High-temperature low-alkaline dyeing method for double-monochlorotriazine reactive dyes

A technology of reactive dyes and dyeing methods, which is applied in the field of high temperature one-bath dyeing of reactive dyes and disperse dyes, can solve the problems that reactive dyes are difficult to achieve high color yield, the difficulty of sewage treatment is increased, and fabrics are difficult to wash. The effect of hydrolysis, complete chromatography, and not easy to break bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

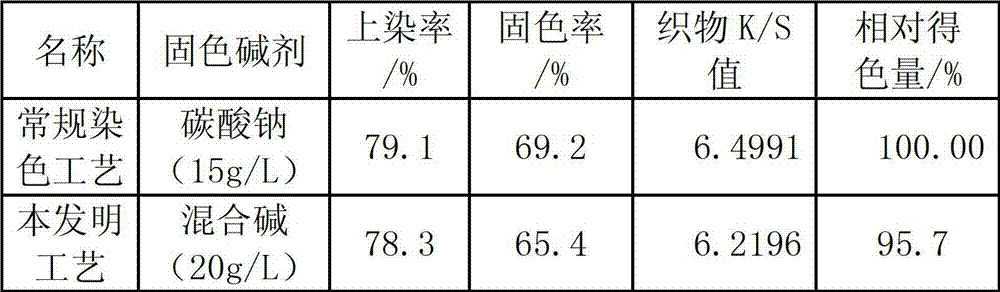

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the dyeing application of pure cotton fabric.

[0039] This embodiment takes pure cotton fabric as the application object, mainly because the dyeing application and effect detection of pure cotton fabric can be more convenient, detailed and accurate evaluation of the dyeing effect of the present invention, and this embodiment is applied to other cellulose / Polyester blended fibers and fabrics such as polyester and cotton can also achieve the same effect.

[0040] A high-temperature and low-alkali dyeing method of dichloro-s-triazine reactive dyes, which is applied to the dyeing of pure cotton fabrics, comprises the steps:

[0041] (1) Pretreatment: put the pure cotton fabric into the dyeing bath prepared according to the bath ratio of 1:8~1:30, run at room temperature for 3~5 minutes, add 0.5~1.0g / L refining agent and caustic soda 1~2g / L L (or 3g / L soda ash), finally add 3-5g / L mass fraction of 30% hydrogen peroxide, heat up to 80-95°C and run for 15-45 m...

Embodiment 2

[0078] Put 500 kg of 32S pure cotton knitted fabric into the dyeing bath prepared according to the bath ratio of 1:10, run for 3-5 minutes, add 300 kg of anhydrous sodium sulfate, run for 3-5 minutes, add liquid mixed alkali (sodium bicarbonate and tetraethylammonium hydroxide) 100KG for 3-5 minutes, finally add 4 kg of dichloro-s-triazine golden yellow, 5 kg of di-monochloro-s-triazine dark blue, 0.5 kg of di-monochloro-s-triazine red, and run for 3- After 5 minutes, heat up to 130°C at a heating rate of 1°C / min and run for 30 minutes, then cool down and drain the liquid, and the dyeing is over.

[0079] Post-treatment: First wash with warm water at 50°C, drain the liquid into the water, add 209 5 kg of detergent, heat up to 95°C at 2°C / min and run for 15 minutes, cool down and drain, then wash with cold water again, drain the liquid out of the tank, The finished product is obtained by dehydration and drying.

[0080] The standard of GB / T 3920-1997 GB / T 3921.1-1997 is used t...

Embodiment 3

[0084] Embodiment 3: The same bath dyeing application of reactive dyes and disperse dyes of polyester-cotton blended fabrics.

[0085]Put 500 kg of 35 / 65 polyester-cotton blended knitted fabric into the dyeing bath prepared according to the bath ratio of 1:10. At this time, the temperature of the dyeing bath is about 40°C, and run for 3-5 minutes; add 200 kg of anhydrous sodium sulfate, Run for 3-5 minutes; add 100 kg of liquid mixed alkali and run for 3-5 minutes, and finally add 1.25 kg of dichloro-s-triazine reactive dye yellow, 0.25 kg of di-monochloro-s-triazine reactive dye red, and di-chloro-s-triazine reactive dye red. Add 0.775 kg of reactive dye blue, add 0.6 kg of disperse yellow, 0.255 kg of disperse red, and 1.61 kg of disperse blue at the same time, run for 3-5 minutes, heat up to 130°C at a heating rate of 1°C / min and run for 30 minutes, cool down to below 70°C and discharge solution, the staining is over.

[0086] Post-treatment: First wash with warm water at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com