Preparation method and application of heteropolyacid/macrocyclic compound/carbon electrocatalyst

A technology of macrocyclic compounds and electrocatalysts, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of complex preparation methods of modified electrodes, difficulty in applying proton exchange membrane fuel cells, and difficult experimental scale-up of modified electrodes, achieving a huge ratio Surface area, extended service life, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Disperse 10 mg of carboxy-modified multi-walled carbon nanotubes in 25 mL of ethanol solution, add 10 mg of tetrakis (N-methylpyridyl) iron porphyrin and 20 mg of H 3 PMo 12 o 40 , sonicated at 25°C for 30min, filtered with suction, washed until the filtrate was neutral and colorless, and dried at 65°C to finally obtain a black powder solid.

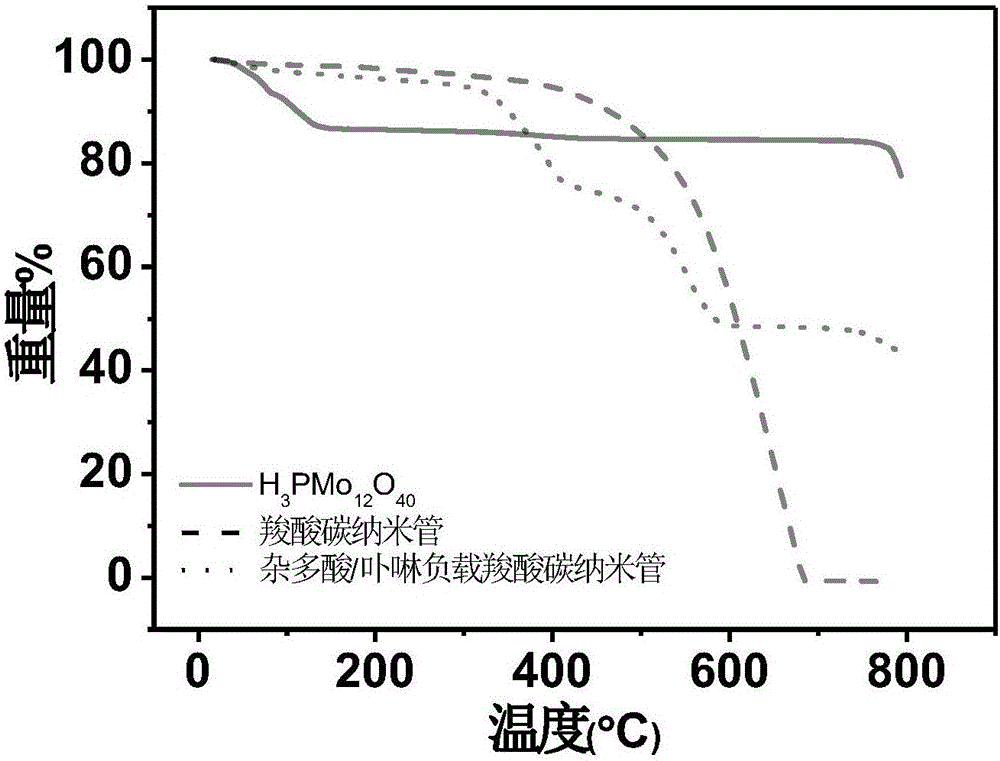

[0024] Such as figure 1 , thermogravimetric analysis showed that the heteropolyacid / porphyrin structure in the complex after washing with deionized water would not be lost, that is, the quaternary ammonium cationic macrocyclic compound and the heteropolyacid formed a water-insoluble stable structure.

[0025] Such as figure 2 , the heteropoly acid / iron porphyrin has been uniformly supported on the carbon nanotubes, and the black spots in the figure are the heteropoly acid / macrocyclic compound composite structure adsorbed.

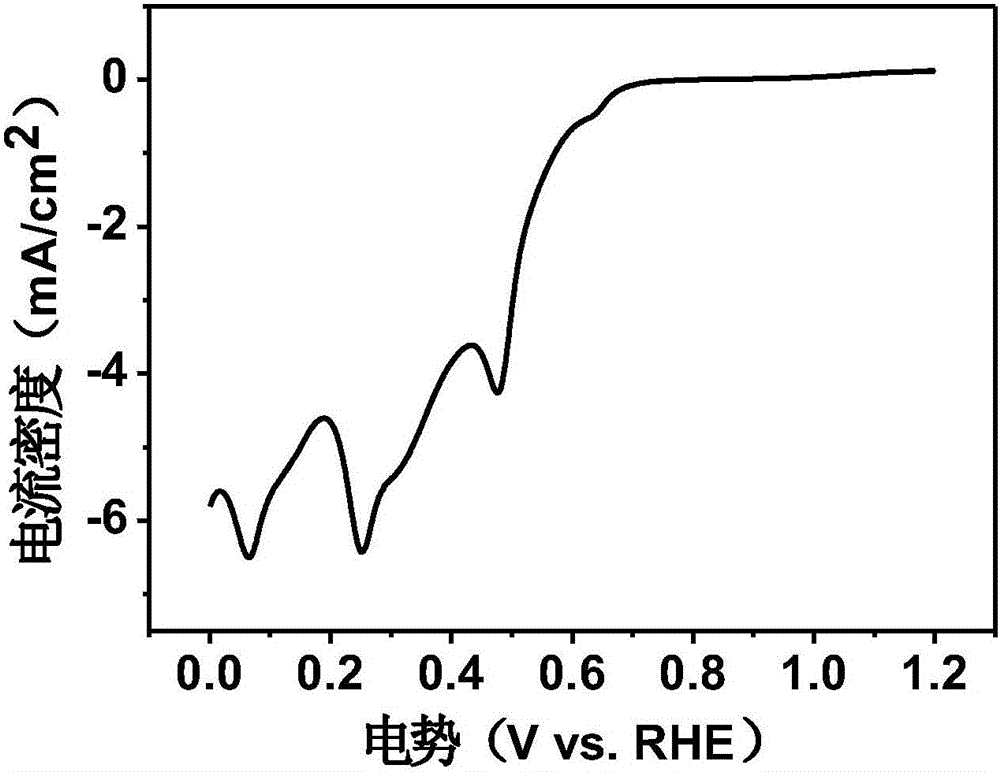

[0026] Such as image 3 , the oxygen reduction reaction test adopts the standard three-electrode metho...

Embodiment 2

[0028] With 15mg carbon black, 2mg tetrakis (N-methylpyridyl) cobalt porphyrin, 4mg H 4 SiW 12 o 40 Add it into 30mL of methanol solution, disperse it by ultrasonication at 40°C for 15min, then filter and wash with deionized water until the filtrate is colorless and neutral. Vacuum drying at 65° C. for 6 h finally obtained a black powdery solid. The morphology and performance of the catalyst obtained in Example 2 are similar to those of the sample in Example 1, and it has better overall oxygen reduction performance.

Embodiment 3

[0030] 20mg carbon nanotubes, 2mg tetrakis (N-methylpyridyl) protoporphyrin, 30mg H7 PW 8 V 4 o 40 Add it into 5mL chloroform solution, ultrasonicate at 60°C for 20min to disperse, then filter and wash with deionized water until the filtrate is colorless and neutral. After vacuum drying at 65°C for 6 h, a black powdery solid was finally obtained. The morphology and performance of the catalyst obtained in Example 3 are similar to those of the sample in Example 1, and it has better overall oxygen reduction performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com