Ambient pressure drying method for rapidly preparing SiO2 aerogel

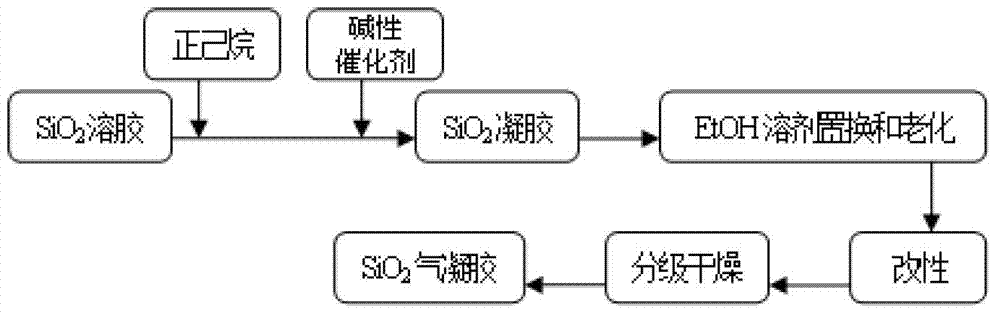

An atmospheric pressure drying and airgel technology, which is applied in the field of nanomaterial preparation and nanometer mesoporous material preparation, can solve the problems of long atmospheric pressure drying process cycle, high production cost and poor repeatability, so as to improve the efficiency of solvent replacement and production Cost increase, effect of improving surface modification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

