Special fixture for turning two end surfaces of thin-wall conical part

A special fixture and two-end technology, applied in metal processing mechanical parts, clamping, manufacturing tools, etc., can solve problems such as easy deformation, achieve the effect of short processing cycle, simple fixture structure, and overcome technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

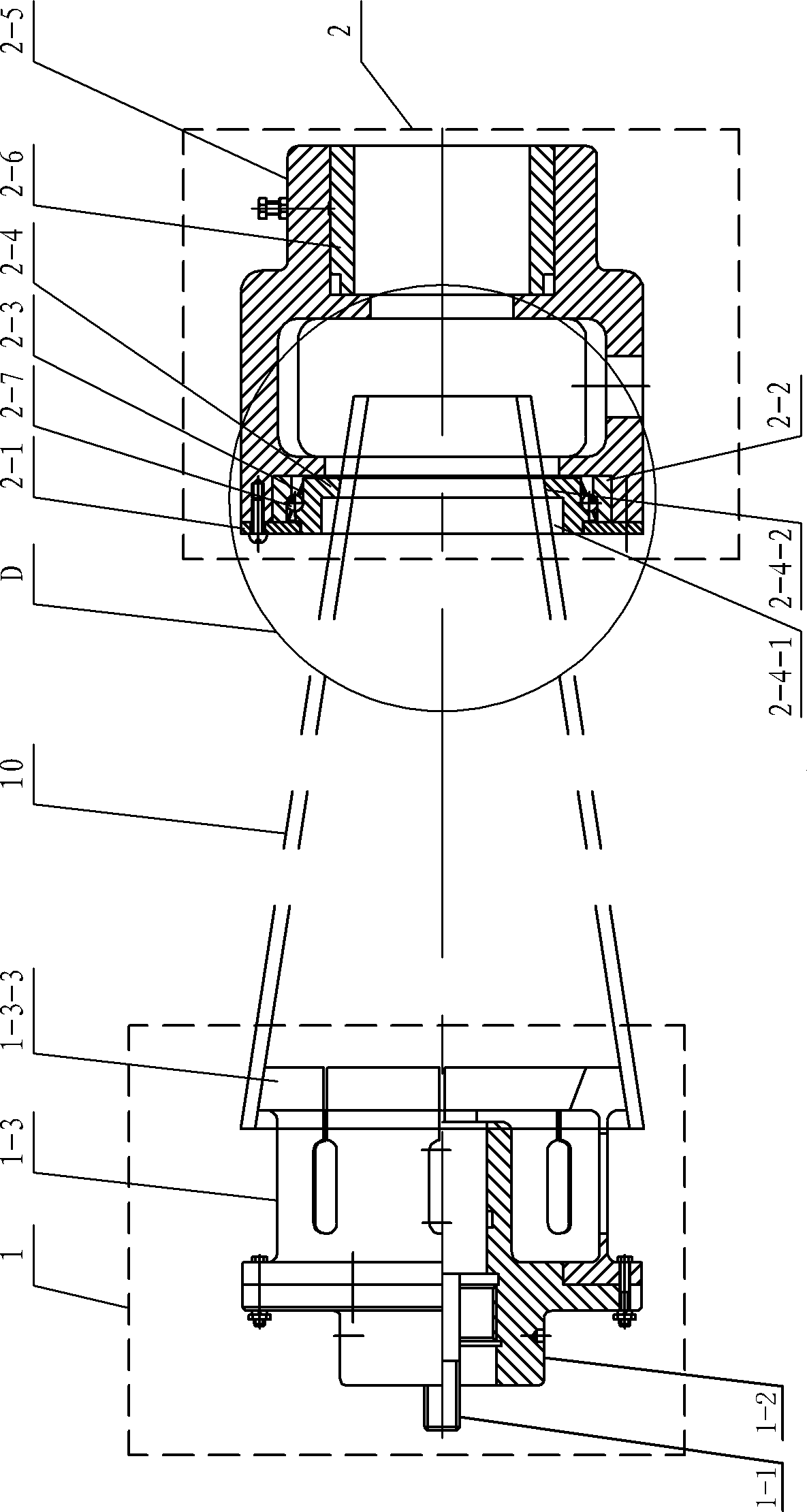

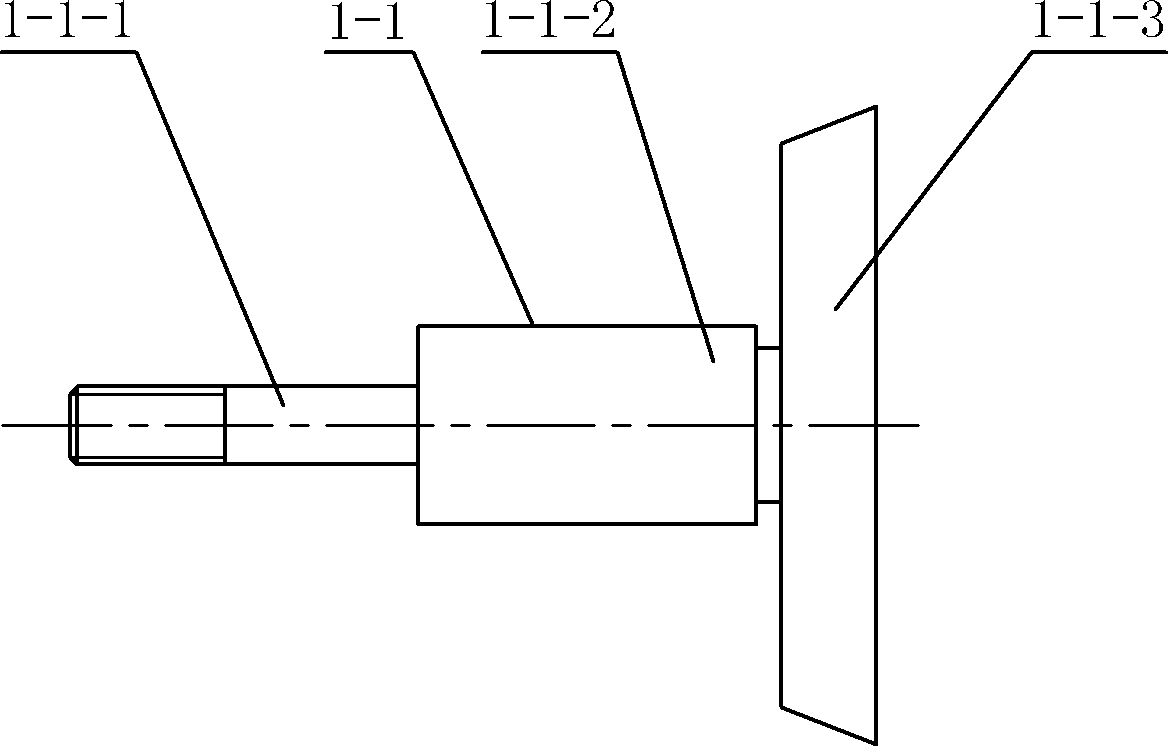

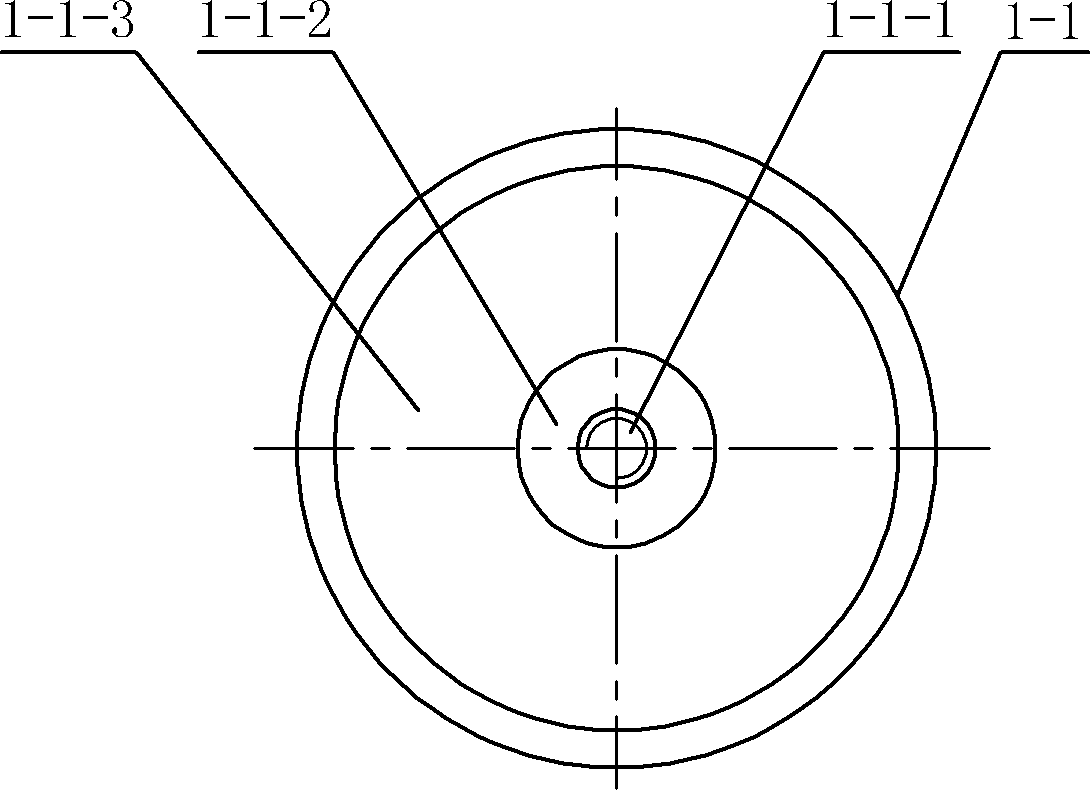

[0010] Specific implementation mode one: combine Figure 1 to Figure 13 Explain, the special fixture for the two ends of the turning thin-walled conical part of the present embodiment, the special fixture includes an elastic clamp 1 and an apical body 2, and the elastic clamp 1 and the apical body 2 are coaxially arranged; the elastic clamp 1 includes a mandrel 1 -1, the first clip body 1-2 and the elastic chuck 1-3; the tail top body 2 includes a baffle plate 2-1, an outer ring 2-2, a bead frame 2-3, an inner ring 2-4, and a second clip Concrete 2-5, bushing 2-6 and multiple balls 2-7;

[0011] The center of one side end face of the first clamping body 1-2 is provided with lathe spindle positioning hole 1-2-1 sequentially along the axial direction (to ensure that the axis of the first clamping body 1-2 is coaxial with the lathe spindle), the lathe spindle thread Connecting hole 1-2-2 (to ensure reliable connection between the special fixture and the lathe spindle, to prevent...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 7 It is explained that eight axial long holes 1-3-2-1 are evenly distributed along the circumference of the tube wall of the thin-walled circular tube 1-3-2 in this embodiment. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 6 and Figure 8 To illustrate, the slit width of the long slit 1-3-2-2 in this embodiment is 2-3mm. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com