Whitening ultraviolet-proof ethylene-propylene rubber insulation control cable for ships and manufacturing method thereof

An ethylene-propylene rubber insulation and anti-ultraviolet technology, which is used in the manufacture of insulated cables, rubber insulators, and cables/conductors. It can meet the requirements of anti-ultraviolet rays and other problems of cables, and achieve the effects of excellent resistance to ultraviolet light aging, long service life, and excellent resistance to sunlight and weathering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

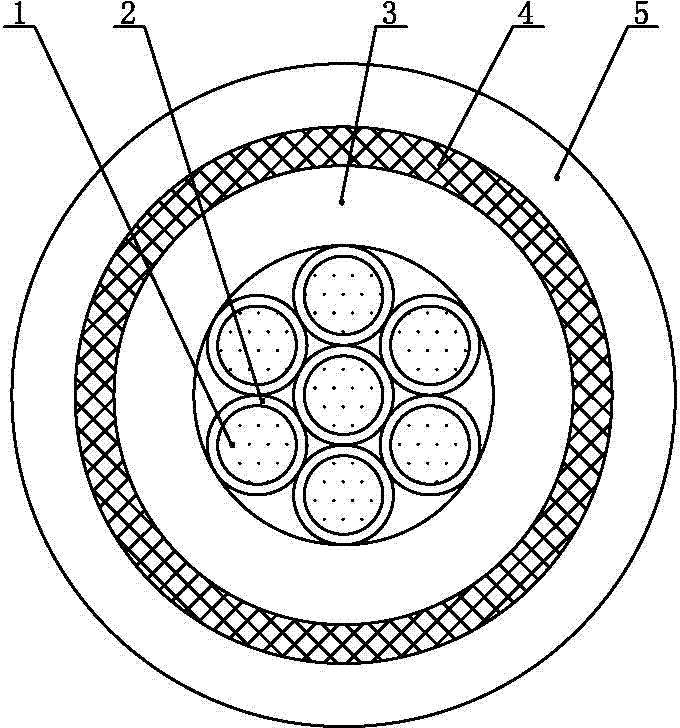

[0021] Such as figure 1 As shown, the whitening and anti-ultraviolet ethylene-propylene rubber insulated marine control cable of the present invention is manufactured according to the following steps: extruding the whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of the tinned annealed stranded copper conductor 1 of 0.35mm Insulated wire cores, a plurality of insulated wire cores are twisted to the right with a twisted pitch ratio of 20 times to form a cable core, and then an inner liner 3 is extruded on the outer periphery of the cable core, and then the inner liner 3 is wrapped around the outer periphery of the inner liner 3 Copper alloy wire braided armor layer 4 is covered, and an outer sheath 5 is extruded on the outer periphery of copper alloy wire braided armor layer 4 .

[0022] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of th...

Embodiment 2

[0026] The whitening and anti-ultraviolet ethylene-propylene rubber insulated marine control cable of the present invention is manufactured according to the following steps: extruding a whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of a 1.25mm tinned annealed stranded copper conductor 1 to form an insulated wire core , a plurality of insulated wire cores are twisted rightward with a stranded pitch ratio of 22 times to form a cable core, and then an inner liner 3 is extruded on the outer periphery of the cable core, and then the outer periphery of the inner liner 3 is coated with copper The alloy wire braided armor layer 4 is finally extruded with an outer sheath 5 around the outer periphery of the copper alloy wire braided armor layer 4 .

[0027] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of the nominal value, and the maximum thick...

Embodiment 3

[0031] The whitening and anti-ultraviolet ethylene-propylene rubber insulated marine control cable of the present invention is manufactured according to the following steps: extruding the whitening and anti-ultraviolet ethylene-propylene rubber insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 2.5mm2 to form an insulated wire core , a plurality of insulated wire cores are twisted rightward at a twisting pitch ratio of 24 times to form a cable core, and then an inner liner 3 is extruded on the outer periphery of the cable core, and then the outer periphery of the inner liner 3 is coated with copper The alloy wire braided armor layer 4 is finally extruded with an outer sheath 5 around the outer periphery of the copper alloy wire braided armor layer 4 .

[0032] Among them, the minimum thickness of the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 is not less than 90% of the nominal value, and the maximum th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com