Iron and nitrogen doped carbon black catalyst and preparation method thereof

A catalyst and co-doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of complex preparation methods and high equipment requirements, and achieve broad application prospects and high oxygen reduction activity , The effect of promoting the commercialization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put 0.1g of Black Pearl 2000 (hereinafter referred to as BP 2000) and 0.5g of melamine into a high-speed shimmy ball mill (Nanjing Yifan, model GM-3B), and high-speed ball mill for 4 hours. After the temperature of the ball mill tank dropped to room temperature, the obtained mixed powder containing carbon, nitrogen and iron was placed in a single-temperature zone slide rail furnace, and heated at 1.01×10 5 pa, high temperature treatment at 900°C for 1 hour to obtain iron and nitrogen co-doped carbon black catalyst. After the temperature drops to room temperature, take it out and set aside. Measured by ICP: the ratio of carbon, nitrogen and iron atoms is 10:1:0.5.

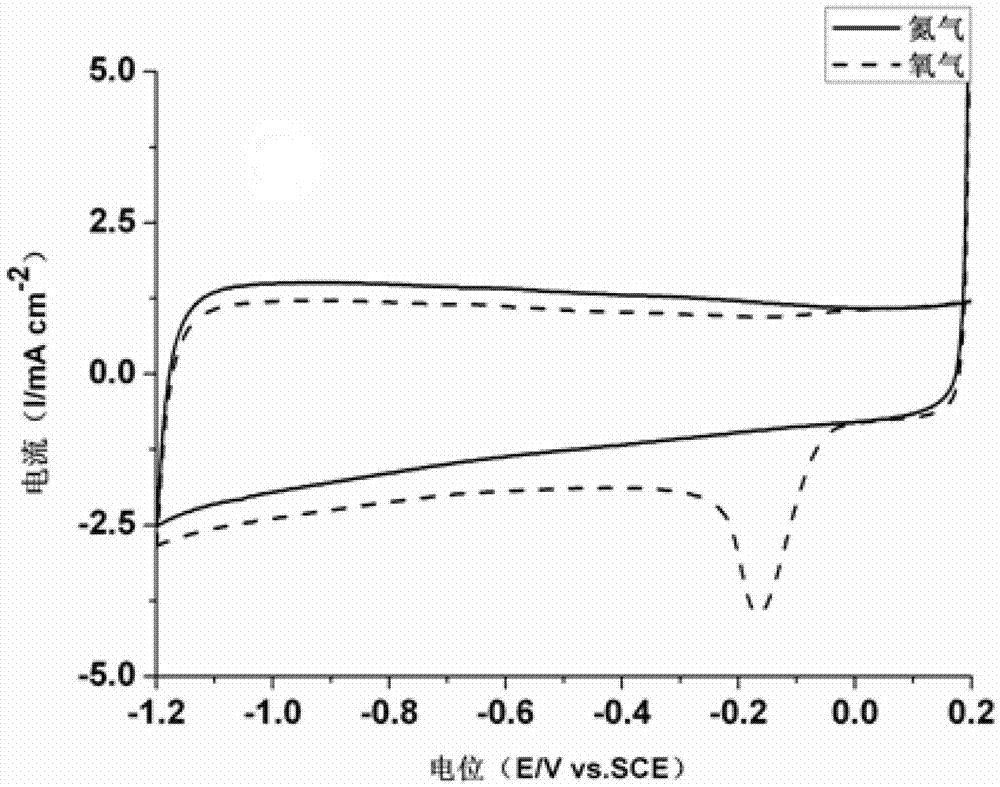

[0040]Add 5 mg of the above-prepared iron-nitrogen co-doped carbon black catalyst to 100 μL of Nafion solution with a mass concentration of 5%, and ultrasonically disperse for 30 min to obtain a solution; 10 μL of the solution is drip-coated on a rotating disk electrode, and dried at room temperature Finall...

Embodiment 2

[0044] Put 0.1g of BP 2000 and 1g of melamine into a high-speed pendulum-type ball mill (Nanjing Yifan, model GM-3B), and perform high-speed ball milling for 4 hours. After the temperature of the ball mill tank dropped to room temperature, the obtained mixed powder containing carbon, nitrogen and iron was placed in a single-temperature zone slide rail furnace, and heated at 1.01×10 5 pa, high temperature treatment at 900°C for 1 hour to obtain iron and nitrogen co-doped carbon black catalyst. After the temperature drops to room temperature, take it out and set aside. Measured by ICP: The ratio of carbon, nitrogen and iron atoms is 10:3:1.

