Manufacturing method of special welding material for electron beam welding of YGH-60 hard alloy and 45 steel

A YGH-60, electron beam welding technology, applied in electron beam welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of easy cracking and complicated process in fusion welding connection method, and avoid joint performance. The effect of reducing, relieving welding stress, and inhibiting the formation of brittle phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

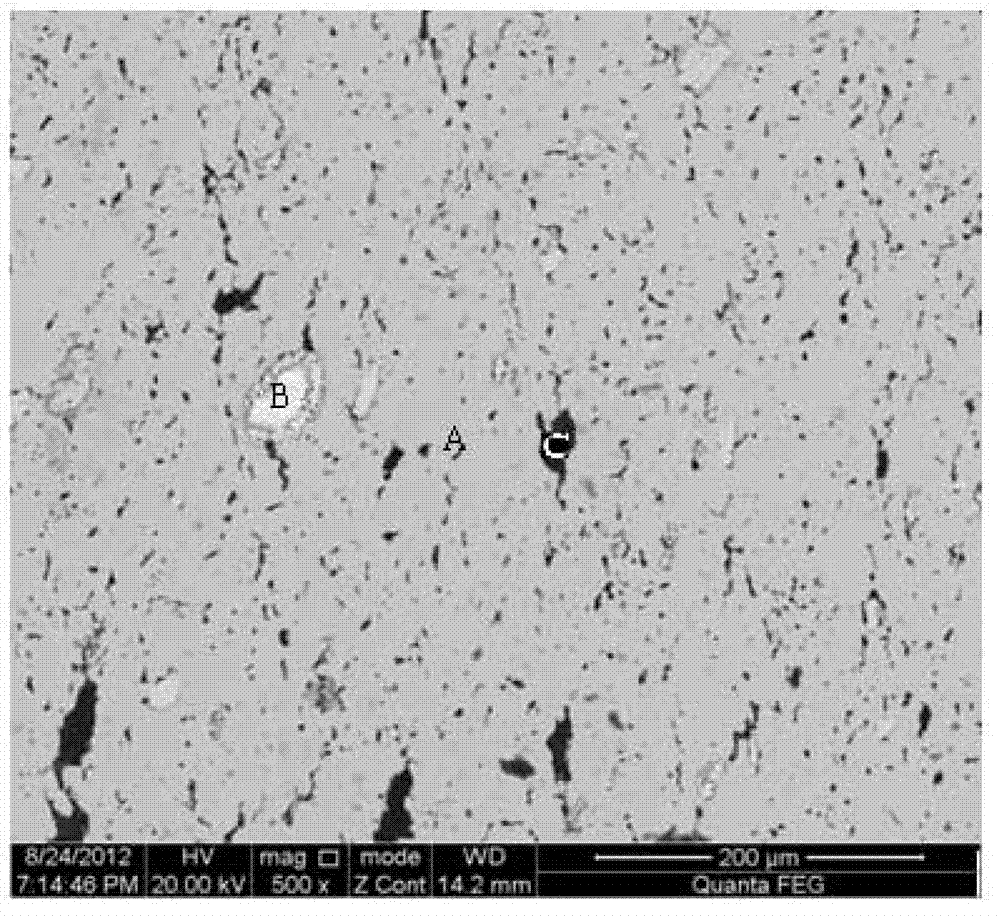

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the electron beam welding YGH-60 cemented carbide of the present embodiment and the manufacture method of 45 steel special-purpose welding materials are specifically carried out according to the following steps:

[0020] 1. Weigh 8.3-8.5% of iron powder, 0.45%-0.55% of niobium powder, 0.75%-0.85% of yttrium powder, 0.45%-0.55% of carbon powder and the rest of nickel powder by weight percentage and add them to Mix in a powder mixer for 0.5 to 1 hour to obtain a mixed powder;

[0021] 2. Add the mixed powder obtained in step 1 into the mold, then put the mold into a hydraulic press, and press it for 120-150 seconds under the condition of a pressure of 300-1000T to obtain a compact;

[0022] 3. Put the compact obtained in step 2 into a vacuum furnace, raise the temperature to 1150-1200°C at a rate of 10-12°C / min and keep it for 1.5-2 hours, and then cool with the furnace to obtain electron beam welded YGH-60 hard Special welding consumables for qu...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the mass content of nickel in the nickel powder in step one is ≥ 99.5%, and the mass content of sulfur in the nickel powder is ≤ 0.003%; other and specific embodiments One is the same.

[0025] In the present embodiment, the mass content of sulfur in the nickel powder is limited, if excessive sulfur is contained in the nickel powder, it will increase the tendency of hot cracks in the welding process of YGH-60 hard alloy and 45 steel on the one hand; on the other hand On the one hand, even if a welded joint without cracks is obtained, the plasticity and toughness of the obtained joint will be greatly affected.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 in that the particle size of the nickel powder in step 1 is 2-3 μm; other aspects are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com