatment process of 0.12mm ultra-thin copper / aluminum cold-rolled composite strip

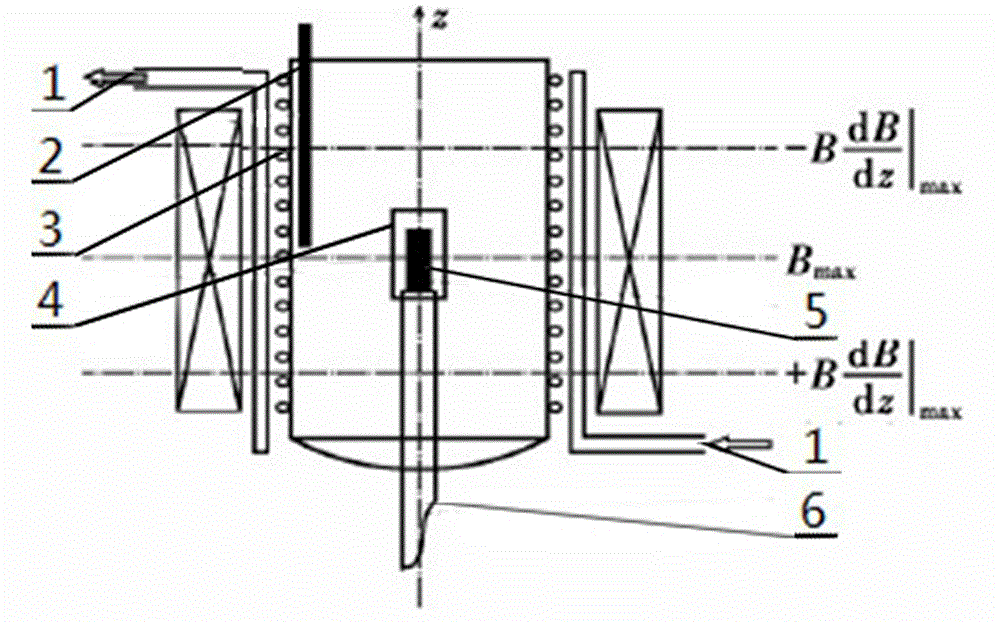

[0028] Use MVH-30 strong magnetic field heating furnace for annealing treatment. During heat treatment, cut the compounded composite tape into small pieces of 3.4cm×1cm, put the sample into a graphite crucible, and apply a positive magnetic field from 0T to 0.5 T, and then start to heat the sample. After rising to 380°C at a heating rate of 5°C / s, keep it at 380±3°C for 5 minutes, then start to cool down, and cool to room temperature at an average cooling rate of 15°C / min. When the temperature drops to room temperature, reduce the magnetic field strength to 0T, and take out the sample.

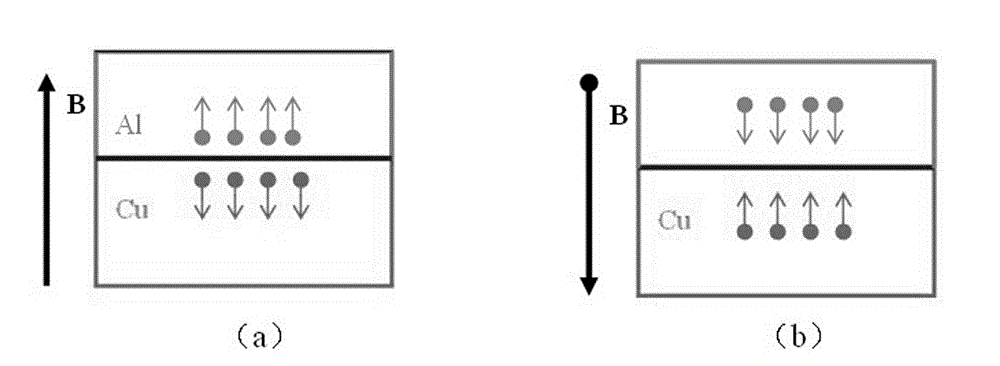

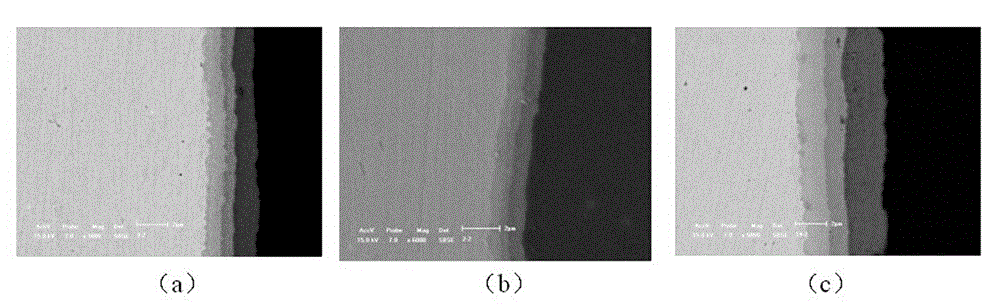

[0029] image 3 The surface electron micrographs of the 0.12mm ultra-thin composite tape interface without applying a magnetic field (a), applying a positive magnetic field (b) and applying a negative magnetic field (c). Although metal copper and aluminum are non-magnetic materials...

Embodiment 2

[0035] Magnetic field heat treatment process of 0.10mm ultra-thin copper / aluminum cold-rolled composite strip

[0036] Use MVH-30 strong magnetic field heating furnace for annealing treatment. During heat treatment, cut the compounded composite tape into small pieces of 3.4cm×1cm, put the sample into a graphite crucible, and apply a positive magnetic field from 0T to 0.01 T, then start to heat the sample, after raising the temperature up to 350°C at a heating rate of 8°C / s, keep it at 350±3°C for 10 minutes, then start to cool down, and cool it to room temperature at an average cooling rate of 10°C / min. When the temperature drops to room temperature, reduce the magnetic field strength to 0T, and take out the sample. The average size of the composite interface of the obtained sample is 1.1 μm, the shear strength is 98 MPa, the copper layer and the aluminum layer are completely recrystallized, and the type of interface compound is Al 2 Cu, AlCu, Al 4 Cu 9 , The yield strength...

Embodiment 3

[0038] Magnetic field heat treatment process of 0.15mm ultra-thin copper / aluminum cold-rolled composite strip

[0039] Use MVH-30 strong magnetic field heating furnace for annealing treatment. During heat treatment, cut the compounded composite tape into small pieces of 3.4cm×1cm, put the sample into a graphite crucible, and apply a positive magnetic field from 0T to 6T , and then start to heat the sample. After rising to 450°C at a heating rate of 10°C / s, keep it at 450±3°C for 30 minutes, then start to cool down, and cool to room temperature at an average cooling rate of 20°C / min. When it is down to room temperature, reduce the magnetic field intensity to 0T, and take out the sample. The average size of the composite interface of the obtained sample is 1.3 μm, the shear strength is 102 MPa, the copper layer and the aluminum layer are completely recrystallized, and the type of interface compound is Al 2 Cu, AlCu, Al 4 Cu 9 , The yield strength of the composite tape is 79MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com