Size-dyeing equipment assembly with a jet cationic modification fiber system and size-dyeing method of size-dyeing equipment assembly

A modified fiber and cationic technology, applied in the field of sizing and dyeing, can solve the problems of loose yarn twist, that is, white spots, poor dyeing core penetration, poor rubbing fastness, etc., and achieve convenient color matching, complete color spectrum, and enhanced combination Effects of Strength and Bonding Depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

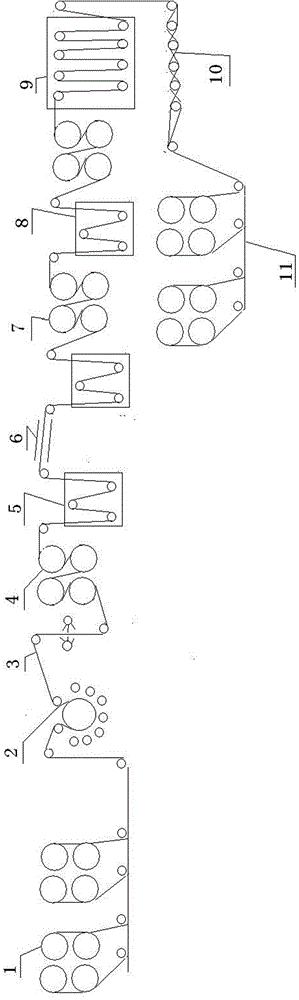

[0028] Such as figure 1 As shown, the slurry dyeing equipment assembly of the jet cation modified fiber system of this embodiment includes a constant tension multi-unit winding and unwinding system 1, a plasma processing system 2, a jet cation modification system 3, and a drying system 4 connected in sequence , Ultrasonic paint dyeing system 5, infrared constant temperature pretreatment, wet short steaming system 6, intelligent color fixing, drying system 7, sizing system 8, constant tension warp storage system 9, splitting system 10 and multi-head winding system 11.

[0029] The constant tension multi-unit winding and unwinding system of this embodiment includes an unwinding mechanism and a winding mechanism. The winding and unwinding mechanism is controlled by the following control system to control the tension change and adjustment, and operate according to the set tension range; the control system includes: programmable The controller, tension sensor, pressure sensor, cylinde...

Embodiment 2

[0033] Such as figure 1 As shown, the slurry dyeing equipment assembly of the jet cation modified fiber system in this embodiment includes a constant tension multi-unit winding and unwinding system 1, a plasma processing system 2, a jet cation modification system 3, and a drying system 4 connected in sequence , Ultrasonic paint dyeing system 5, infrared constant temperature pretreatment, wet short steaming system 6, intelligent color fixing, drying system 7, sizing system 8, constant tension warp storage system 9, splitting system 10 and multi-head winding system 11.

[0034] The constant tension multi-unit winding and unwinding system of this embodiment includes an unwinding mechanism and a winding mechanism. The winding and unwinding mechanism is controlled by the following control system to control the tension change and adjustment, and operate according to the set tension range; the control system includes: programmable The controller, tension sensor, pressure sensor, cylinde...

Embodiment 3

[0041] Such as figure 1 As shown, the slurry dyeing equipment assembly of the jet cation modified fiber system in this embodiment includes a constant tension multi-unit winding and unwinding system 1, a plasma processing system 2, a jet cation modification system 3, and a drying system 4 connected in sequence , Ultrasonic paint dyeing system 5, infrared constant temperature pretreatment, wet short steaming system 6, intelligent color fixing, drying system 7, sizing system 8, constant tension warp storage system 9, splitting system 10 and multi-head winding system 11.

[0042] The constant tension multi-unit winding and unwinding system of this embodiment includes an unwinding mechanism and a winding mechanism. The winding and unwinding mechanism is controlled by the following control system to control the tension change and adjustment, and operate according to the set tension range; the control system includes: programmable The controller, tension sensor, pressure sensor, cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com