Acetylxylan esterase and application thereof

An acetylxylan ester and deacylating technology, applied in the field of acetylxylan esterase and its application, can solve the problems of poor activity and performance, and limit wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment illustrates the genetically engineered bacteria Escherichia coli ( Escherichia coli ) BL21 - Construction of pET-Cah.

[0046] The genetically engineered bacterium Escherichia coli ( Escherichia coli ) BL21 - pET-Cah, which is the Bacillus subtilis ( Bacillus subtilis ) The gene Cah of acetylxylan esterase from CICC 20034 was transformed by the expression vector pET22b E. coli Genetically engineered bacteria obtained from BL21 (DE3).

[0047] The construction method of the above-mentioned genetically engineered bacteria is as follows: using PCR technology to amplify the Cah gene from the plasmid vector Bacillus subtilis genomic DNA, connecting the Cah gene to the multiple cloning site of the expression vector pET22b to obtain the recombinant plasmid pET-Cah, and then Transformation of recombinant plasmid pET-Cah E. coli BL21 (DE3), the recombinant Escherichia coli, that is, the genetically engineered bacteria that produces acetyl xylan esteras...

Embodiment 2

[0058] This example illustrates the induction expression method of acetyl xylan esterase.

[0059] The specific scheme of utilizing the genetically engineered bacterium of embodiment 1 to induce expression of acetyl xylan esterase is as follows:

[0060] (1) Starting strain: Escherichia coli ( Escherichia coli ) BL21 - pET-Cah;

[0061](2) Seed culture:

[0062] Medium: LB medium: yeast powder 5g / L, peptone 10 g / L, sodium chloride 10 g / L;

[0063] Culture conditions: 250 mL Erlenmeyer flask, liquid volume 50 mL, culture temperature 37 ℃, shaker speed 200 r / min, culture 12 h;

[0064] (3) Fermentation culture:

[0065] Medium composition: LB medium: yeast powder 5g / L, peptone 10 g / L, sodium chloride 10 g / L;

[0066] Culture conditions: inoculum size 1.5% (v / v), fermentation temperature 37 ℃, add isopropyl-β-D-thiogalactopyranoside (IPTG) induction when OD reaches 0.6~0.8, the final concentration of IPTG 1.0 mmol / L, shaker speed 180~250 r / min, fermentation 2-10 h.

[00...

Embodiment 3

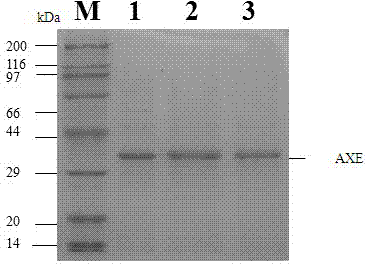

[0080] This example illustrates the purification, molecular weight and multimeric form of acetyl xylan esterase.

[0081] 1. Purification of acetyl xylan esterase:

[0082] Acetyl xylan esterase was concentrated and purified by 50%-80% (w / v) ammonium sulfate fractional precipitation and ultrafiltration. The purification steps are as follows:

[0083] (1) 50%-80% ammonium sulfate fractional precipitation: take the broken solution, centrifuge at 12000g for 30min; transfer 50mL supernatant to a 100mL beaker, slowly add 50mL of SAS solution (saturated ammonium sulfate solution) while stirring, After the solution was stirred on a magnetic stirrer for 6 hours, it was placed in a 4-degree refrigerator overnight to fully precipitate. The protein solution was centrifuged at 10000 g for 30 min. Transfer 50mL of the supernatant to a new beaker, slowly add 75mL of SAS solution while stirring, so that the final concentration is 80% ammonium sulfate solution, put the solution on a magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com