Method for utilizing thermally induced phase separation technology to prepare porous ceramic

A technology of thermally induced phase separation and porous ceramics, which is applied in the direction of ceramic products, applications, household appliances, etc., can solve the problems of affecting performance, difficult to control the shape of pores, and uneven distribution of pores, so as to reduce production cycle, single raw material, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

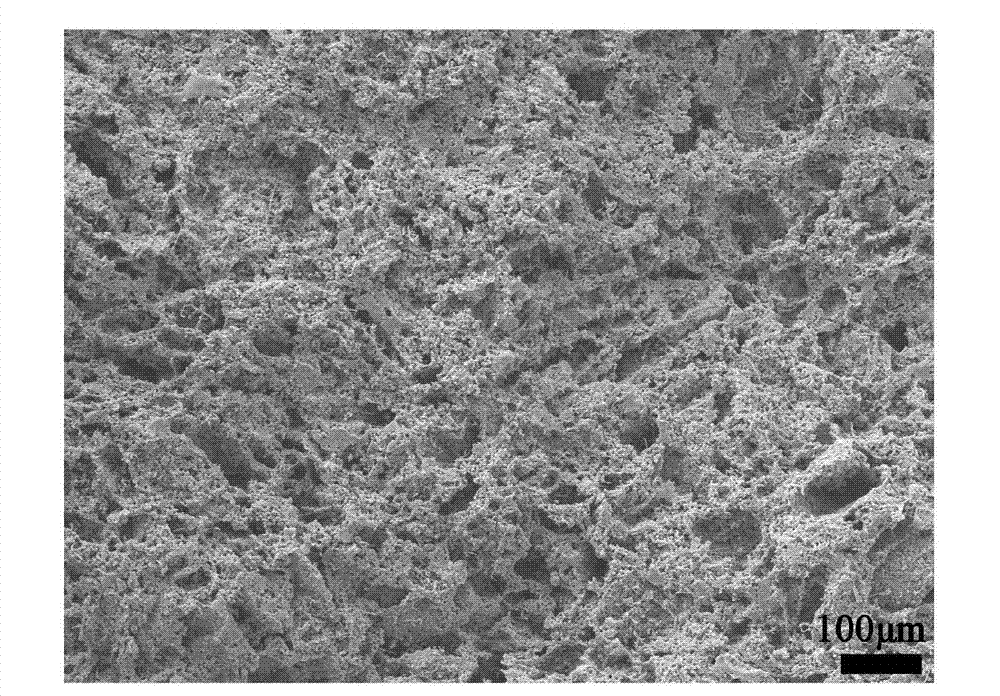

[0030] according to figure 1 The process shown in this example is a method for preparing porous ceramics using thermally induced phase separation technology. The specific implementation process is as follows:

[0031] (1) Configuration of saturated benzoic acid solution: Weigh 100g of absolute ethanol, add 140g of BA to it, place in a water bath crucible at 60°C, and stir with an electromagnetic stirrer until BA is completely dissolved to form a clear solution;

[0032] (2) Preparation of ceramic slurry: mix 150g of silicon nitride ceramics and their sintering aids (142.5g of silicon nitride ceramics, sintering aids Y 2 o 3 7.5g) into the prepared solution, add 4.5g of dispersant PVP to the solution, stir with an electromagnetic stirrer at 60°C for 4h, and the stirring speed is 200r / min;

[0033] (3) Forming the green body: Place the evenly stirred ceramic slurry at 30°C to cause solid-liquid phase separation in the supersaturated solution to precipitate the pore-forming age...

Embodiment 2

[0038] according to figure 1 The process shown in this example is a method for preparing porous ceramics using thermally induced phase separation technology. The specific implementation process is as follows:

[0039] (1) Configuration of saturated benzoic acid solution: Weigh 100g of absolute ethanol, add 140g of BA to it, place in a water bath crucible at 60°C, and stir with an electromagnetic stirrer until BA is completely dissolved to form a clear solution;

[0040] (2) Preparation of ceramic slurry: mix 150g of silicon nitride ceramics and their sintering aids (142.5g of silicon nitride ceramics, sintering aids Y 2 o 3 7.5g) into the prepared solution, add 4.5g of dispersant PVP to the solution, stir for 3 hours at 60°C with an electromagnetic stirrer, and the stirring speed is 300r / min;

[0041] (3) Body forming: Cool the uniformly stirred ceramic slurry to 40°C at a cooling rate of 5°C / min, the supersaturated solution undergoes solid-liquid phase separation, and preci...

Embodiment 3

[0046] according to figure 1 The process shown in this example is a method for preparing porous ceramics using thermally induced phase separation technology. The specific implementation process is as follows:

[0047] (1) Configuration of saturated benzoic acid solution: Weigh 100g of absolute ethanol, add 140g of BA to it, place in a water bath crucible at 60°C, and stir with an electromagnetic stirrer until BA is completely dissolved to form a clear solution;

[0048] (2) Preparation of ceramic slurry: Mix 150g of silicon powder, alumina powder and sintering aid (Si: Al 2 o 3 =30:67,Y2 o 3 Accounting for 3% of the mass of the mixture), pour it into the prepared solution, add 4.5g of dispersant PVP to the solution, stir for 2 hours at 60°C with an electromagnetic stirrer, and the stirring speed is 400r / min;

[0049] (3) Green body forming: Cool the uniformly stirred ceramic slurry to 50°C at a cooling rate of 5°C / min, the supersaturated solution undergoes solid-liquid phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com