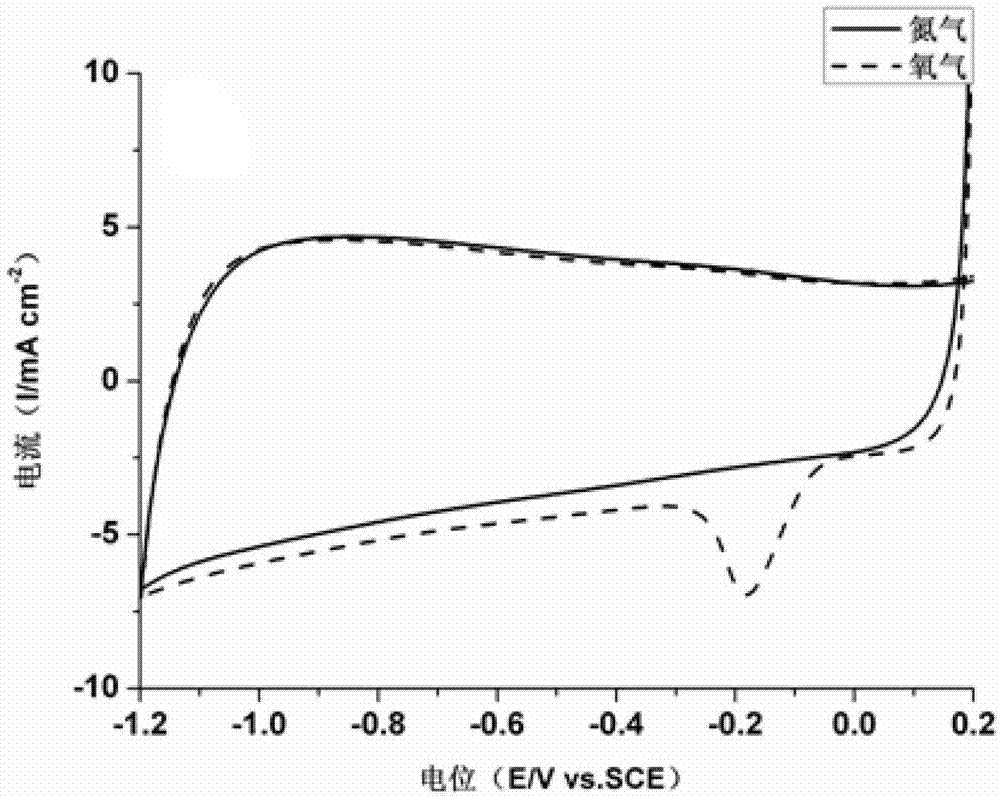

[0045] Add 5 mg of the above-prepared iron-nitrogen co-doped carbon black catalyst to 100 μL of Nafion solution with a mass concentration of 5%, and ultrasonically disperse for 30 min to obtain a solution; 10 μL of the solution is drip-coated on a rotating disk electrode, and dried at room temperature Finally, the thin film electrode is o...

Embodiment 3

[0049] Put 0.1g of BP 2000 and 2g of melamine into a high-speed pendulum-type ball mill (Nanjing Yifan, model GM-3B), and perform high-speed ball milling for 7 hours. After the temperature of the ball mill tank dropped to room temperature, the obtained mixed powder containing carbon, nitrogen and iron was placed in a single-temperature zone slide rail furnace, and heated at 1.01×10 5 pa, high temperature treatment at 900°C for 5 hours to obtain iron and nitrogen co-doped carbon black catalyst. After the temperature drops to room temperature, take it out and set aside. Measured by ICP: The ratio of carbon, nitrogen and iron atoms is 10:5:1.

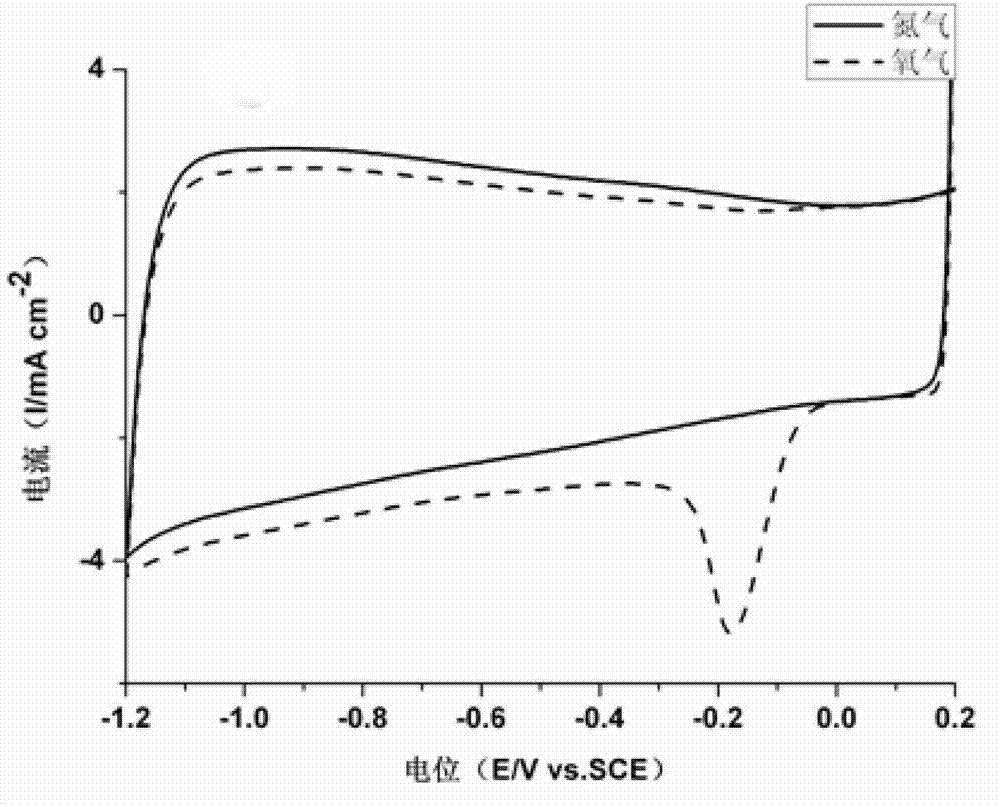

[0050] Add 5 mg of the above-prepared iron-nitrogen co-doped carbon black catalyst to 100 μL of Nafion solution with a mass concentration of 5%, and ultrasonically disperse for 30 min to obtain a solution; 10 μL of the solution is drip-coated on a glassy carbon electrode, and after drying at room temperature , to obtain a thin-film elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com