Method for treating ammonia nitrogen in wastewater by using integrated process

A waste water treatment and combined process technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of unstable ammonia nitrogen in the effluent, unable to meet the discharge standards, etc., and achieve zero sewage The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

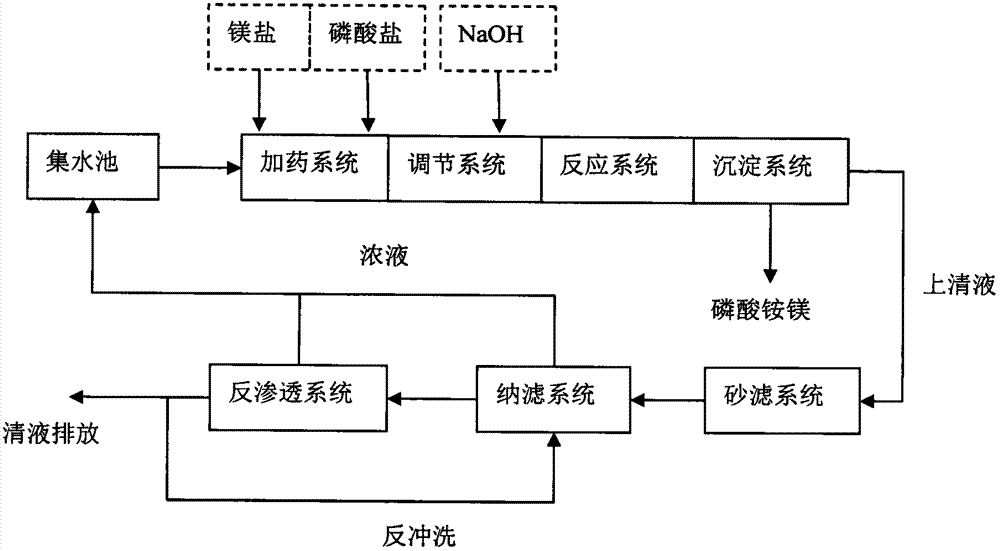

[0030] Embodiment 1: select the form of one-stage nanofiltration+one-stage reverse osmosis, reverse osmosis concentrated water is returned to sump, magnesium salt is selected magnesium sulfate for use, and phosphate is selected disodium hydrogen phosphate for use, n(N):n(P): n(Mg)=1:1.1:1.3, pH=9.5, nanofiltration clean water production rate=85%, operating pressure 1.4MPa, reverse osmosis clean water production rate=85%, operating pressure 1.6MPa;

[0031] Waste water quality: 2m 3 / h, pH=6.4, Mn 2+ Concentration 341mg / L, NH 4 + The concentration is 1080mg / L. The residence time in the stirring tank is 30min, and the residence time in the sedimentation tank is 6h. Under the above conditions, the effluent NH 4 + Concentration 9mg / L, Mn 2+ The concentration is 0.5mg / L.

Embodiment 2

[0032]Embodiment 2: select the form of one-stage nanofiltration+one-stage reverse osmosis, reverse osmosis concentrated water is returned to sump, magnesium salt selects magnesium sulfate for use, phosphate selects disodium hydrogen phosphate for use, n(N):n(P): n(Mg)=1:1.1:1.4, pH=9.5, nanofiltration clean water production rate=75%, operating pressure 1.2MPa, reverse osmosis clean water production rate=80%, operating pressure 1.4MPa;

[0033] Waste water quality: 2m 3 / h, pH=6.4, Mn 2+ Concentration 341mg / L, NH 4 + The concentration is 1080mg / L. The residence time in the stirring tank is 30min, and the residence time in the sedimentation tank is 6h. Under the above conditions, the effluent NH 4 + Concentration 6mg / L, Mn 2+ The concentration is 0.2mg / L.

Embodiment 3

[0034] Embodiment 3: Select the form of two-stage nanofiltration series connection + one-stage reverse osmosis, reverse osmosis concentrated water is returned to the sump, magnesium salt is selected magnesium chloride, and phosphate is selected disodium hydrogen phosphate, n(N):n(P): n(Mg)=1:1.1:1.3, pH=9.5, nanofiltration clean water production rate=85%, operating pressure 1.4MPa, reverse osmosis clean water production rate=90%, operating pressure 1.8MPa;

[0035] Waste water quality: 5m 3 / h, pH=6.4, Mn 2+ Concentration 341mg / L, NH 4 + The concentration is 1080mg / L. The residence time in the stirring tank is 30min, and the residence time in the sedimentation tank is 6h. Under the above conditions, the effluent NH 4 + Concentration 10mg / L, Mn 2+ The concentration is 0.3mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com