Cleaning composition

A cleaning composition, a technology for the composition, applied in the directions of detergent compositions, non-surface-active detergent compositions, organic non-surface-active cleaning compositions, etc. Water effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

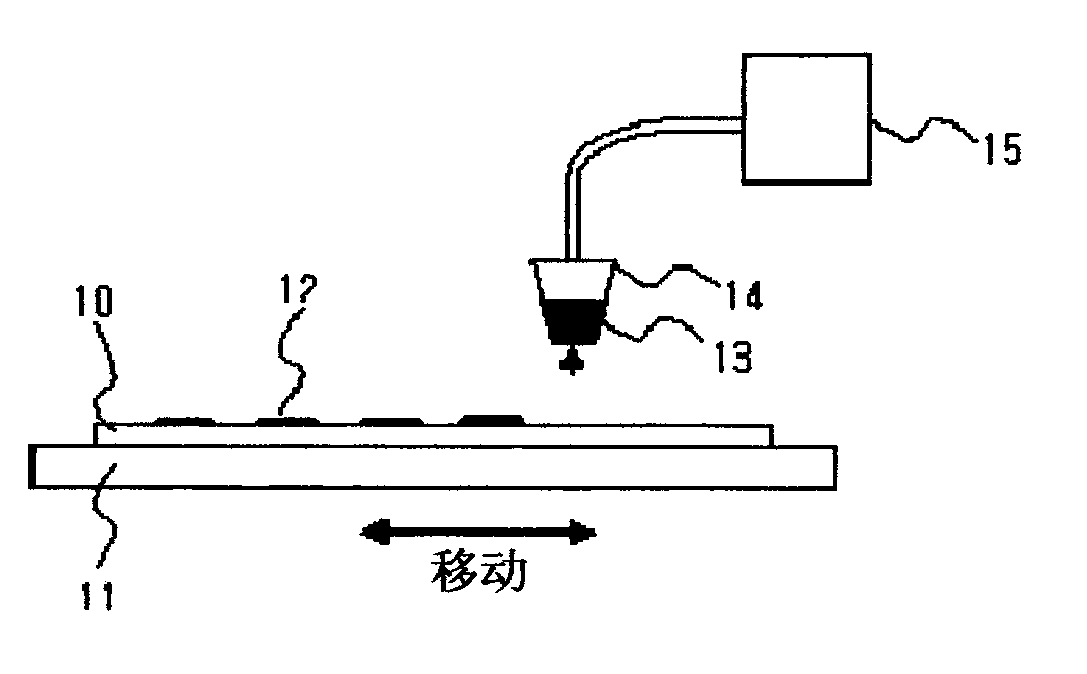

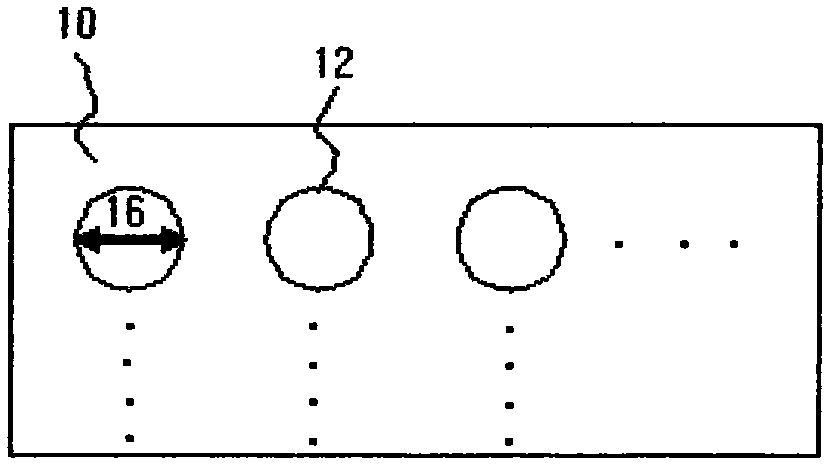

Method used

Image

Examples

example 1 to 16 and comparative example 1 to 5

[0051] Examples 1 to 16 and Comparative Examples 1 to 5: Preparation of cleaning compositions

[0052] The cleaning composition was prepared by mixing the components given in Table 1 below at the corresponding composition ratio in a mixing chamber equipped with a stirrer, and then stirring the mixture at a rotation speed of 500 rpm at room temperature for 1 hour.

[0053] Table 1

[0054]

[0055]

[0056] annotation

[0057] 1): Polyvinyl alcohol

[0058] 2): Polyvinylpyrrolidone

[0059] 3): Polyethyloxazoline

[0060] a): Ethylene glycol

[0061] b): Glycerin

[0062] c): Mannitol

[0063] TMAH: Tetramethylammonium hydroxide

[0064] TEAH: Tetraethylammonium hydroxide

[0065] EG: ethylene glycol monoethyl ether

[0066] MG: ethylene glycol monomethyl ether

[0067] EDG: Diethylene glycol monoethyl ether

[0068] MDG: Diethylene glycol monomethyl ether

[0069] MTG: Triethylene glycol monomethyl ether

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com