Method for producing cold-rolled steel sheet, cold-rolled steel sheet, and vehicle member

A technology of cold-rolled steel sheet and manufacturing method, applied in the field of cold-rolled steel sheet, can solve the problems of inability to obtain corrosion resistance, failure to obtain high-strength cold-rolled steel sheet with corrosion resistance, improvement of corrosion resistance, etc., and achieve corrosion resistance after coating. Excellent chemical conversion treatment, improved corrosion resistance after painting, and excellent chemical conversion treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093]Steel containing C: 0.125% by mass, Si: 1.5% by mass, Mn: 2.6% by mass, P: 0.019% by mass, S: 0.008% by mass, and Al: 0.040% by mass with the balance consisting of Fe and unavoidable impurities Steel raw material (steel billet) is produced by melting and continuous casting through ordinary refining processes such as a converter and degassing treatment. Next, after reheating the billet to a temperature of 1150-1170°C, hot rolling is performed with the finishing temperature set at 850-880°C, and coiled at a temperature of 500-550°C to form a plate Hot-rolled steel plate with a thickness of 3~4mm. Next, these hot-rolled steel sheets are pickled to remove scale, and then cold-rolled to produce cold-rolled steel sheets with a thickness of 1.8mm. Then, these cold-rolled steel sheets are heated to a soaking temperature of 750~780°C and kept After 40 to 50 seconds, perform continuous annealing at 20 to 30°C / second from the above soaking temperature to the cooling stop temperatu...

Embodiment 2

[0120] The steels A to Z having the composition shown in Table 3 were smelted and continuously cast through a common refining process such as a converter and degassing treatment to form a billet. These billets were hot-rolled under the hot-rolling conditions shown in Table 4 to produce hot-rolled steel sheets with a thickness of 3 to 4 mm, pickled to remove scale on the surface of the steel sheets, and then cold-rolled to obtain sheet thicknesses of 3 to 4 mm. 1.8mm cold-rolled steel plate. Next, these cold-rolled steel sheets were continuously annealed under the conditions shown in Table 4, then pickled under the conditions shown in Table 5, then pickled again, washed with water and dried, and subjected to elongation of 0.7%. Skin pass rolling to obtain No. 1~39 cold-rolled steel sheets.

[0121]

[0122]

[0123]

[0124]

[0125]

