Production method of interconnection structure with materials containing polymer and metal through holes

A polymer material and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost, complicated steps, and long time, and achieve low cost, few manufacturing steps, and simple processing flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

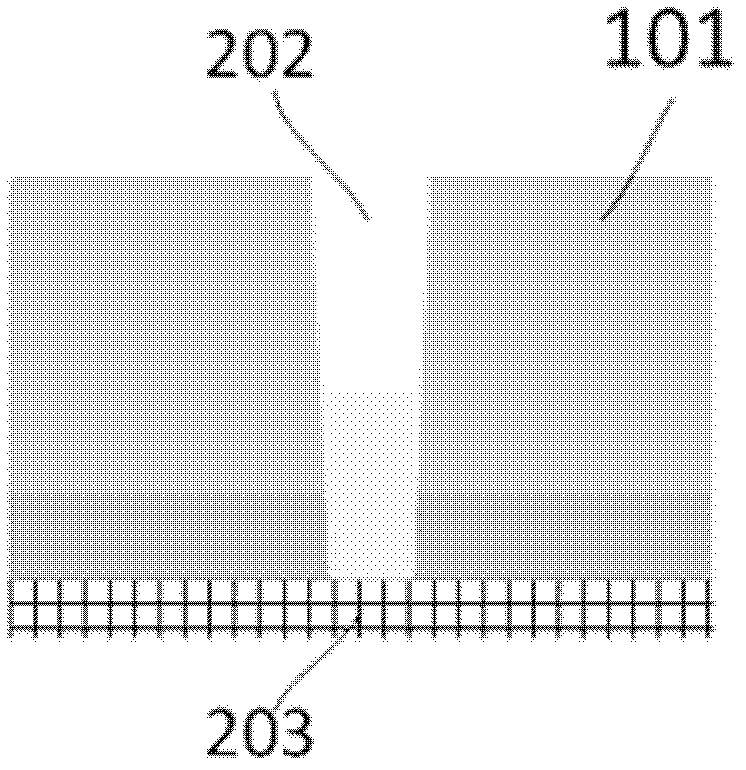

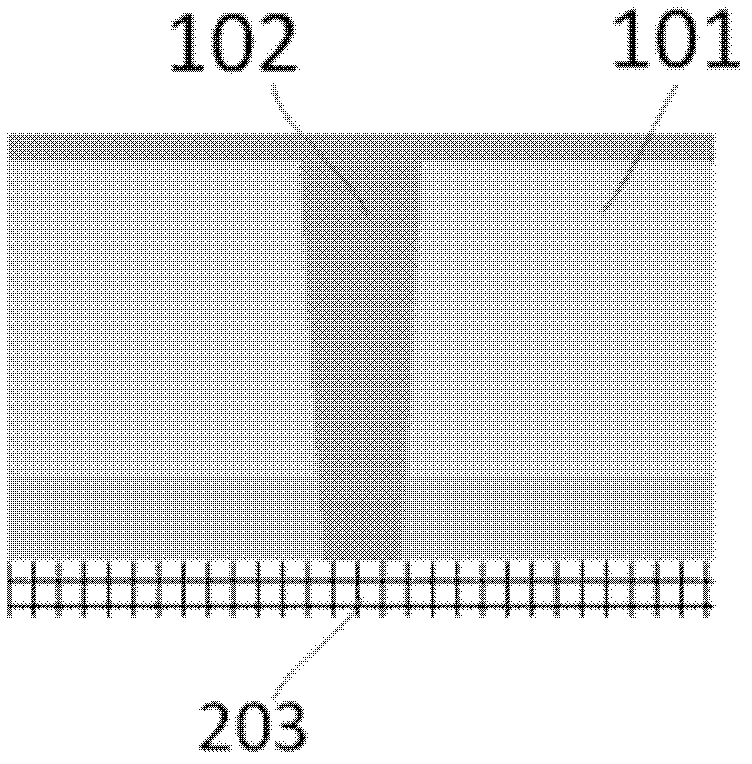

[0031] A method for manufacturing an interconnection structure containing a polymer material and a metal via provided in an embodiment of the present invention includes:

[0032] Step S1, making blind holes or through holes on the substrate. Substrates include glass substrates, silicon wafers, and other semiconductor substrates. Blind or through holes are made using laser drilling, dry etching, sandblasting or mechanical methods.

[0033] Step S2, filling polymer in the blind hole or through hole. Polymer filling is achieved by spin-coating method. Polymers include benzocyclobutene or epoxy based resins.

[0034] Step S3, inserting the metal block into the blind hole or through hole filled with polymer. An auxiliary film is attached to the bottom of the substrate before filling the via holes with polymer. When the metal block is inserted, the polymer in the blind hole or through hole is in a liquid or semi-cured state. Metal blocks include nickel, iron, copper, aluminum,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com