Phosphorus-contained flame-retarding nano-class ethanediol polyterephthalate/laminated silicate composition and its preparing process and application

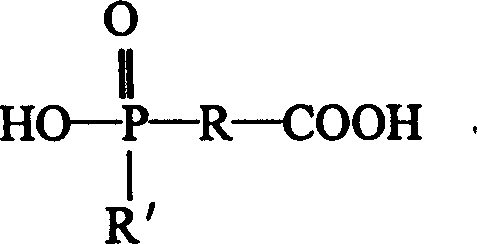

A technology of ethylene glycol phthalate and nano-composite materials, which is applied in the field of phosphorus-containing flame-retardant polymer/inorganic salt nano-composite materials and its preparation, and can solve the problems of reduced heat release rate and difficulty in flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

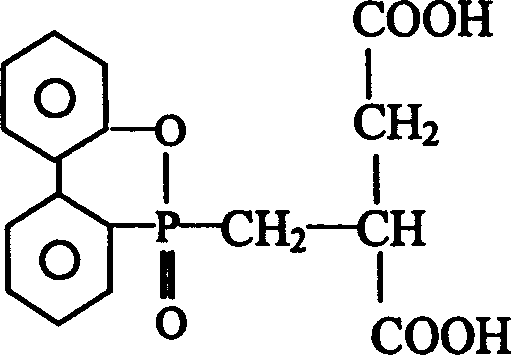

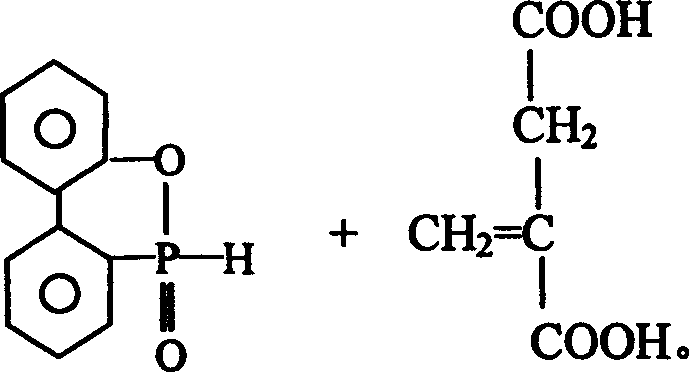

[0032] First, add 44 grams of montmorillonite with a total amount of cation exchange of 90meq / 100g into 1100 grams of dispersion medium water and stir at high speed to form a stable suspension; then add 16.16 grams of octadecyltrimethylammonium chloride Add, heat up to 70°C and stir well, then filter the sediment in the lower layer, wash it with water 2 to 3 times, fully centrifuge and dry it; then add 3032.81 grams of dimethyl terephthalate (DMT) and 1367.19 grams of ethylene glycol In the (EG) monomer, stir and mix well again, raise the temperature to 160-230°C for 2.5-4 hours of transesterification reaction; then add 183.33 grams of reactive phosphorus-containing flame retardant hydroxyphenoxyphosphine acrylic acid, catalyst antimony trioxide 1.375g, mix evenly, heat up to 245-275°C and evacuate to below 60Pa, polymerize for 2-3 hours, and the obtained phosphorus-containing flame-retardant polyethylene terephthalate / layered silicate nanocomposite material The performance is...

Embodiment 2

[0034] The preparation method of the present embodiment is the same as that of Embodiment 1, omitted. The difference is: ① the amount of layered silicate added is 110 grams; ② the layered silicate is mecca stone with a total cation exchange amount of 80meq / 100g; ③ the catalyst is antimony acetate. The properties of the composite material obtained in this embodiment are shown in the attached table.

Embodiment 3

[0036] First, add 220 grams of montmorillonite with a total amount of cation exchange of 90meq / 100g into 5500 grams of dispersion medium water and stir at high speed to form a stable suspension; then add 80.8 grams of intercalation agent octadecyltrimethylammonium chloride Add, heat up to 75°C and stir well, then filter the lower sediment, wash with water 2 to 3 times, fully centrifuge and dry; then add 2958.50 grams of terephthalic acid (PTA) and 1441.50 grams of ethylene glycol (EG) and 180.38 grams of phosphorus-containing flame retardant hydroxyphenoxyphosphine propylene, fully stirred and mixed again, and raised the temperature to 160-230 ° C for 1.5-3 hours of transesterification reaction; then added 1.3742 grams of catalyst antimony trioxide and mixed evenly, heated Heat to 245-275°C and vacuum below 60Pa, polymerize for 2-3 hours to obtain phosphorus-containing flame-retardant polyethylene terephthalate / layered silicate nanocomposite material, and its properties are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com