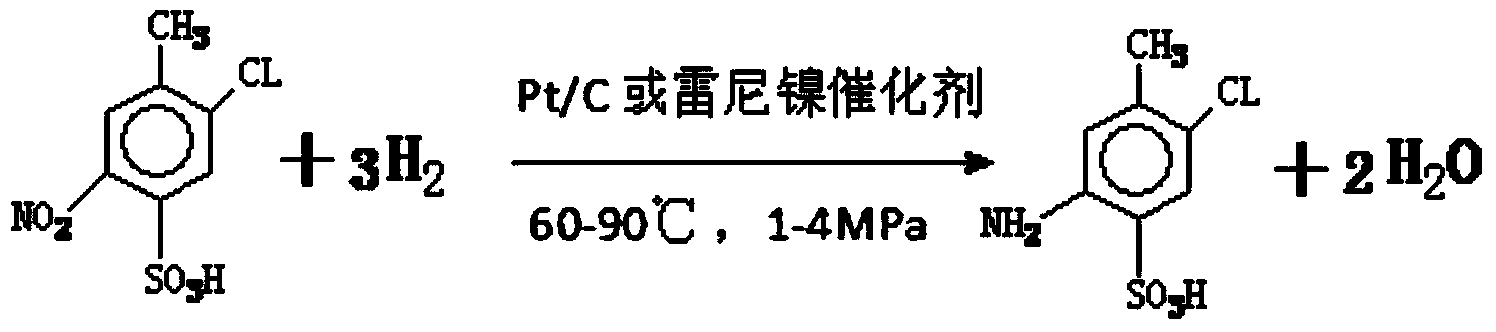

Method for preparing CLT acid (2-amino-4-methyl-5-chlorobenzene sulfonic acid) by continuous catalytic hydrogenation reduction

A catalytic hydrogenation and catalyst technology, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems of low selectivity, high equipment investment, difficult to control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

