Preparation method for tussah silk glutin powder

A manufacturing method and sericin technology are applied in the manufacturing field of tussah sericin powder, and can solve the problems of restricting the development and utilization of sericin, high purity, poor water solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

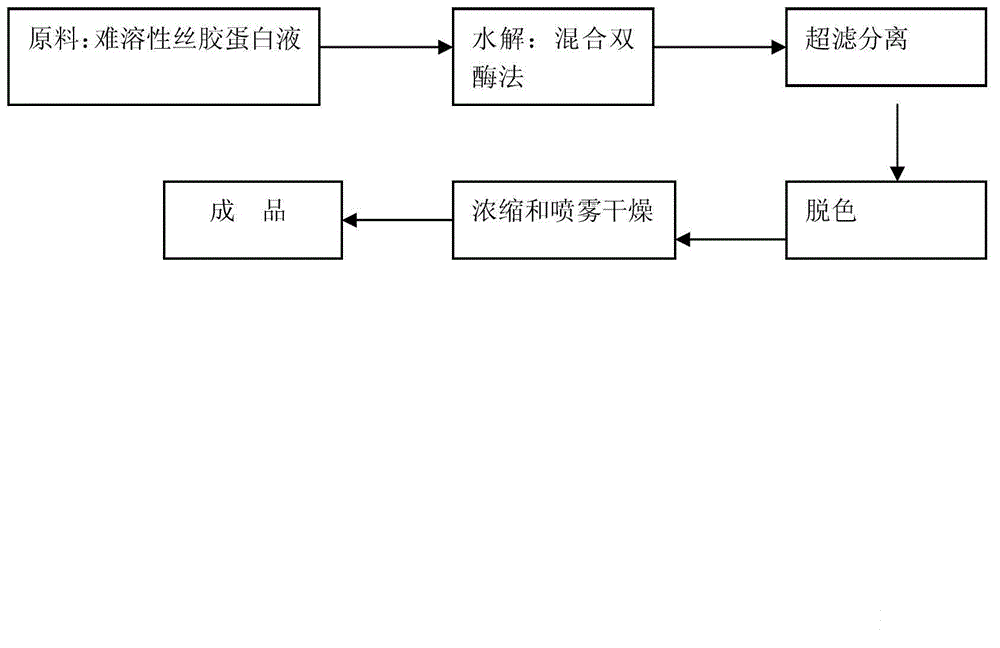

[0016] Example: Easily soluble tussah sericin powder is prepared from insoluble sericin liquid.

[0017] Its manufacturing process is as follows:

[0018] 1. Raw material preparation: insoluble sericin solution.

[0019] 2. Hydrolysis: The hydrolysis process is a mixed double-enzyme method. Select dispase and trypsin. Among them: the ratio of neutral protease: trypsin is 2:1, the hydrolysis time is 6 hours, the hydrolysis temperature is 40°C, and the hydrolysis pH value is 7.0.

[0020] 3. Ultrafiltration separation: adopt ultrafiltration membrane components and process methods. An ultrafiltration membrane with a molecular weight cut-off of 2000 was used. The concentration of sericin solution is 7.25g / L, the ambient temperature is 15-25°C, the working pressure of the membrane is 0.18Mpa, and the retention rate of sericin is 88%.

[0021] 4. Decolorization: Since sericin is recovered from degumming wastewater, its color is taupe, which affects the use effect of sericin, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com