Preparation and application for non-noble metal electro-catalyst with core-shell structure

A non-precious metal, electrocatalyst technology, applied in structural parts, circuits, electrical components, etc., can solve the problems of high oxygen reduction activity of non-precious metal electrocatalysts, poor oxygen reduction activity of electrocatalysts, complicated preparation methods, etc. The effect of stable structure and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 6g commercial carbon black (Ketjen EC-600, 20-30nm, 1400m 2 / g) dispersed in 600mL3mol / LHNO 3 In the solution, reflux in a water bath at 80° C. for 1 hour, filter with suction, wash with deionized water until neutral, and dry to obtain pretreated carbon black. Add 50 mg of meso‐tetrakis (4‐methoxyphenyl) porphyrin iron and 70 mL of chloroform into a 250 mL round bottom flask, ultrasonically dissolve the porphyrin, then add 100 mg of pretreated carbon black, ultrasonic for 30 min, 65 °C, The solvent was removed by rotary evaporation under the condition of 100 rpm, and the obtained solid was heated to 800° C. under the protection of an argon atmosphere, and was stabilized for 2 hours and then naturally cooled to room temperature. After 0.5MH 2 SO 4 The solution was stirred in a water bath at 80° C. for 6 h, then suction-filtered, washed with water until neutral, and dried in vacuum at 65° C. to finally obtain a black powdery solid.

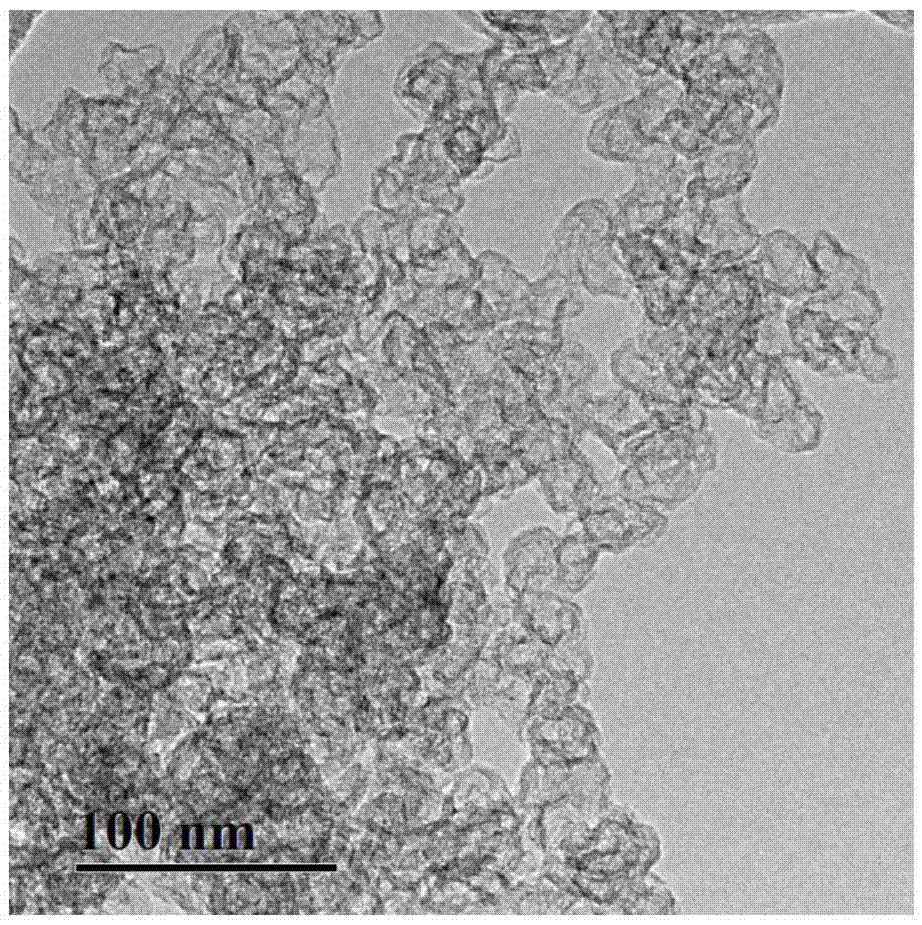

[0032] As shown in Figure 1,...

Embodiment 2

[0037] Weigh 6g commercial carbon black (Ketjen EC-600, 20-30nm, 1400m 2 / g) dispersed in 600mL3mol / LHNO 3 In the solution, reflux in a water bath at 80° C. for 1 hour, filter with suction, wash with deionized water until neutral, and dry to obtain pretreated carbon black. Add 100mg meso‐tetrakis(4‐methoxyphenyl)porphyrin iron and 70mL chloroform into a 250mL round bottom flask, ultrasonically dissolve the porphyrin, then add 100mg pretreated carbon black, ultrasonicate for 30min, 65°C, The solvent was removed by rotary evaporation under the condition of 100 rpm, and the obtained solid was heated to 800° C. under the protection of an argon atmosphere, and was stabilized for 2 hours and then naturally cooled to room temperature. After 0.5MH 2 SO 4 The solution was stirred in a water bath at 80° C. for 6 h, then suction-filtered, washed with water until neutral, and dried in vacuum at 65° C. to finally obtain a black powdery solid.

[0038] Such as Figure 5 , the obtained ...

Embodiment 3

[0043] Weigh 6g commercial carbon black (Ketjen EC-600, 20-30nm, 1400m 2 / g) dispersed in 600mL3mol / LHNO 3 In the solution, reflux in a water bath at 80° C. for 1 hour, filter with suction, wash with deionized water until neutral, and dry to obtain pretreated carbon black. Add 1000mg meso‐tetrakis(4‐methoxyphenyl)porphyrin iron and 70mL chloroform into a 250mL round bottom flask, ultrasonically dissolve the porphyrin, then add 100mg pretreated carbon black, ultrasonicate for 30min, 65°C, The solvent was removed by rotary evaporation under the condition of 100 rpm, and the obtained solid was heated to 800° C. under the protection of an argon atmosphere, and was stabilized for 2 hours and then naturally cooled to room temperature. After 0.5MH 2 SO 4 The solution was stirred in a water bath at 80° C. for 6 h, then suction-filtered, washed with water until neutral, and dried in vacuum at 65° C. to finally obtain a black powdery solid.

[0044] The morphology and performance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com