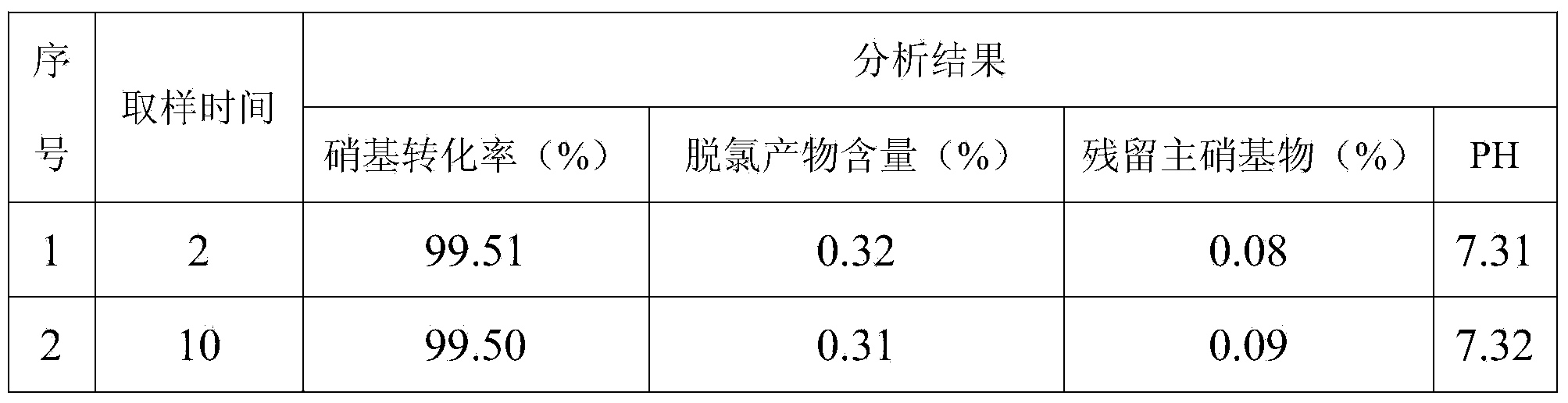

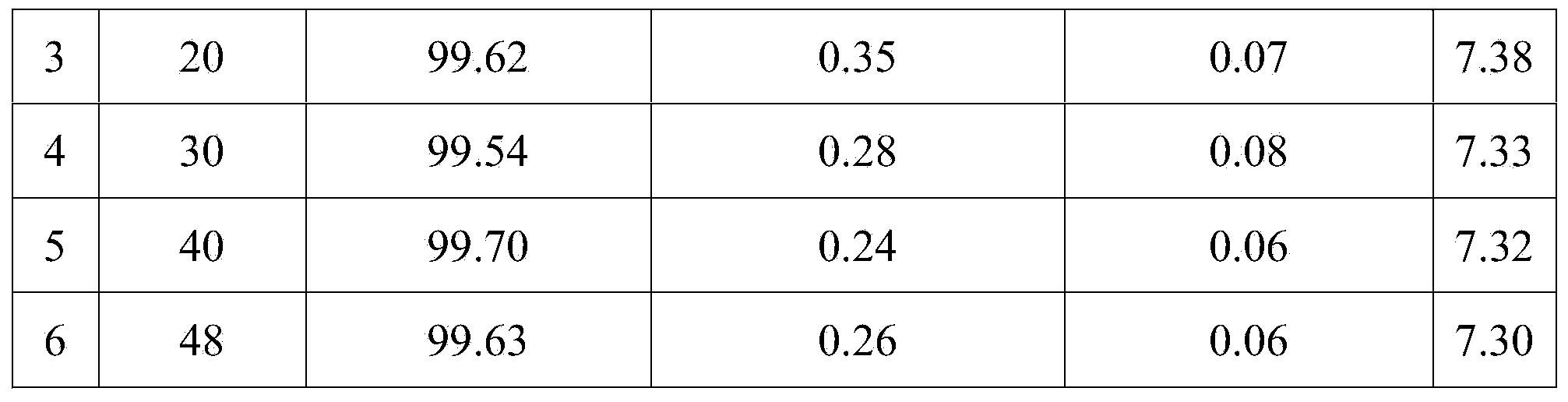

[0021] Add 300g of 10% mass percent, PH=7.2 aqueous solution of 2-amino-4-methyl-5-chlorobenzenesulfonic acid into the 2-stage series tank type continuous reactor, and add 6g into the first-stage reactor. For a Pt / C catalyst with a Pt content of 3%, add 4g of a Pt / C catalyst with a Pt content of 3% in the second-stage autoclave, replace the air with nitrogen twice, and replace the nitrogen twice with hydrogen, then start stirring , raise the temperature of the reaction material to 60°C, continuously feed hydrogen, control the hydrogen pressure at 1MPa, and then start to continuously pump 2-nitro-4 with a weight percentage of 10% and a pH of 7.5 at a feed rate of 1000ml / h -Aqueous solution of methyl-5-chlorobenzenesulfonic acid, while controlling the reaction temperature at 70°C, adopting the methods of continuous feeding of hydrogen, continuous feeding and continuous discharging, to carry out catalytic hydrogenation reduction to prepare CLT acid, and the CLT acid aqueous soluti...

Embodiment 2

[0026] Add 300g of 18% by weight of 2-amino-4-methyl-5-chlorobenzenesulfonic acid (CLT acid) aqueous solution (PH=7.5) into the 2-stage series tank type continuous reactor, in the first stage Add 10.8g3%Pt / C catalyst in the autoclave, add 3.6g3%Pt / C catalyst in the second-stage autoclave, replace the air twice with nitrogen, and replace the nitrogen twice with hydrogen, start stirring, and The temperature of the reaction material was raised to 70°C, hydrogen gas was continuously fed in, and the pressure of the hydrogen gas was controlled at 1MPa. Then, at a feed rate of 1000ML per hour, continuous pumping of 18% by weight of 2-nitro-4-methyl-5- The aqueous solution of chlorobenzenesulfonic acid (CLT acid nitro) (PH=7.5), while controlling the reaction temperature at 70°C, adopts the methods of continuous feeding of hydrogen, continuous feeding and continuous discharging, to prepare CLT acid by catalytic hydrogenation reduction, The CLT acid aqueous solution after the reaction ...

Embodiment 3

[0031]300g of 10% by weight of 2-amino-4-methyl-5-chlorobenzenesulfonic acid (CLT acid) aqueous solution (PH=7.5) was respectively added to the 3-stage series tank type continuous reactor, and in the first Add 45g90% Raney nickel catalyst to the first-stage autoclave, add 15g90% Raney nickel catalyst to the second-stage autoclave, replace the air twice with nitrogen, and replace the nitrogen twice with hydrogen, start stirring, and put the reaction Raise the temperature of the material to 65°C, continuously feed hydrogen, control the hydrogen pressure at 2MPa, and then start to continuously pump 10% by weight of 2-nitro-4-methyl-5-chloro at a feed rate of 1000ML per hour Aqueous solution of benzenesulfonic acid (CLT acid nitro) (PH=7.5), while controlling the reaction temperature at 80°C, adopting the method of continuous feeding of hydrogen, continuous feeding and continuous discharging, to prepare CLT acid by catalytic hydrogenation reduction, reaction The completed CLT acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com