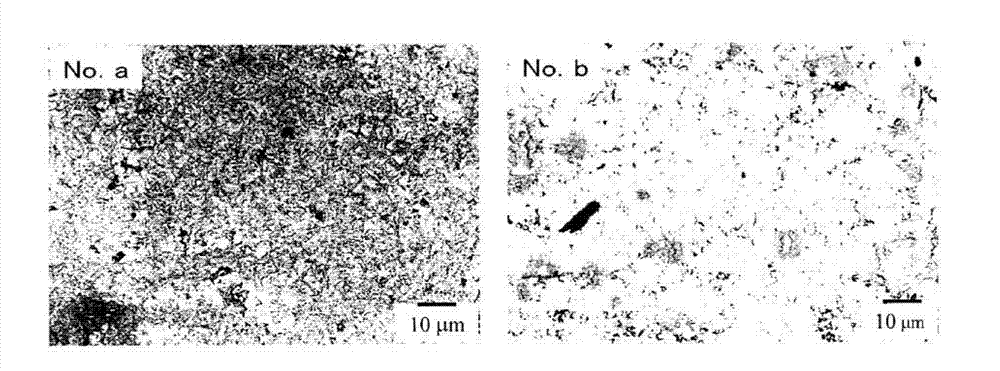

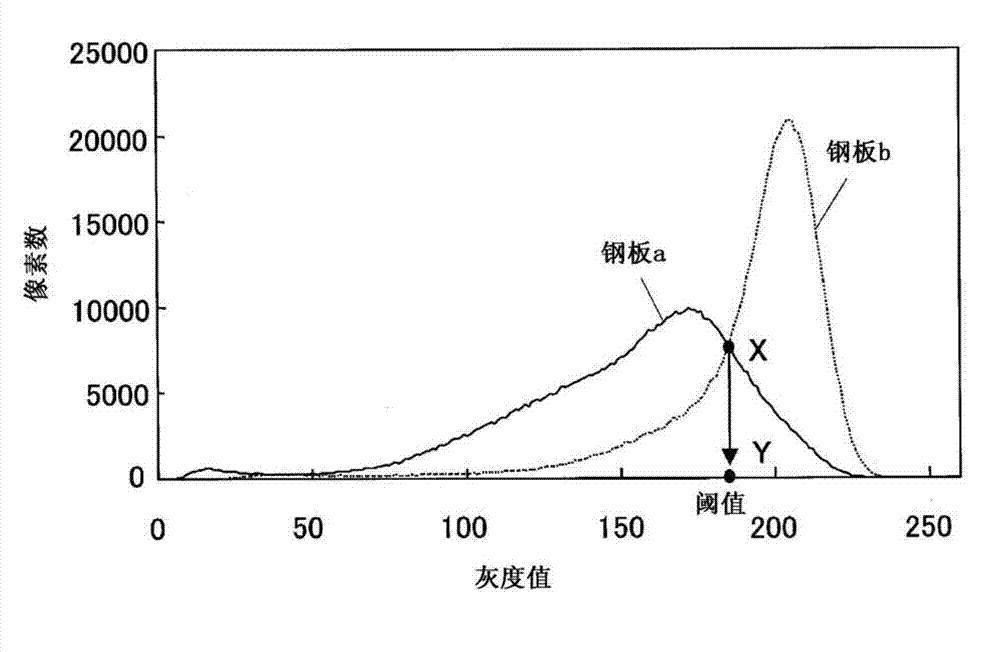

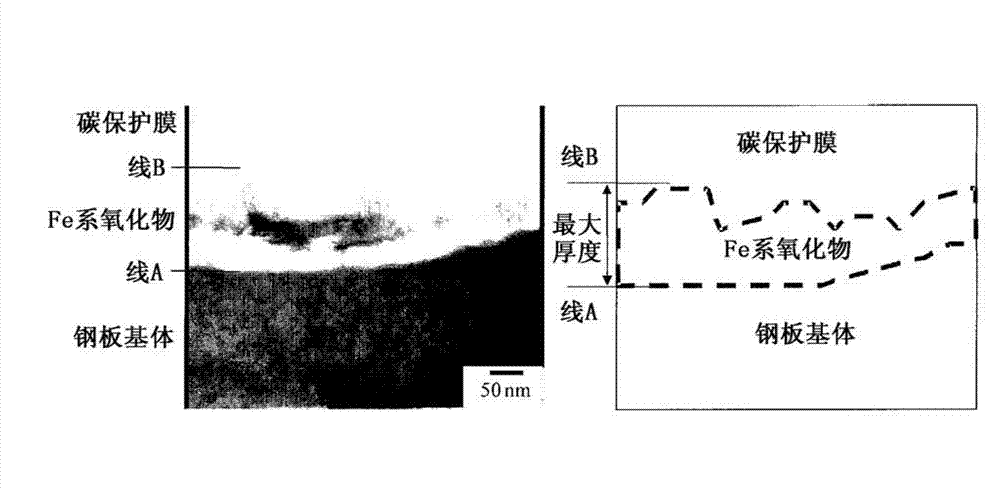

[0126] Test pieces were cut out from the above-mentioned cold-rolled steel sheets obtained in this way, and the surface coverage...

Embodiment 3

[0133]Steel containing C: 0.125% by mass, Si: 1.5% by mass, Mn: 2.6% by mass, P: 0.019% by mass, S: 0.008% by mass, and Al: 0.040% by mass with the balance consisting of Fe and unavoidable impurities Smelting and continuous casting are carried out to produce steel raw materials (billets). After reheating the slab to a temperature of 1150-1170°C, hot rolling is performed with the finish rolling temperature set at 850-880°C, and coiling is performed at a temperature of 500-550°C to produce a plate with a thickness of 3~ 4mm hot rolled steel plate. These hot-rolled steel sheets were pickled to remove scale, and then cold-rolled to obtain cold-rolled steel sheets with a thickness of 1.8 mm. Next, these cold-rolled steel sheets are heated to a soaking temperature of 750 to 780° C., held for 40 to 50 seconds, and then cooled from the above soaking temperature to a cooling stop temperature of 350 to 400° C. at a rate of 20 to 30° C. / second. Keep the continuous annealing for 100 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com