Organosilicon superhydrophobic nano-composite coating, and preparation method and use thereof

A nano-composite coating, composite coating technology, applied in coatings, chemical instruments and methods, synthetic resin layered products, etc. The performance does not meet the requirements and other problems, so as to achieve the effect of low production cost, avoiding performance degradation and simple formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

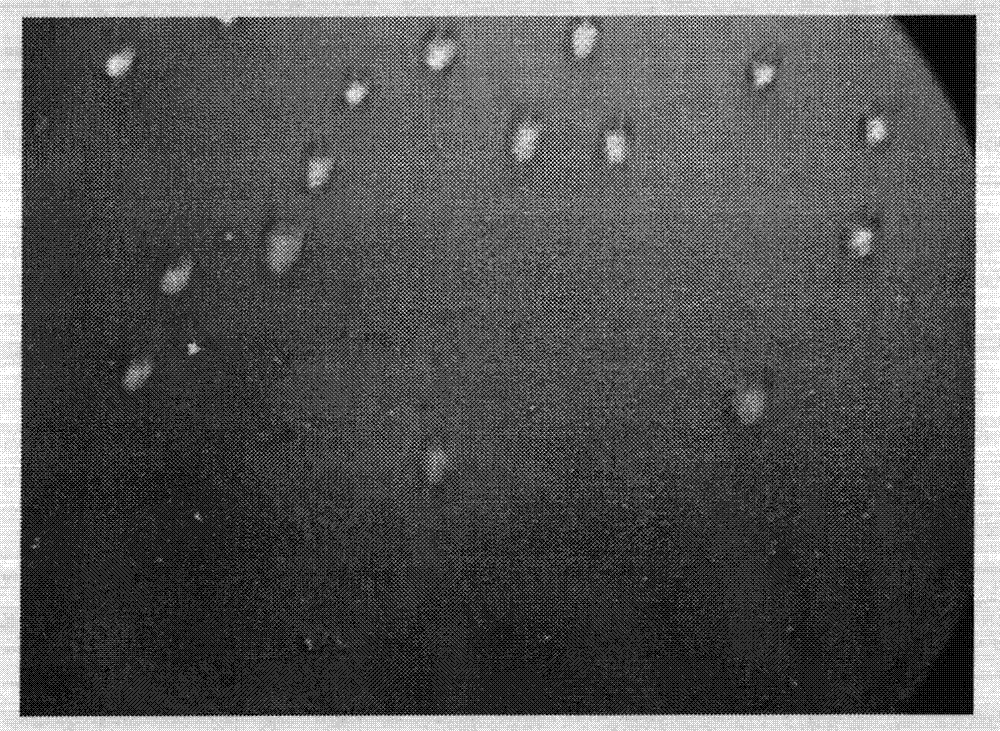

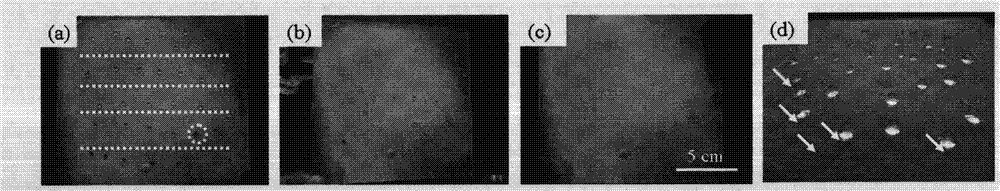

Image

Examples

Embodiment 1

[0046] First 9.6 parts by weight of silanol-terminated methyl silicone resin (sold by Chengdu Tuoli Chemical Industry Co., Ltd.) , the trade name is GC-500Z) (the weight-average molecular weight of the resin is 45,000) dissolved in 45 parts by weight of petroleum ether, after mechanically stirring for 30 minutes, spray it on the stainless steel plate base for 5s (that is, 5 seconds) under the pressure of 0.6MPa to form The inner coating (coating thickness 0.25mm) that does not contain inorganic powder, and then 0.2 parts by weight of silicon dioxide (average particle diameter 15nm, Wacker Company or Digaosha Company) modified by dimethyl dichlorosilane , trade name N20 or A200) and 0.2 parts by weight of GC-500Z dissolved in 45 parts by weight of petroleum ether and mechanically stirred for 30 minutes, then sprayed for 5 seconds under a pressure of 0.6 MPa on the silanol-terminated methyl silicone resin coating to form an outer coating layer (coating thickness 120nm), a compos...

Embodiment 2

[0049] First, 18.5 parts by weight of the silanol-terminated phenyl silicone resin (the weight average molecular weight of the resin is 60,000, produced by Chengdu Tuoli Co., Ltd.) Chemical Industry Co., Ltd.) dissolved in 40 parts by weight of tetrahydrofuran, mechanically stirred for 60 minutes, and then sprayed for 5 seconds (that is, 5 seconds) under a pressure of 0.6 MPa to form an inner coating (coating) that does not contain inorganic powder on the stainless steel plate substrate. thickness 0.4mm), and then 0.5 parts by weight of titanium dioxide modified by trichlorosilane (U.S. DuPont Company, trade name R105, average particle size 30nm) and 1 part by weight of phenyl silicone resin terminated by silanol (the weight of the resin Average molecular weight 60,000, sold by Chengdu Tuoli Chemical Industry Co., Ltd.) was dissolved in 40 parts by weight of tetrahydrofuran (THF) by mechanical stirring for 60 min, and sprayed for 5 s under a pressure of 0.6 MPa to form an outer...

Embodiment 3

[0052] First, 38.5 parts by weight of the methyl phenyl silicone resin (the weight average molecular weight of the resin is 180,000, provided by Chengdu Tuoxi) that comprises the cross-linking agent vinyl tributyl ketoxime base silane (content in the resin is 6wt%) end-capped methyl phenyl silicone resin Li Chemical Industry Co., Ltd.) was dissolved in 30 parts by weight of N,N-dimethylacetamide, and after ultrasonic dispersion for 100min, dip-coated one layer on the glass plate substrate to form an inner coating (coating) without inorganic powder layer thickness 0.8 mm). Then 1 weight part of calcium carbonate modified by KH550 (average particle diameter 100nm, product name: heavy calcium carbonate, manufacturer: Sichuan Hengtong calcium carbonate powder factory) and 0.5 weight part of the above-mentioned silanol-terminated methylphenyl silicon Resin is dissolved in 30 parts by weight of N,N-dimethylacetamide, and after ultrasonic dispersion for 100min, dip-coat one layer on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com