Wireless charger with low cost

A wireless charger and wireless transmission technology, applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems that the connection length and angle cannot be changed, the product cost cannot be effectively reduced, and the marketing effect is not obvious, and the shape is easy to achieve Effects of change, product cost reduction, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In the actual product, the copper clad laminate can use PCB rigid circuit board or FPC flexible circuit board.

[0017] Embodiment two:

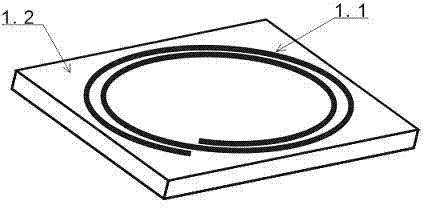

[0018] First, design the mechanical specifications of the film coil according to the technical requirements, including appearance, size, coil line width, coil line pitch, coil number, coil layer number, coil welding points, and then on the metal foil, use etching, wire cutting, The method of stamping forming forms a layered planar coil (as shown in Figure 2).

Embodiment 2

[0020] Embodiment three:

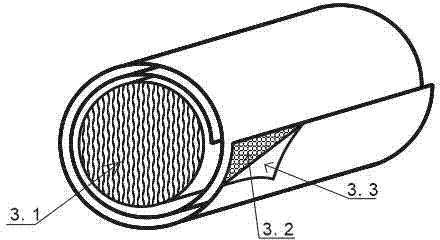

[0021] First, design the mechanical specifications of the thin film coil according to the technical requirements, including shape, size, coil line width, coil line distance, insulating material, insulating material thickness, number of coil turns, number of coil layers, coil welding points, coil thickness, and then On the outside of a reel, metal foil and insulating film (as shown in Figure 3) are wound according to the design to form a multi-layer barrel structure with metal foil and insulating film spaced apart from each other. In FIG. 3 , 3.1 is the reel, 3.2 is the metal foil, and 3.3 is the insulating film.

Embodiment 3

[0023] Embodiment four:

[0024] First, according to the mechanical structure designed by the wireless charger, design the mechanical specifications of the flexible flat cable for electrical connection, including the length, the width of the connecting metal wire, whether it needs to be folded and how to fold it, and then make the flexible flat cable according to the design . Finally, the transmitting coil and the wireless charging drive control board are electrically connected with the fabricated flexible flat cable by welding and plugging (as shown in Figure 5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com