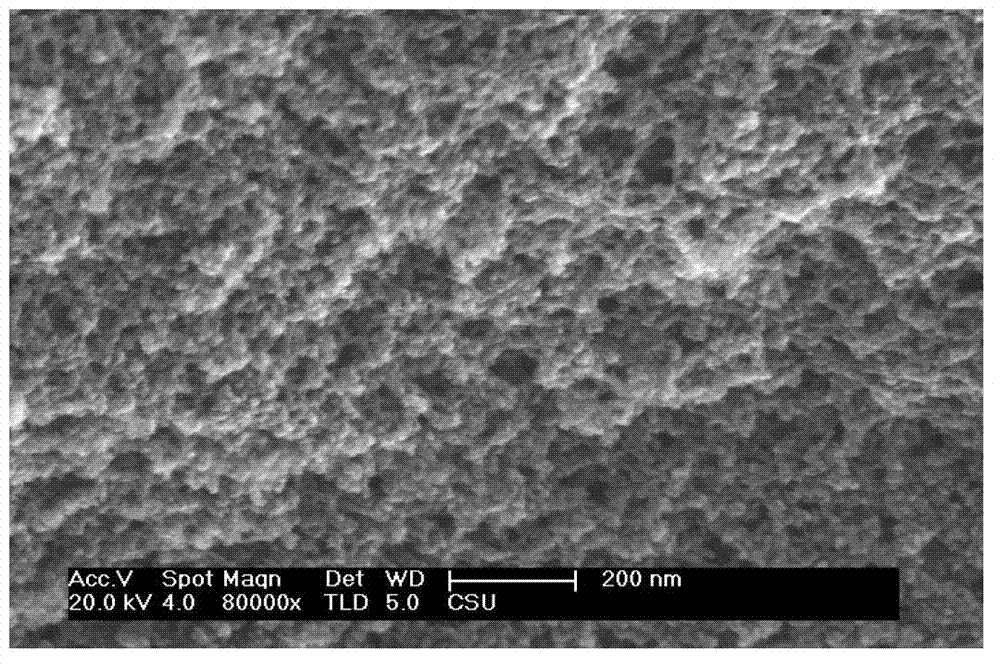

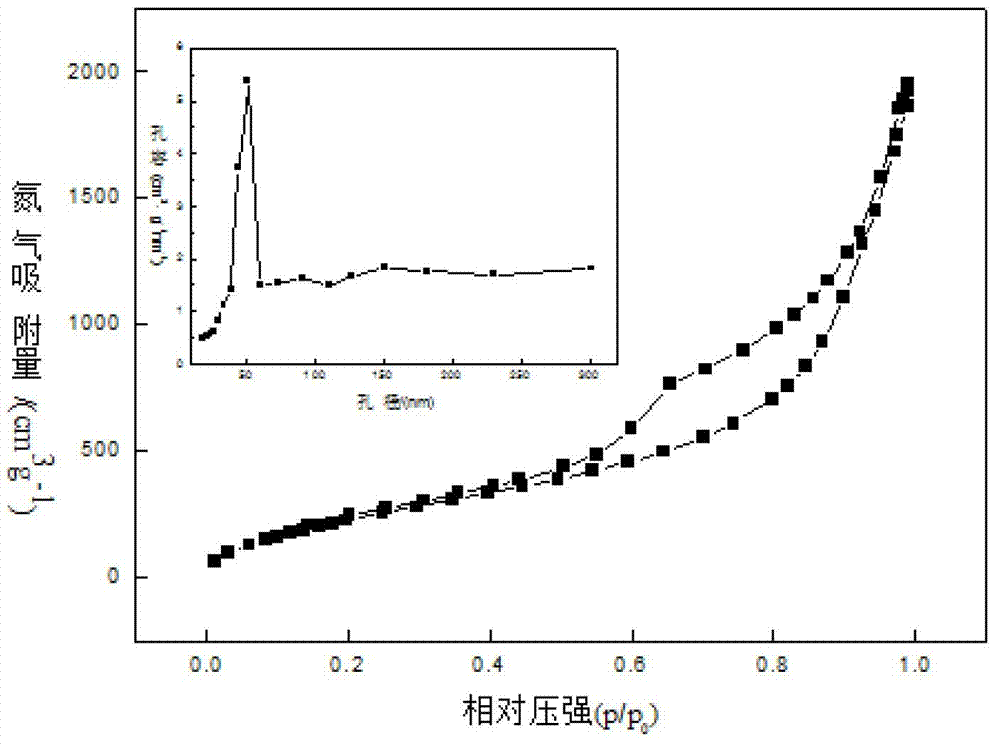

[0037] Mix silicon alkoxide, absolute ethanol, deionized water, n-hexane and 0.1mol / L hydrochloric acid and then perform hydrolysis reaction to prepare sol. The hydrolysis time is 4 hours, and the hydrolysis temperature is 25°C. The molar ratio of silicon alkoxide and hydrochloric acid 1:9×10 -5 , the molar ratio of silicon alkoxide, absolute ethanol, deionized water and n-hexane is 1:4:4:1.5. In the prepared sol, add an appropriate amount of 0.1mol / L ammonia water, wherein the molar ratio of silicon alkoxide and ammonia water is 1:1.8×10 -4 , after stirring for 5 minutes, let it stand until it gels. The prepared gel was placed in absolute ethanol and aged at 50° C. for 10 h, which was equivalent to one replacement. A mixed solution of trimethylchlorosilane (TMCS) and n-hexane was used as a surface modifier to modify the aged gel, where the molar ratio of TMCS and n-hexane was TMCS:N-hexane=1:10, each time The modification time is 3h, and the modification is performed twice...

Embodiment 2

[0040] In this embodiment, on the basis of Example 1, the amount of n-hexane added is changed.

[0041] Mix silicon alkoxide, absolute ethanol, deionized water, n-hexane and 0.1mol / L hydrochloric acid and then perform hydrolysis reaction to prepare sol. The hydrolysis time is 4 hours, and the hydrolysis temperature is 25°C. The molar ratio of silicon alkoxide and hydrochloric acid 1:9×10 -5 , the molar ratio of silicon alkoxide, absolute ethanol, deionized water and n-hexane is 1:4:4:1. In the prepared sol, add an appropriate amount of 0.1mol / L ammonia water, wherein the molar ratio of silicon alkoxide and ammonia water is 1:1.8×10 -4 , stir evenly and let stand until it gels. The prepared alcohol gel was placed in absolute ethanol, replaced twice with ethanol solvent for 2 hours each time, and aged at 50° C. for 10 hours. A mixed solution of trimethylchlorosilane (TMCS) and n-hexane was used as a surface modifier to modify the aged gel, where the molar ratio of TMCS and n-...

Embodiment 3

[0044] In this embodiment, on the basis of Example 1, the amount of n-hexane added is changed.

[0045] Mix silicon alkoxide, absolute ethanol, deionized water, n-hexane and 0.1mol / L hydrochloric acid and then perform hydrolysis reaction to prepare sol. The hydrolysis time is 4 hours, and the hydrolysis temperature is 25°C. The molar ratio of silicon alkoxide and hydrochloric acid 1:9×10 -5 , the molar ratio of silicon alkoxide, absolute ethanol, deionized water and n-hexane is 1:4:4:2. In the prepared sol, add an appropriate amount of 0.1mol / L ammonia water, wherein the molar ratio of silicon alkoxide and ammonia water is 1:1.8×10 -4 , stir evenly and let stand until it gels. The prepared gel was placed in absolute ethanol, replaced twice with ethanol solvent for 3 hours each time, and aged at 50° C. for 10 hours. A mixed solution of trimethylchlorosilane (TMCS) and n-hexane was used as a surface modifier to modify the aged gel, where the molar ratio of TMCS and n-hexane w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com