Polyacrylonitrile carbon fiber and preparation method thereof

A polyacrylonitrile carbon fiber and polyacrylonitrile technology, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of complex process equipment, high cost, low efficiency, etc., and achieve simple production process, improve production efficiency, and control operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

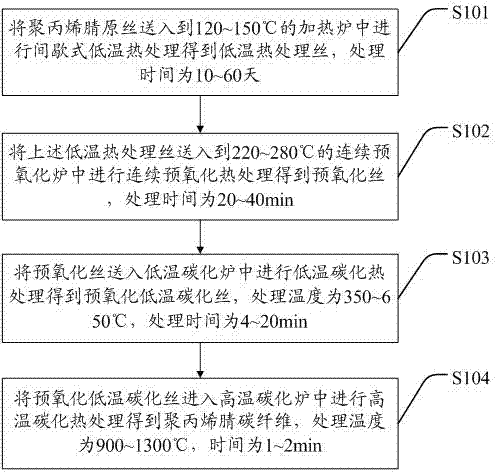

[0043] Batches of PAN precursors are first subjected to low-temperature heat treatment, and then successively undergo continuous pre-oxidation heat treatment, low-temperature carbonization heat treatment, and high-temperature carbonization heat treatment through a continuous pre-oxidation furnace, a low-temperature carbonization furnace, and a high-temperature carbonization furnace.

[0044] The temperature of the low-temperature heat treatment is 120° C., and the heat treatment time is 60 days. The color of the fiber changes from white to light yellow, and some intramolecular cyclization reactions occur in the fiber. The fibers had no stretch applied and had a shrinkage of 1%.

[0045]The continuous pre-oxidation furnace is divided into 3 temperature zones, respectively 220, 250, and 270°C, the draft ratio is 3%, the tension is 15MPa, and the total residence time is 25min. The air is passed into the furnace to promote the cyclocrosslinking and oxidation reaction of the fiber,...

Embodiment 2

[0050] Batches of PAN precursors are first subjected to low-temperature heat treatment, and then successively undergo continuous pre-oxidation heat treatment, low-temperature carbonization heat treatment, and high-temperature carbonization heat treatment through a continuous pre-oxidation furnace, a low-temperature carbonization furnace, and a high-temperature carbonization furnace.

[0051] The temperature of the low-temperature heat treatment is 120° C., and the heat treatment time is 60 days. The color of the fiber changes from white to light yellow, and some intramolecular cyclization reactions occur in the fiber. The fibers had no stretch applied and had a shrinkage of 1%.

[0052] The continuous pre-oxidation furnace is divided into 4 temperature zones, respectively 220, 240, 260, and 280°C, the draft ratio is 4.5%, the tension is 20MPa, and the total residence time is 35min. The air is passed into the furnace to promote the cyclocrosslinking and oxidation reaction of th...

Embodiment 3

[0057] Batches of PAN precursors are first subjected to low-temperature heat treatment, and then successively undergo continuous pre-oxidation heat treatment, low-temperature carbonization heat treatment, and high-temperature carbonization heat treatment through a continuous pre-oxidation furnace, a low-temperature carbonization furnace, and a high-temperature carbonization furnace.

[0058] The temperature of the low-temperature heat treatment is 130° C., and the heat treatment time is 30 days. The color of the fiber changes from white to light yellow, and some intramolecular cyclization reactions occur in the fiber. The fibers had no stretch applied and had a shrinkage of 1.5%.

[0059] The continuous pre-oxidation furnace is divided into 3 temperature zones, respectively 220, 250, and 270°C, the draft ratio is 3%, the tension is 15MPa, and the total residence time is 25min. The air is passed into the furnace to promote the cyclocrosslinking and oxidation reaction of the fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com